Drilling rig integrated control system based on b‑s architecture with multi-ring redundant nesting

An integrated control system and ring network technology, applied in the direction of drilling automatic control system, transmission system, ring network, etc., can solve the problems of response speed, system fault tolerance, equipment fault-free working time can not meet the actual needs, etc., to ensure uninterrupted Operation, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

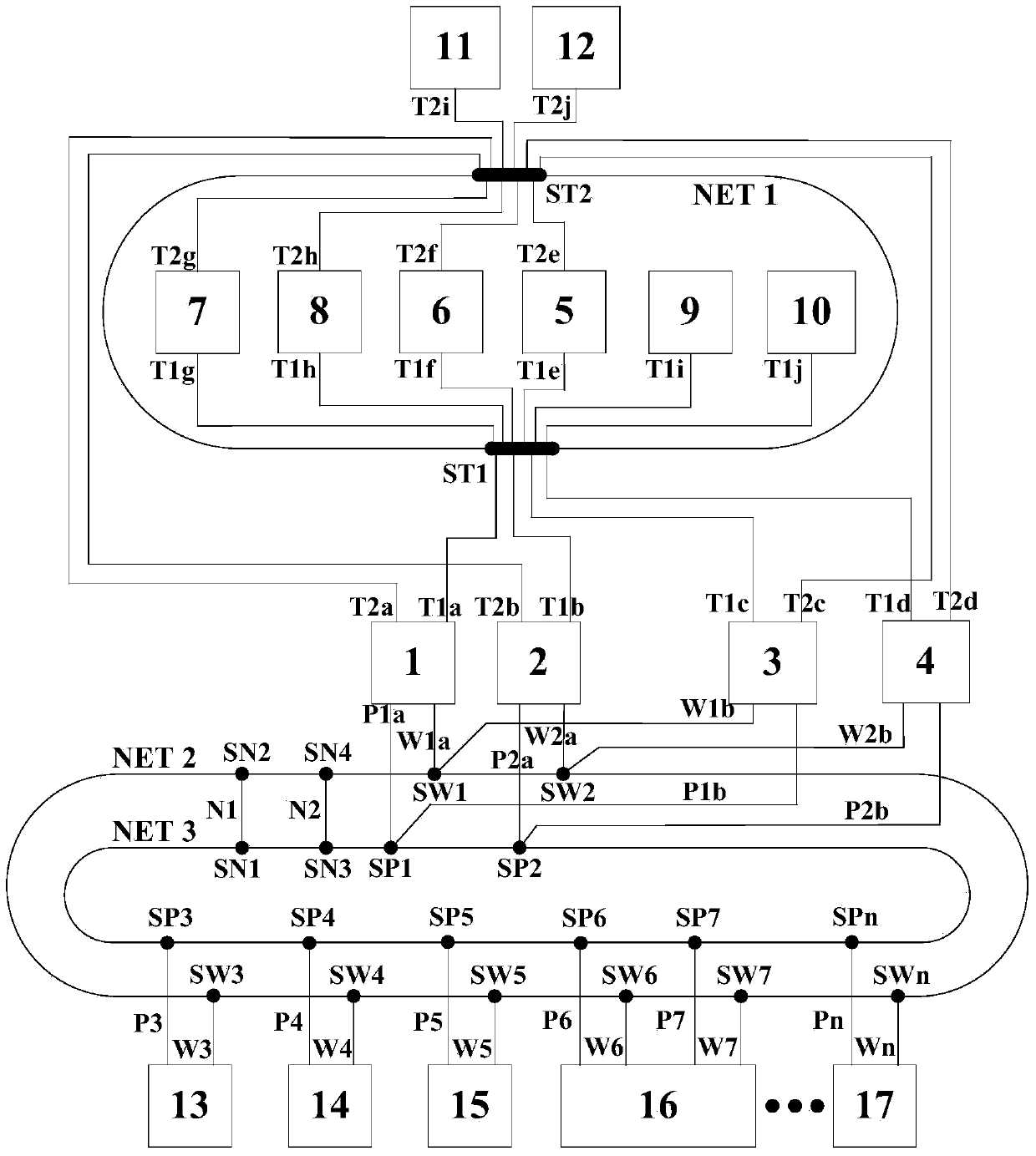

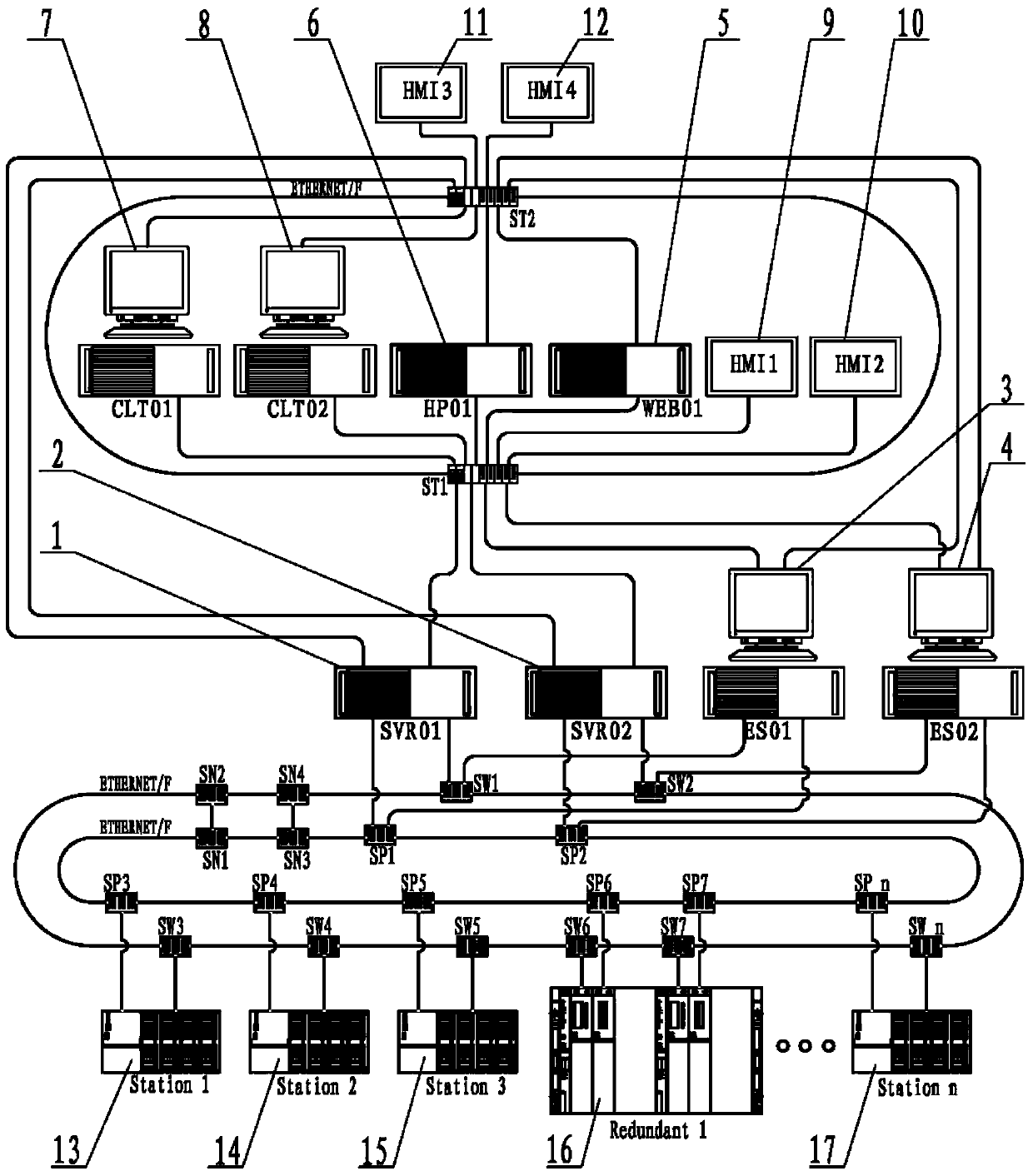

[0034] refer to figure 1 , the structure of the integrated control system of the present invention is to comprise terminal ring communication network NET1, lower ring communication network NET2 and lower redundant ring communication network NET3, hereinafter referred to as NET1 network, NET2 ring network and NET3 ring network respectively, wherein NET1 network It is called the upper computer system, and the NET3 ring network and the NET2 ring network are called the lower computer system together;

[0035] NET1 network includes switches ST1 and ST2, switches ST1 and ST2 are interconnected (parallel connection); NET2 ring network includes switches SN2, SN4, SW1, SW2...SWn, switches SN2, SN4, SW1, SW2...SWn are interconnected in turn (parallel connection); NET3 ring network includes switches SN1, SN3, SP1, SP2...SPn interconnected in turn, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com