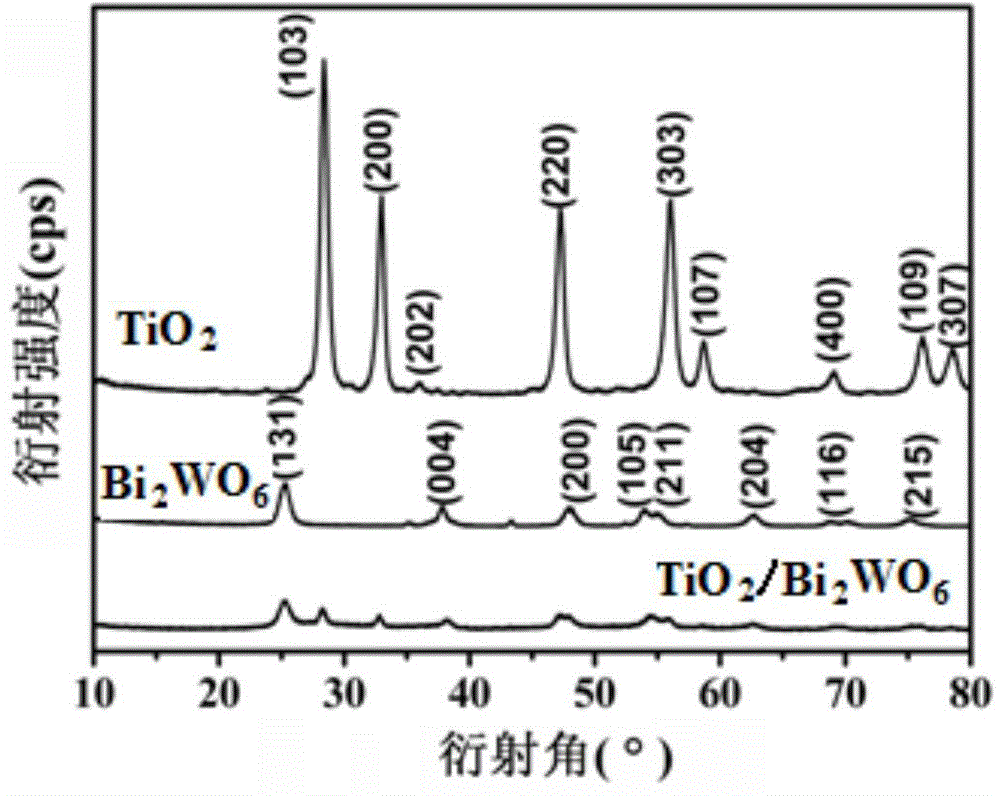

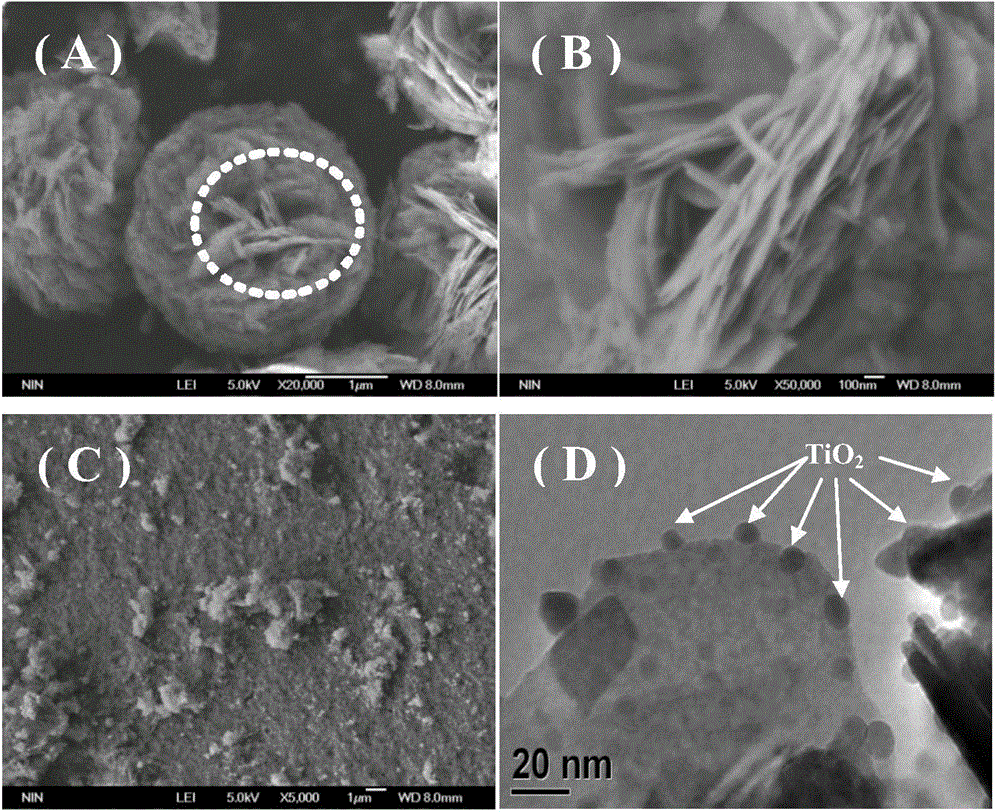

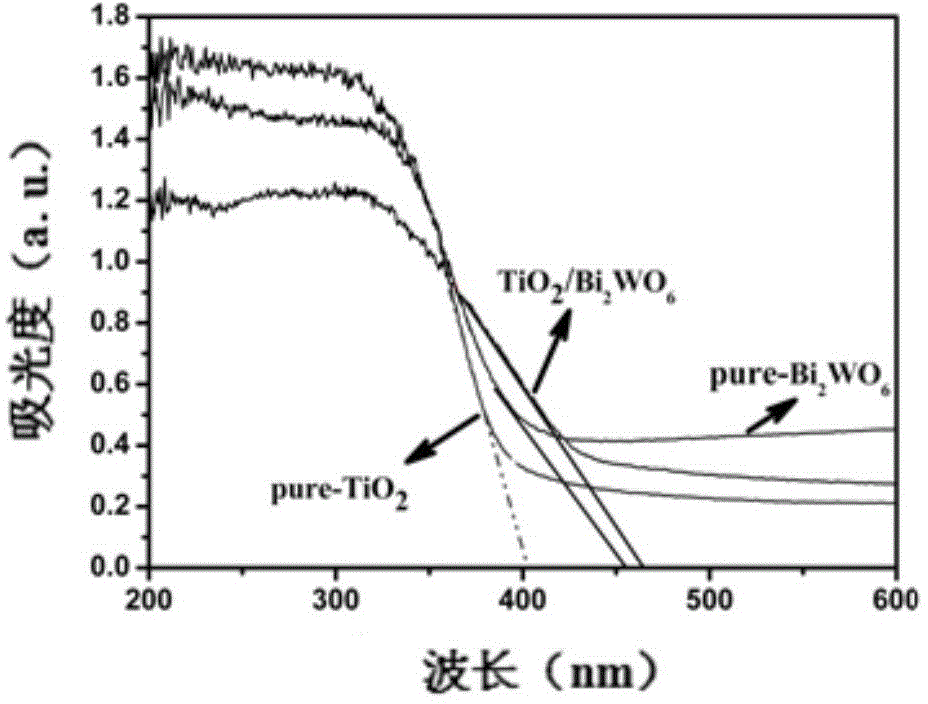

Preparation method of bismuth tungstate-titanium dioxide heterojunction composite photocatalysis material

A composite photocatalysis and titanium dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. The effect of improvement, good controllability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Weigh 0.98g Bi(NO 3 ) 3 ·5H 2 O solid, dissolve it in the prepared 20mL, 0.4mol / L HNO 3 solution, stirred at 40°C until Bi(NO 3 ) 3 ·5H 2 O dissolved, then added 10mL, 25g / L (NH 4 ) 10 W 12 o 41 ·5H 2 O aqueous solution, after continuous stirring for 2h, liquid a was obtained;

[0030] Step 2: Add 4mL C 16 h 36 o 4 Ti and 16mL CH 3 CH 2 OH was mixed to obtain liquid b, which was added dropwise with 1.5mL CH under stirring 3 COOH, 1ml distilled water and 5ml CH 3 CH 2 In liquid c mixed with OH, continue to stir for 20 minutes after dripping, then take 1 / 9 of the volume of liquid a to mix with it, continue to stir for 30 minutes, transfer the mixed liquid into a hydrothermal reaction kettle, seal the kettle, put it into an electric heating constant temperature blast React in a drying oven at 180°C for 15h. After the reaction, centrifuge and precipitate, wash, vacuum dry (dry at 80°C for 16h), and grind to obtain a powdered bismuth tungstate-titan...

Embodiment 2

[0032] Step 1: Weigh 0.98g Bi(NO 3 ) 3 ·5H 2 O solid, dissolve it in the prepared 20mL, 0.4mol / L HNO 3 solution, stirred at 40 °C until solid Bi(NO 3 ) 3 ·5H 2 O dissolved, followed by adding 10mL, 25g / L (NH 4 ) 10 W 12 o 41 ·5H 2 O aqueous solution, after continuous stirring for 2.5h, liquid a was obtained;

[0033] Step 2: Add 4mL C 16 h 36 o 4 Ti and 16mL CH 3 CH 2 OH was mixed to obtain liquid b, which was added dropwise with 1.5mL CH under stirring 3 COOH, 1ml distilled water and 5ml CH 3 CH 2 In liquid c mixed with OH, continue to stir for 40 minutes after dripping, then take 5 / 9 of the volume of liquid a to mix with it, continue to stir for 1 hour, transfer the mixed liquid into a hydrothermal reaction kettle, seal the kettle, and put it into an electric heating constant temperature blast React in a drying oven at 200°C for 10h. After the reaction, centrifuge and precipitate, wash, vacuum dry (100°C for 12h), and grind to obtain powdered bismuth tungst...

Embodiment 3

[0035] Step 1: Weigh 0.98g Bi(NO 3 ) 3 ·5H 2 O solid, dissolve it in the prepared 20mL, 0.4mol / L HNO 3 solution, stirred at 40 °C until solid Bi(NO 3 ) 3 ·5H 2 O dissolved, then added 10mL, 25g / L (NH 4 ) 10 W 12 o 41 ·5H 2 O aqueous solution, after continuous stirring for 2h, liquid a was obtained;

[0036] Step 2: Add 4mL C 16 h 36 o 4 Ti and 16mL CH 3 CH 2 OH was mixed to obtain liquid b, which was added dropwise with 1.5mL CH under stirring 3 COOH, 1ml distilled water and 5mL CH 3 CH 2 In liquid c mixed with OH, continue to stir for 30 minutes after dripping, then take liquid a to mix with it, continue to stir for 1.5 hours, transfer the mixed liquid into a hydrothermal reaction kettle, seal the kettle, and put it in an electric heating constant temperature blast drying box for 190 React at ℃ for 12 hours. After the reaction, centrifuge to separate the precipitate, wash, vacuum dry (100 ℃ for 12 hours), and grind to obtain powdered bismuth tungstate-titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com