Three-roll plate- rolling machine

A kind of plate machine and rolling technology, which is used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of not being able to control the plate in real time, affecting the forming accuracy of the plate, and the deviation of the plate, so as to reduce friction, prolong the service life, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

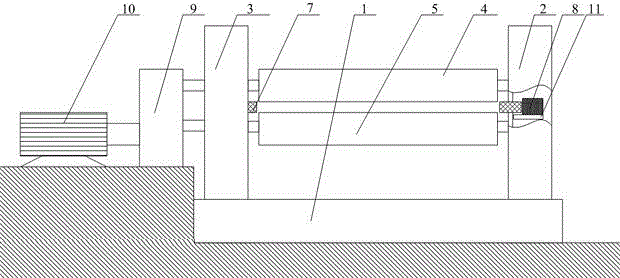

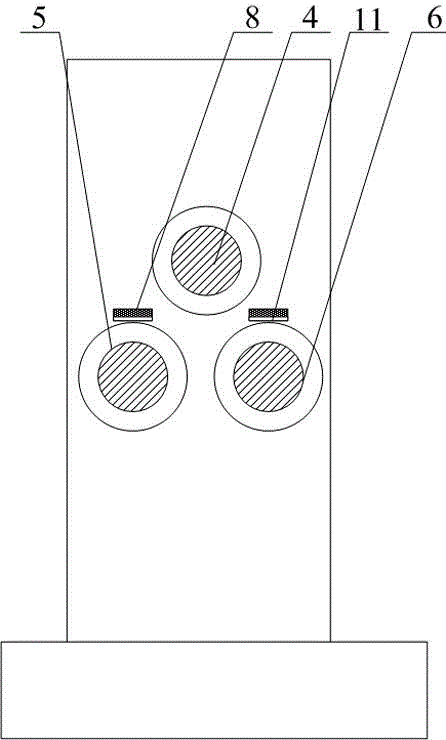

[0012] Such as figure 1 with 2 As shown, the three-roll plate bending machine of the present invention includes a right support 2 , a left support 3 , an upper roll 4 , a first lower roll 5 , a second lower roll 6 , a transmission gearbox 9 and a drive motor 10 . The right bracket 2 and the left bracket 3 are fixedly installed on the base 1 . The first lower roller 5 and the second lower roller 6 are installed in parallel between the right bracket 2 and the left bracket 3 through the connecting shaft; the upper roller 4 is installed between the right bracket 2 and the left bracket 3 through the connecting shaft, and the upper roller 4 is located on the right The bracket 2 and the top of the left bracket 3 are arranged symmetrically among the three.

[0013] The connecting shafts of the first lower roller 5, the second lower roller 6 and the upper roller 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com