Particle feeding mechanism

A feeding mechanism and particle technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve problems affecting packaging and picking, cost increase, overlapping, etc., to avoid reset and skew, improve use efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

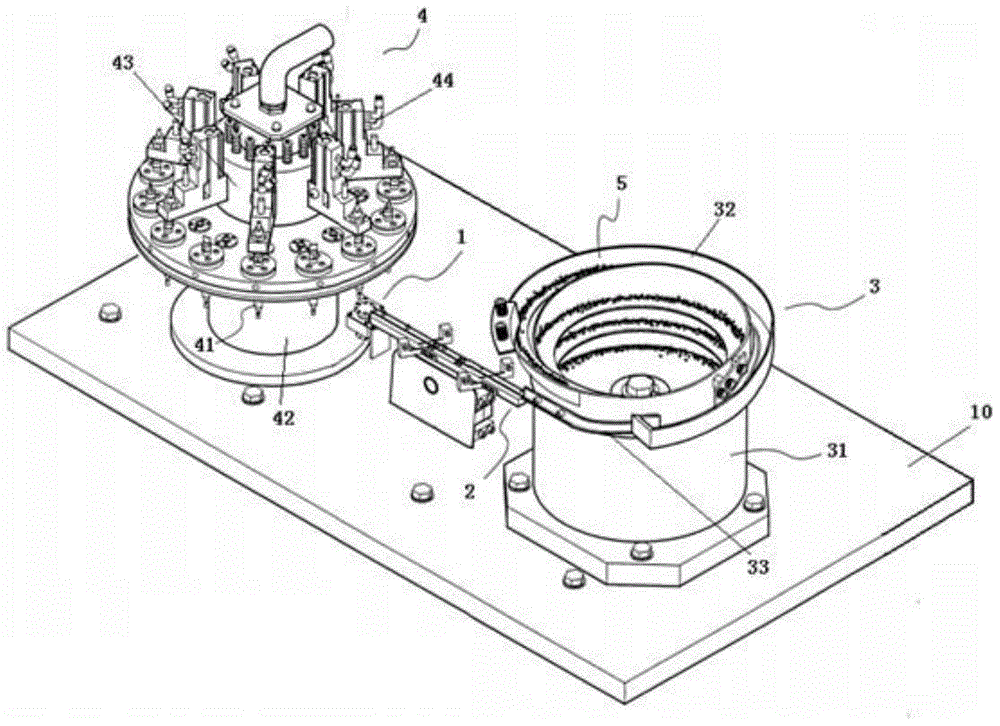

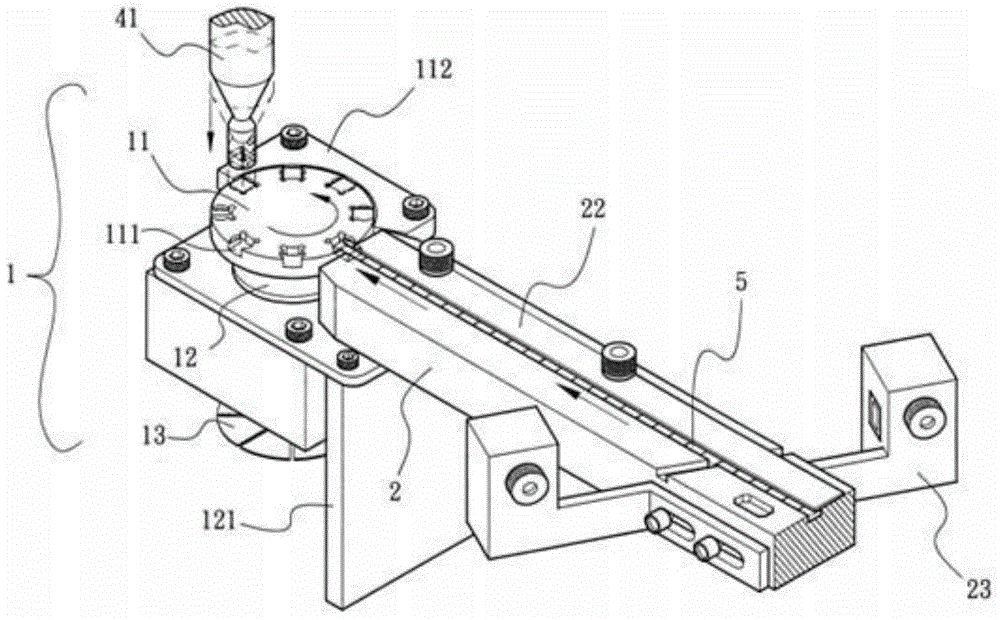

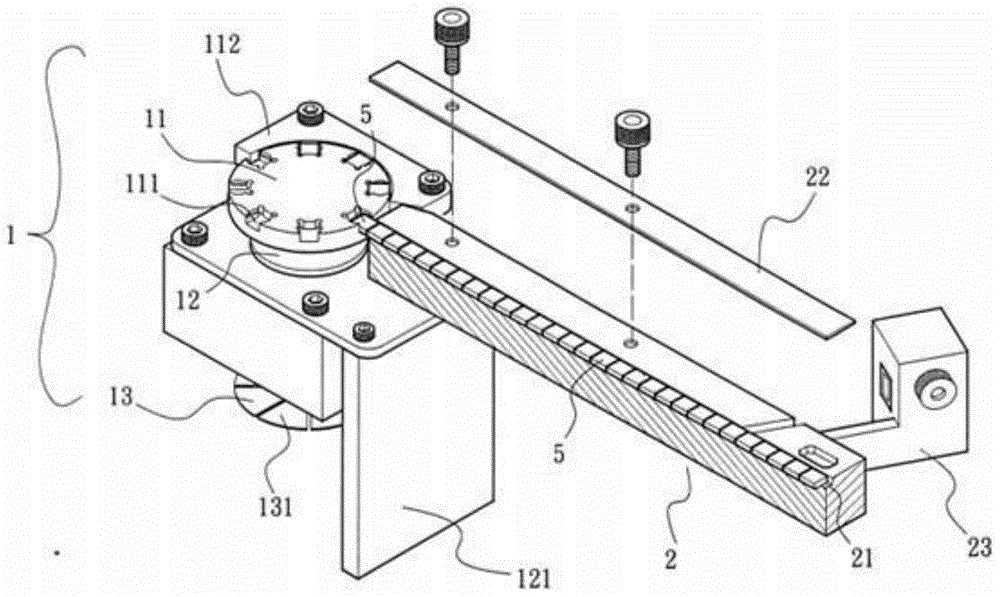

[0021] see figure 1 , shows the particle feeding mechanism of the present invention.

[0022] The particle feeding mechanism includes a base 10, a vibrating discharge device 3, a conveying structure and a pick-up device 4. One side of the base 1 is provided with a vibrating discharge device 3, and the vibrating discharge device 3 includes a cylindrical housing 31, the housing 31 is fixed to the base 1 by a plurality of bolts, the upper end of the housing 31 is provided with a spiral rising track 32, and the housing 31 is provided with a vibrating motor (not shown ), the end of the spiral rising track 32 is connected with a discharge strip 33, so that when the vibrating discharge device 3 vibrates, the particles 5 in the housing 31 jump up in sequence according to the rising track 32 until Enter in the discharge bar 33.

[0023] The other side of the base 1 is provided with a pick-up device 4, the pick-up device 4 includes a housing 42, the housing 42 is provided with a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com