Method for judging cohesive zone formation process in blowing-in process of blast furnace

A soft-melting belt and blast furnace technology, applied in the field of blast furnace ironmaking, can solve problems such as large economic losses, collapse of materials, pipelines and suspended materials, and influence on the furnace opening process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

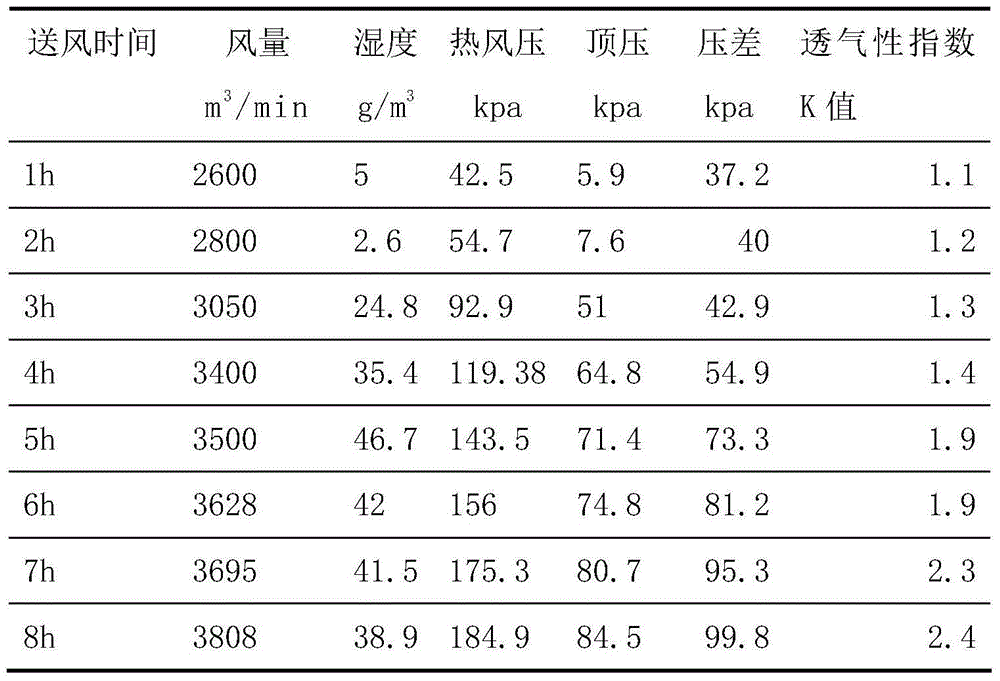

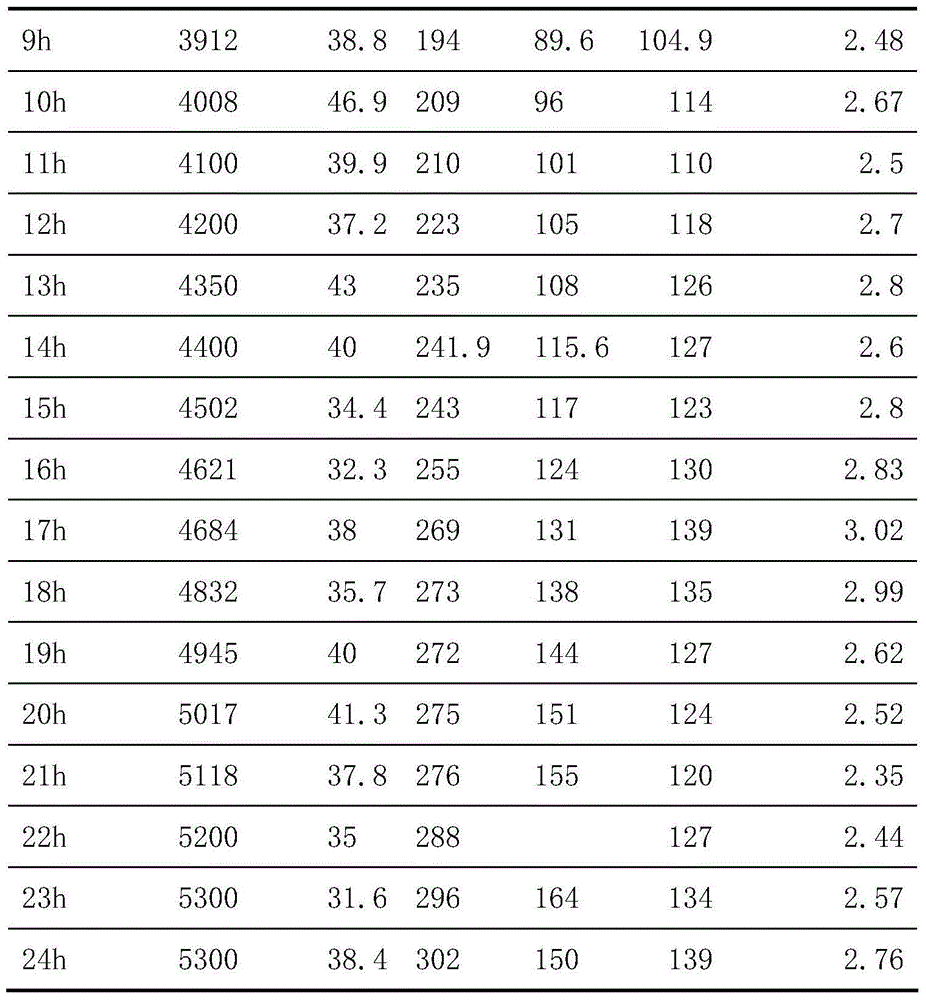

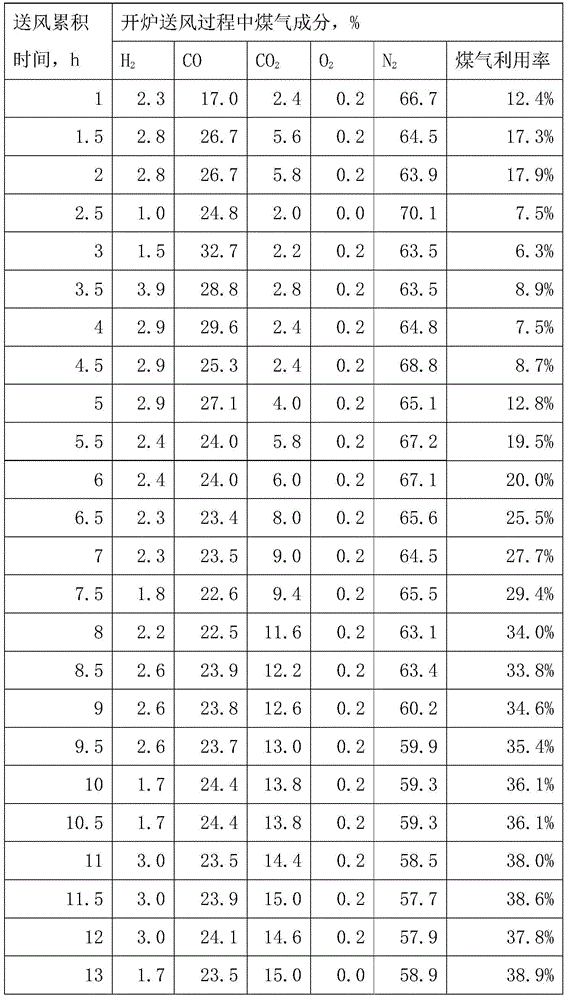

[0016] The air supply situation during the start-up process of a large blast furnace in a domestic factory. The blast furnace was ignited to supply air at 10:00. After the air supply, the furnace material began to slowly descend. At 11:30, the 4# iron mouth began to blow gas, and the cumulative wind was 1118Km 3 , 11:53 blast furnace gas delivery, 12:20 top pressure after gas delivery from normal pressure to high pressure. 17:05 Furnace top gas analysis CO 2 The content increased significantly, the wind pressure began to rise at 18:00, and the soft melting zone began to form, with a cumulative wind volume of 2193Km 3 , The maximum pressure difference is 145kpa, which realizes the smooth transition of the formation process of the furnace soft melt zone.

[0017] CO in gas from 17:05 2 At 18:05, the wind pressure increased significantly. At 19:05, the top temperature increased rapidly. At 20:05, the wind pressure decreased. The CO2 content and gas utilization rate continued to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com