Preparation method of novel multifunctional silk filtering material

A filter material and multifunctional technology, which is applied in the field of preparation of new multifunctional silk filter materials, can solve the problems of poor filter material functionality and functional dependence on silk, etc., to achieve improved cohesion, high adsorption and air permeability, The effect of improving functionality and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

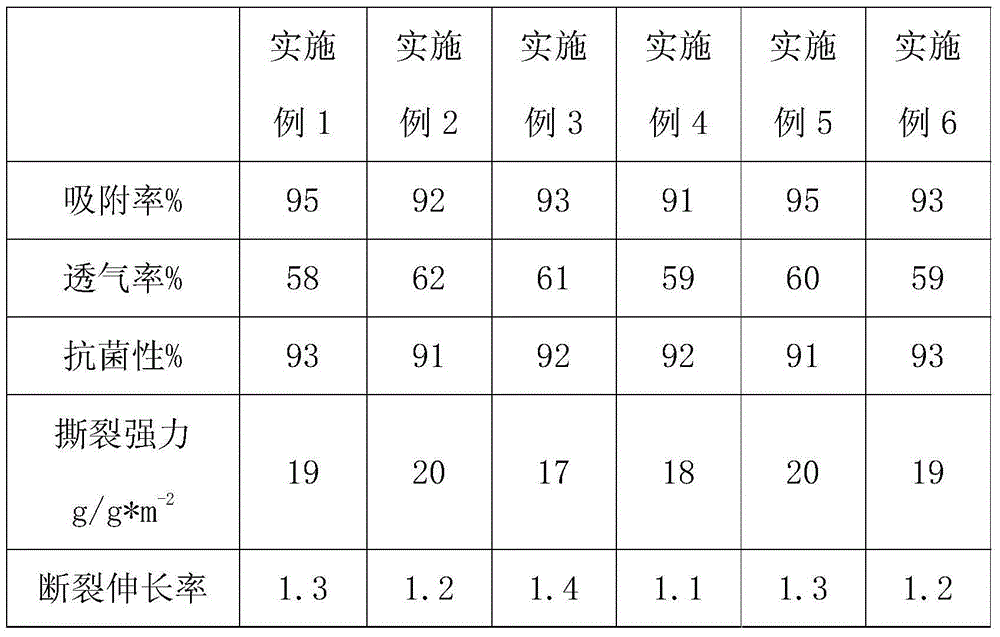

Examples

Embodiment 1

[0026] The waste silk below 6 cm is degummed with 0.08 g / L sodium carbonate solution after removing impurities, washed and dried to obtain degummed silk bundles.

[0027] Soak the degummed silk bundles in a mixed solution of titanium dioxide sol and silk protein at a bath ratio of 1:40 for 30 minutes, wherein the mass fraction of silk protein is 15%, and the mass fraction of titanium dioxide sol is 8%. Then the silk bundle is taken out, soaked in a gelling agent with a molar ratio of 1:5 of carboxylic acid and polyethylene glycol, the amount of the gelling agent is 1 / 50 of the volume of the mixed solution of titanium dioxide sol and silk protein, After the fibroin is gelled, it is taken out to obtain a gel-treated silk bundle.

[0028] Remove the excess gel on the surface of the gel-treated silk bundle, pressurize it with a heating roller, heat and solidify at 30°C, and after spunlace treatment with a density of 16 strands / cm and a pore diameter of 0.15mm, dry it at 70°C to ob...

Embodiment 2

[0030] The waste silk below 6 cm is degummed with 0.08 g / L sodium carbonate solution after removing impurities, washed and dried to obtain degummed silk bundles.

[0031] Soak the degummed silk in a mixed solution of titanium dioxide sol and silk protein at a bath ratio of 1:40 for 60 minutes, wherein the mass fraction of silk protein is 10%, and the mass fraction of titanium dioxide sol is 5%. Then the silk bundle is taken out and soaked in a gelling agent with a molar ratio of carboxylic acid and polyethylene glycol of 1:5. The amount of the gelling agent is 1 / 50 of the volume of the mixed solution. After the silk protein gels, Take out to obtain gel-treated silk bundles.

[0032] Remove the excess gel on the surface of the gel-treated silk, pressurize it with a heating roller, heat and solidify at 50°C, and after spunlace treatment with a density of 16 strands / cm and a pore diameter of 0.15mm, dry it at 80°C to obtain a thickness of 3cm, a new multifunctional silk filter m...

Embodiment 3

[0034] The waste silk below 6 cm is degummed with 0.08 g / L sodium carbonate solution after removing impurities, washed and dried to obtain degummed silk bundles.

[0035] Soak the degummed silk in a mixed solution of titanium dioxide sol and silk protein at a bath ratio of 1:40 for 40 minutes, wherein the mass fraction of silk protein is 12%, and the mass fraction of titanium dioxide sol is 6%. Then the silk bundle is taken out and soaked in a gelling agent with a molar ratio of carboxylic acid and polyethylene glycol of 1:5. The amount of the gelling agent is 1 / 50 of the volume of the mixed solution. After the silk protein gels, Take it out to get gel-treated silk.

[0036] Remove the excess gel on the surface of the gel-treated silk bundle, pressurize it with a heating roller, heat and solidify at 40°C, and after spunlace treatment with a density of 16 strands / cm and a pore size of 0.15mm, dry it at 75°C to obtain a thickness It is a new multi-functional silk filter materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com