Microscopic quality detection method for printing, platemaking and imaging

A technology of micro-quality and detection methods, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as quality assessment methods that are not formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

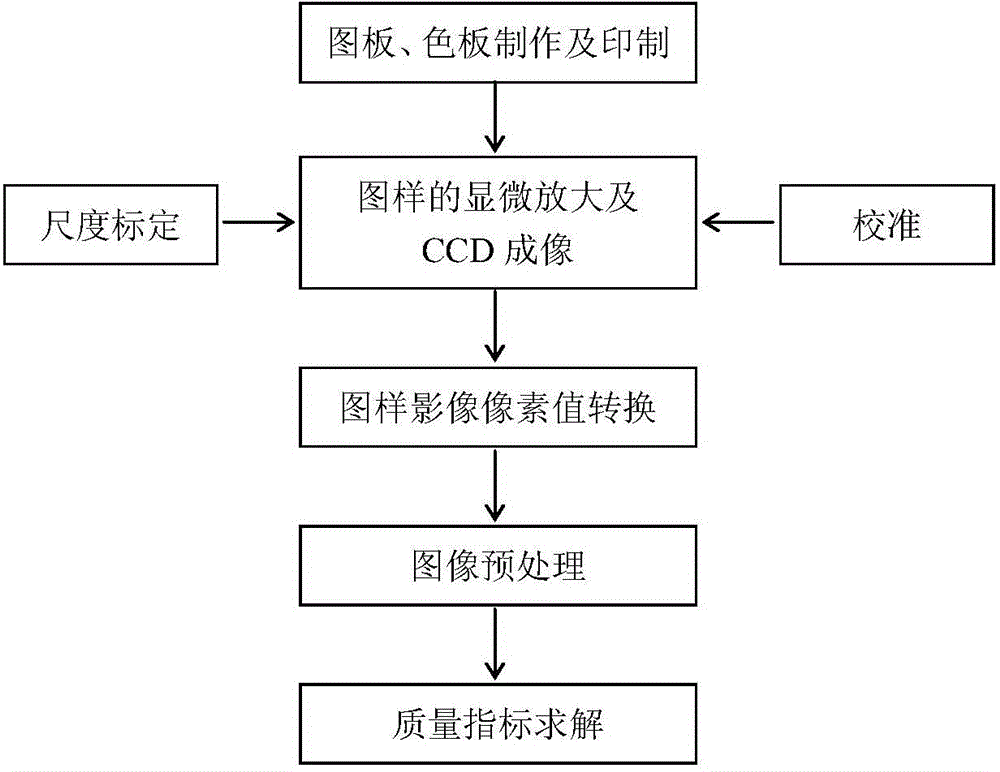

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and examples, but they cannot be used to limit the scope of the present invention.

[0082] The quality of inkjet printing plate making is closely related to the ink used, substrate, and printing control process parameters. This embodiment describes the microscopic quality inspection process of the printing plate imaged by the 1800dpi printout.

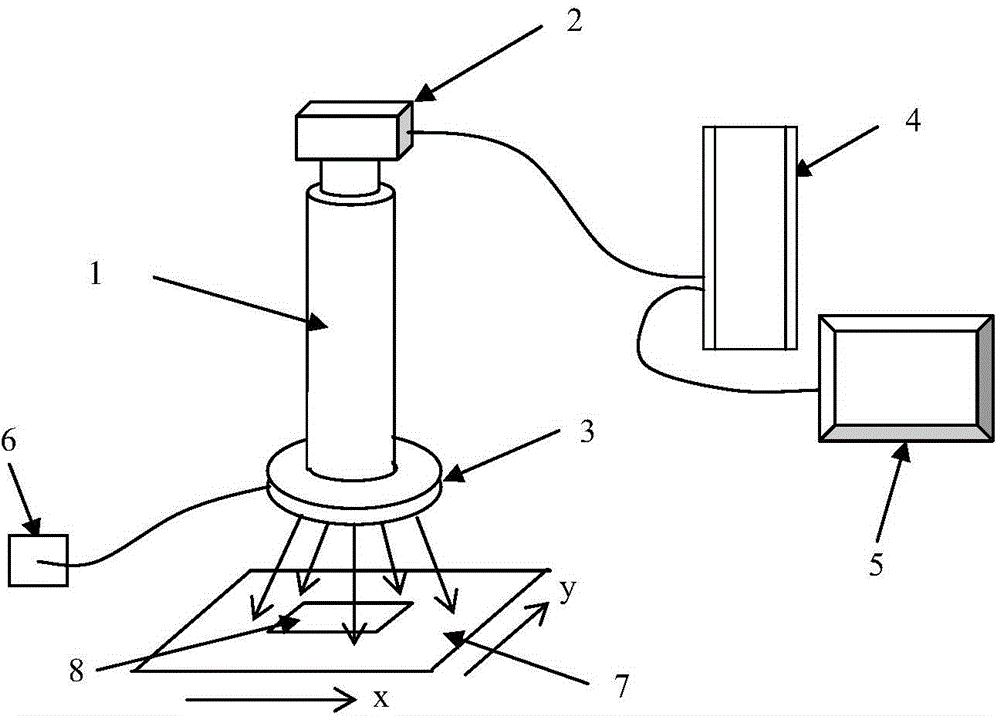

[0083] The detection system used consists of two parts, hardware and software. The hardware includes microscopic magnification optical system, CCD color imaging device and computer, etc.; the software is a calculation tool for image acquisition and various microscopic quality indicators. Such as figure 2 As shown, the test system includes a microscope 1, a CCD imaging device 2, a ring light source 3, a computer 4, a display 5, a power supply 6, an xy mobile storage platform 7, a test sample 8, and the like.

[0084] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com