Fuel battery pack with testing function

A technology for fuel cell stacks and testing functions, which is applied in fuel cell grouping, fuel cells, fuel cell additives, etc., can solve problems such as inability to test and study key materials, and achieve compact structure, easy maintenance, and accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments illustrate the fuel cell stack provided by the present invention in detail with reference to the accompanying drawings.

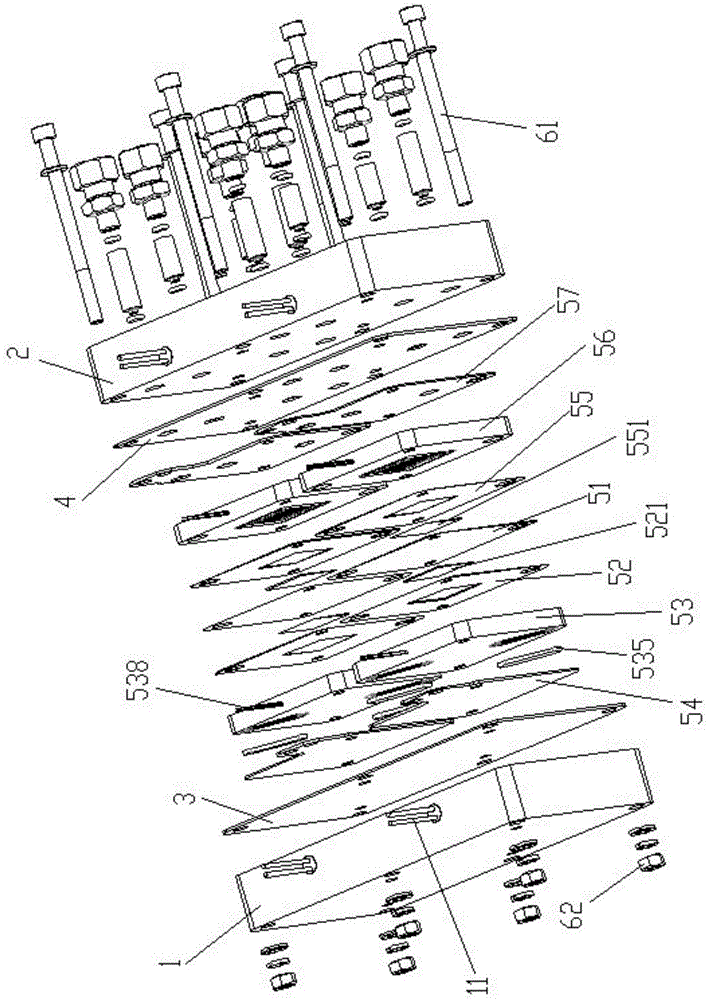

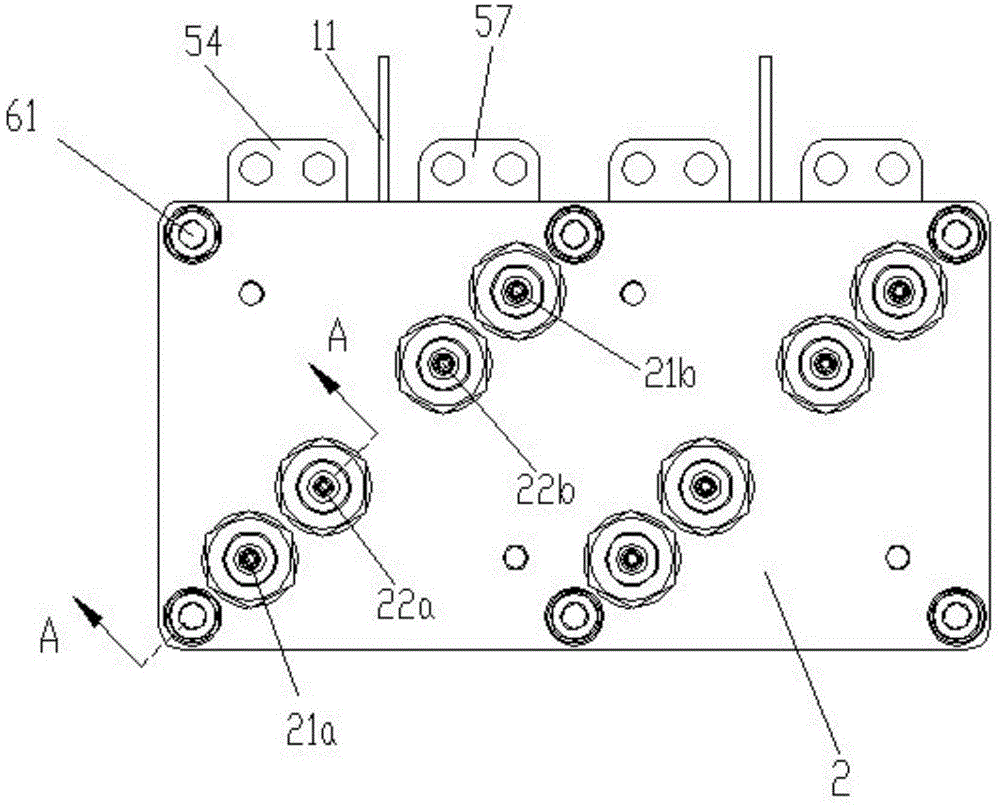

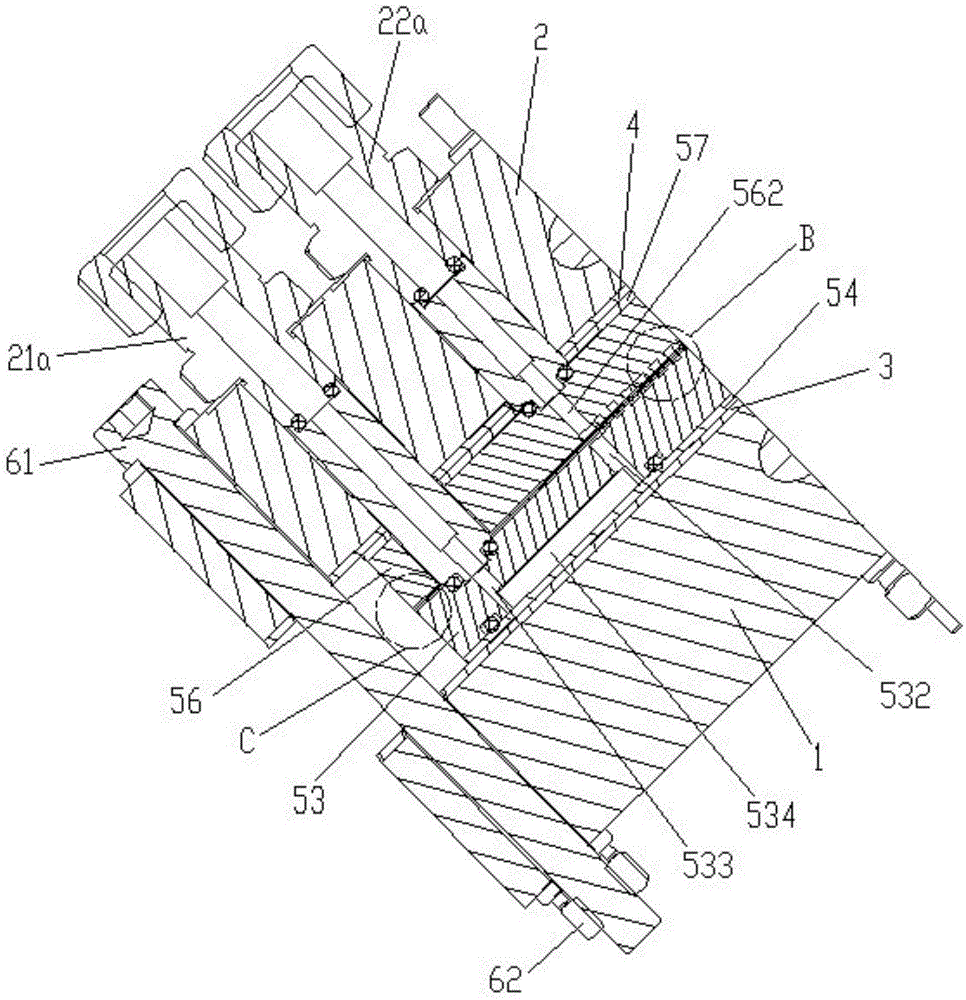

[0030] Such as Figures 1 to 3 As shown, the fuel cell stack provided in this embodiment can be tested for each component material of the fuel cell (such as membrane electrodes, flow guide electrode plates, etc.). The fuel cell stack includes: an anode end plate 1 , a cathode end plate 2 , two mutually independent fuel cells, and several fastening components fastened to connect the anode end plate 1 and the cathode end plate 2 . In this embodiment, the fastening assembly includes: a bolt 61 passing through the anode end plate 1 and the cathode end plate 2 , and a nut 62 screwed with the bolt 61 .

[0031] In order to test the influence of the temperature environment on the material properties of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com