Fluid container, in particular hydraulic reservoir for a motor-pump unit

A fluid container and pump unit technology, applied in the field of hydraulic tanks, can solve the problems of reduced working efficiency, mixing of air and hydraulic oil, etc., and achieve the effect of avoiding the formation of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

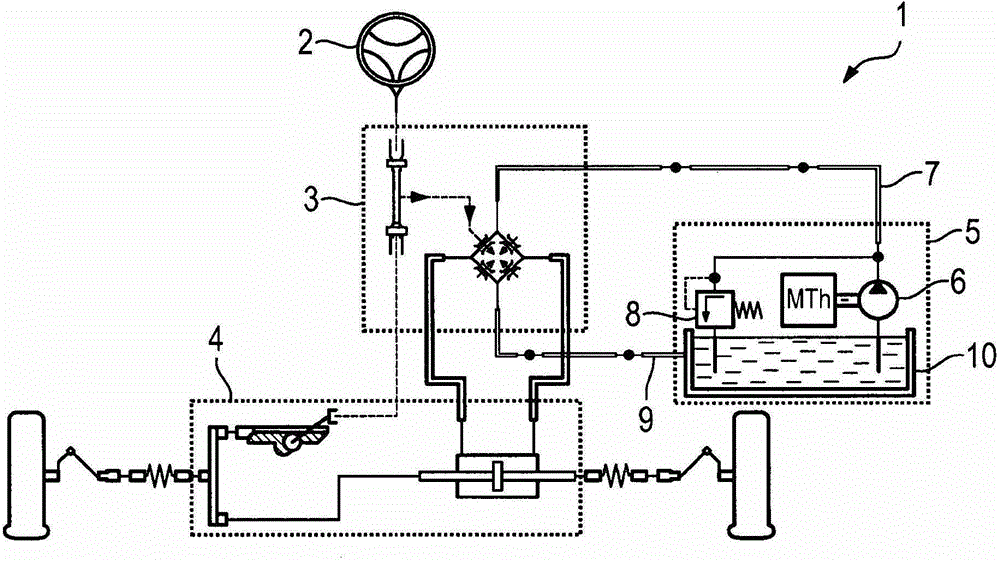

[0025] figure 1 A schematic diagram of an electrohydraulic vehicle steering system 1 is shown, comprising a steering wheel 2 , which is coupled in a known manner to a steering gear 4 via a servo valve 3 . Furthermore, a motor-pump unit 5 is provided which forms the interface between the electric and hydraulic parts of the electrohydraulic vehicle steering system 1 and which comprises a pump 6 which supplies the hydraulic circuit 7 with a supply from a hydraulic tank 10 in a known manner. Hydraulic oil in the form of a fluid container. The pump 6 has a pressure relief valve 8 , through which the fluid flow returns directly from the pressure side of the pump 6 into the hydraulic tank 10 . Furthermore, the hydraulic oil returned by the hydraulic circuit as a return flow 9 is fed to a hydraulic tank 10 .

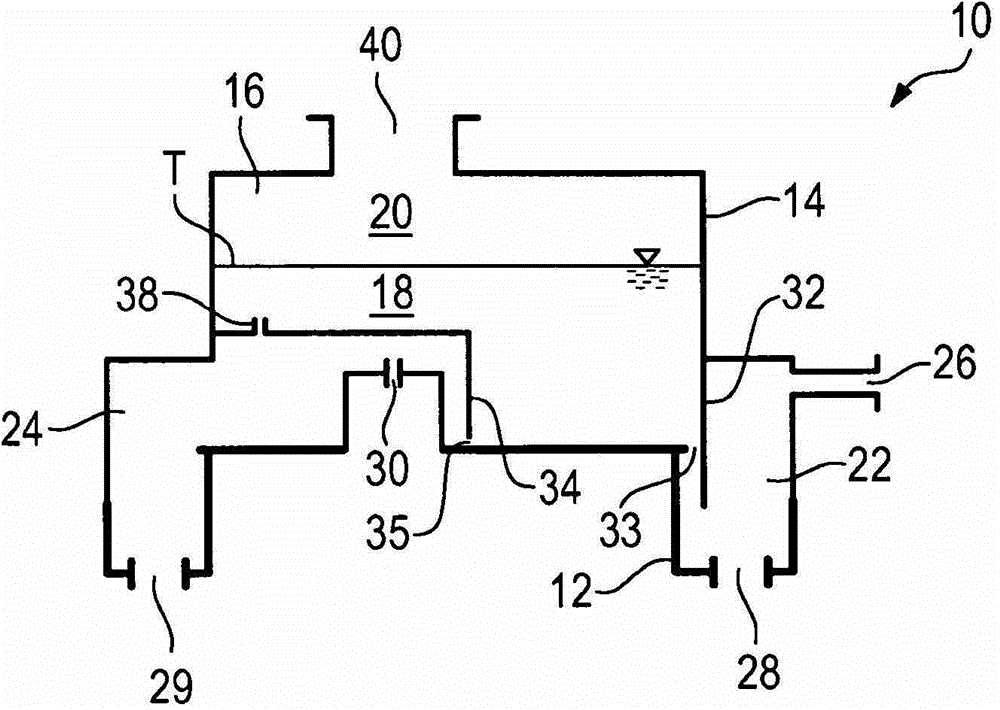

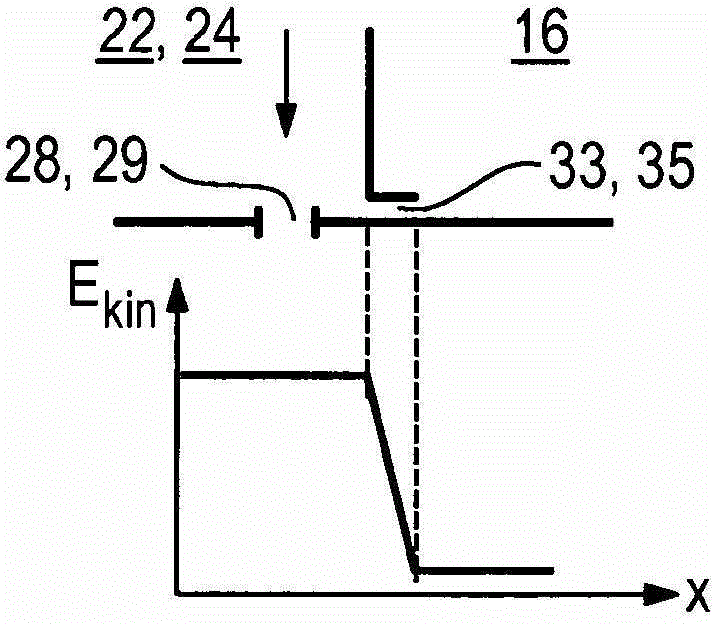

[0026] figure 2 , 4 , 5 and 6 show a first embodiment of a fluid container according to the invention in the form of a hydraulic tank 10 for a motor-pump unit 5 . The hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com