Deep scarification cultivation machine auger bit of preventing soil mounding

A technology of auger bit and cultivator, which is applied in the direction of agricultural machinery and implements, application, plow, etc., can solve the problems of piling up soil and reducing the production efficiency of arable land operations, and achieve the effects of improving production efficiency, simple structure, and eliminating the phenomenon of piling up soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

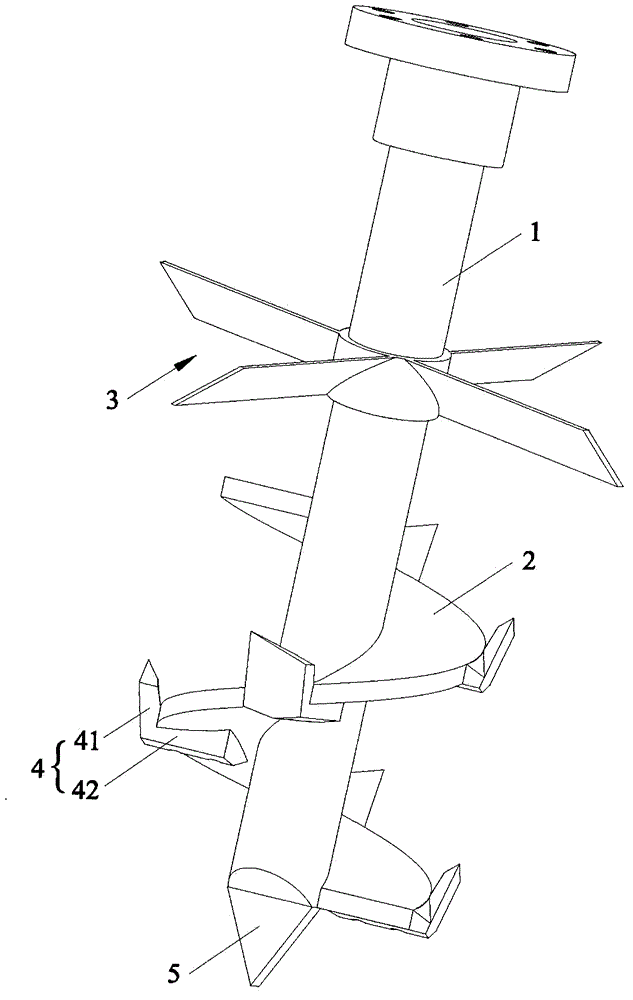

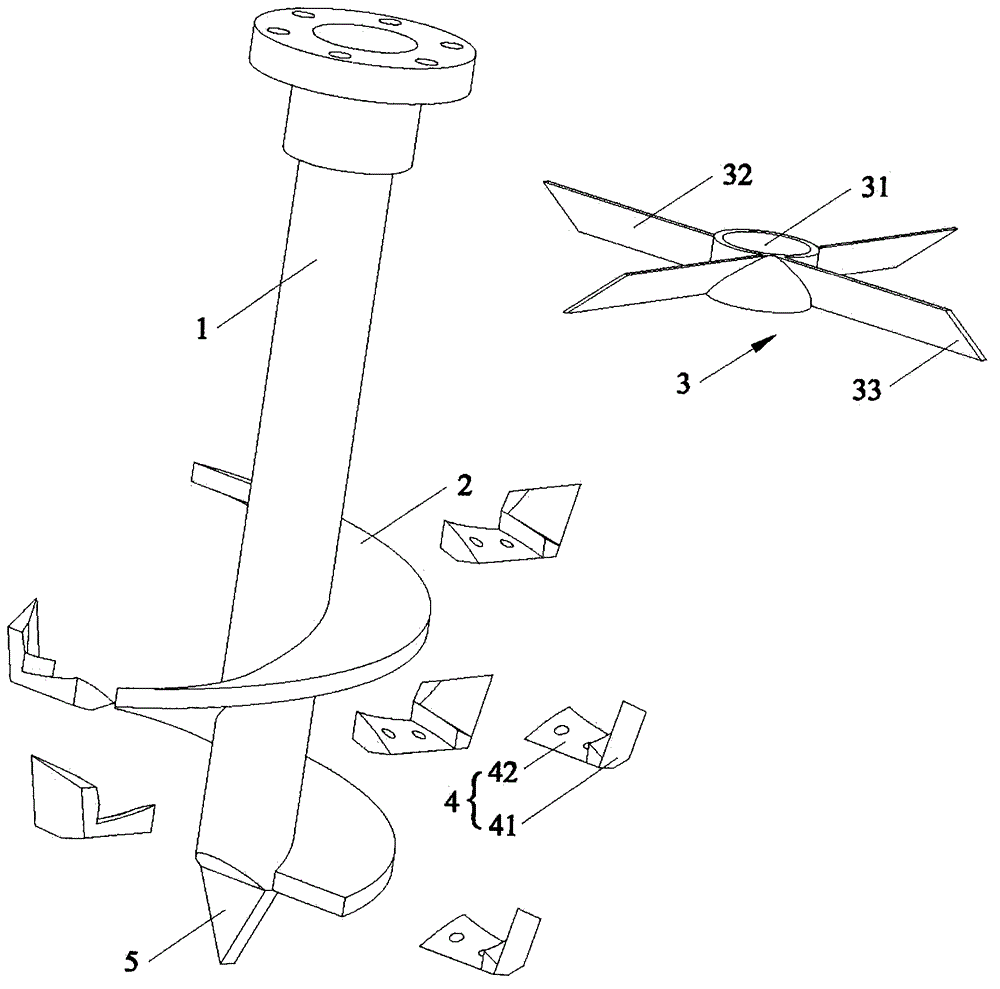

[0022] Such as figure 1 , figure 2 As shown, the direction of this embodiment is figure 1 The placement direction of the auger bit of the subsoil cultivator that avoids piled up soil as shown is as the criterion, and the auger bit of a subsoil tiller that avoids piled up soil in this embodiment includes a drill rod 11, a helical blade 2, and a helical blade 2 is wound around the lower part of the drill rod 1, and it also includes a cross-cutting blade 3, which is arranged on the upper part of the drill rod 1 and above the helical blade 2. The structure of the present invention is simple, because the upper part of the drill pipe 1 is provided with a cross-cutting blade 3, the cross-cutting blade 3 can be connected to the upper half of the drill pipe 1 by welding or fasteners, and the drill pipe 1 rotates while working on the land. As the subsoiling tiller moves forward, the cross-cutting blade 3 can effectively level the piled soil generated in front of the drill pipe 1 afte...

Embodiment 2

[0028] The difference between this embodiment and the first embodiment is that in this embodiment, the auger bit further includes a soil cutting blade 4 , which is arranged on the peripheral edge of the helical blade 2 . When using the auger bit of the present invention to plow the land, the helical blade 2 rotates to ridge up the soil, and the soil cutting blade 4 can assist the helical blade 2 to cut, rub and pulverize the soil that is automatically ridged upward by the action of the helical blade 2, greatly The efficiency of cutting the soil layer of the auger bit and the working efficiency of the subsoiler are improved, and it is also beneficial to store more air inside the soil.

[0029] In this embodiment, there are at least two soil cutting blades 4 , and at least two soil cutting blades 4 are arranged at intervals along the helical direction of the helical blade 2 . The more the number of soil cutting blades 4 is, the more beneficial the auxiliary helical blades 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com