Double-rotation type agitation device

A stirring device, rotary technology, applied in the direction of mixer accessories, dissolving, mixer, etc., can solve the problems of poor mixing effect, high energy consumption of the mixer, long mixing time, etc., achieve shortened mixing time, simple structure, and improved mixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

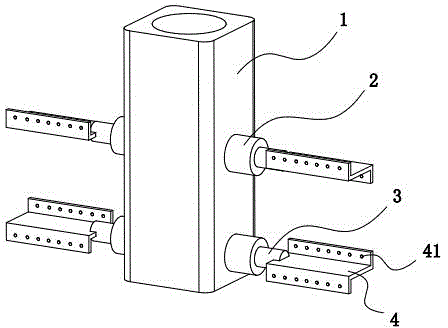

[0012] See figure 1 , the present invention comprises stirring shaft 1, the section of stirring shaft 1 is a square structure, both sides of stirring shaft 1 are symmetrically fixed to cylindrical seat 2 arranged up and down, and cylindrical seat 2 is respectively rotated and connected to rotating shaft 3, and the end of rotating shaft 3 is fixed Connected to the stirring blade 4, in order to facilitate the rotation of the stirring blade 4 around the shaft, the cross section of the stirring blade 4 is arranged in a Z-shaped structure. In order to reduce the resistance between the stirring blade 4 and the resin, a plurality of through holes 41 are arranged on the stirring blade 4.

[0013] In the present invention, since the connecting plate 3 is arranged obliquely, the stirring blade 6 forms a stepped structure, which realizes simultaneous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com