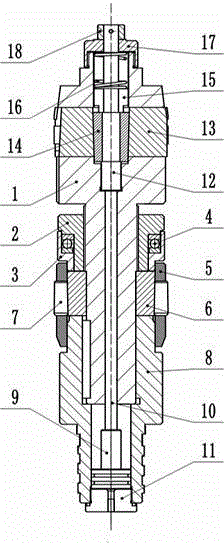

Deep hole automatic boring head

A boring head, automatic technology, applied in the direction of boring head, etc., can solve the problems of difficult matching of workpieces, high production cost, boring head without precision tool adjustment system, etc., and achieve the effect of simplifying the operation process and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

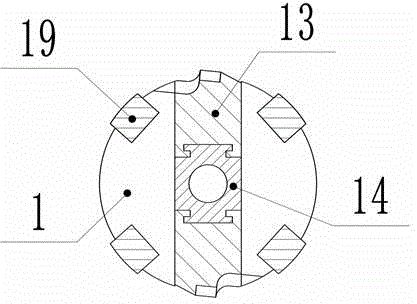

[0014] This tool works by advancing boring, pulling back and rolling. Rotate the adjusting nut 17 to drive the forward and backward tool rod 12 and the forward and backward tool cone 14 to move forward and backward. When the forward and backward tool cone 14 moves forward, the tool holder 13 is retracted inward due to the backward taper of the forward and backward tool cone 14. The processing size is reduced. On the contrary, the processing size is enlarged. As a result, precise tool adjustment is achieved. Rotate the rolling adjusting nut 2 to move the position of the pressure bearing 4 back and forth. When it moves forward, the retainer 5 also moves forward, because the raceway 6 tapers backward, the roller 7 expands outward, and the machining size increases. On the contrary, the processing size is reduced.

[0015] in working, First adjust the rotating diameter of the boring tool tip. The final position of the roller 7 after it is opened to meet the processing requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com