Light guide plate scribing machine and cutting die device thereof

A technology of light guide plate and cutting die, which is applied in metal processing and other directions, can solve the problems of difficulty in achieving uniformity and depth of scribing lines, high power consumption, and low efficiency, so as to reduce equipment costs and processing power consumption, and improve Processing efficiency, consistent depth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

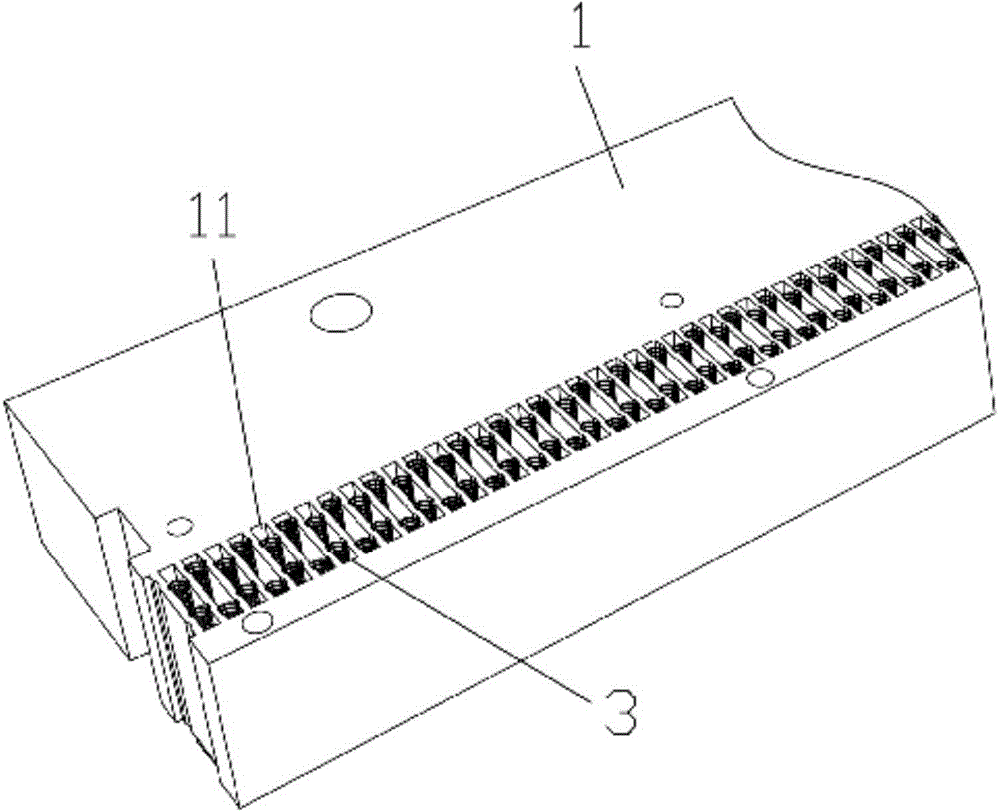

[0019] The utility model relates to a light guide plate marking machine, which is used to carry out network dot marking on the light guide plate, and includes a numerical control device, a moving shaft and a cutting die device.

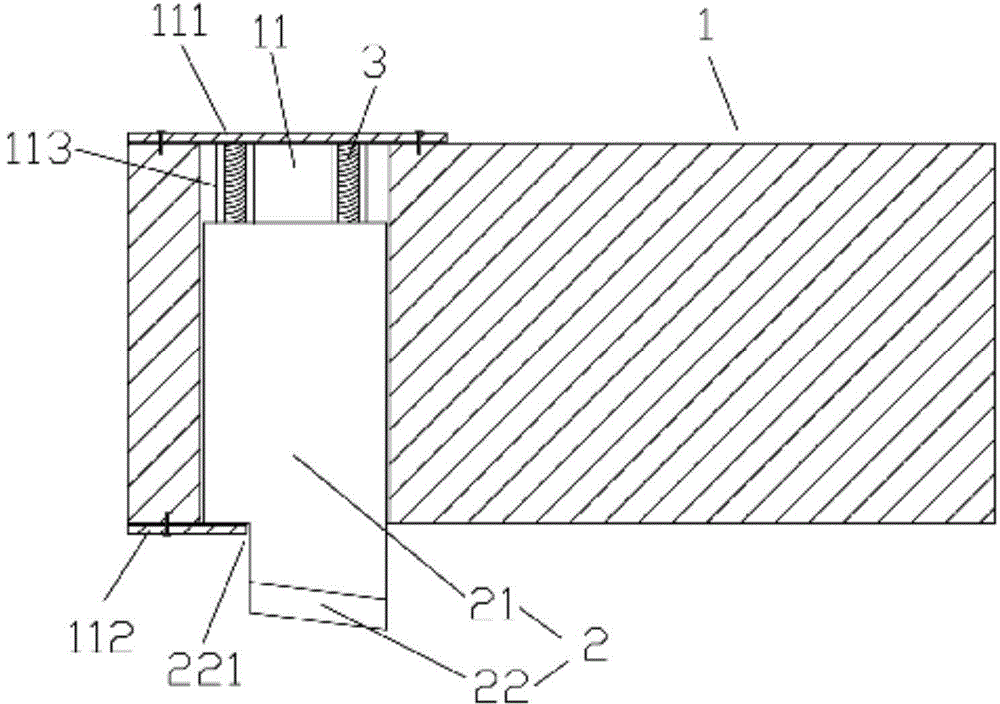

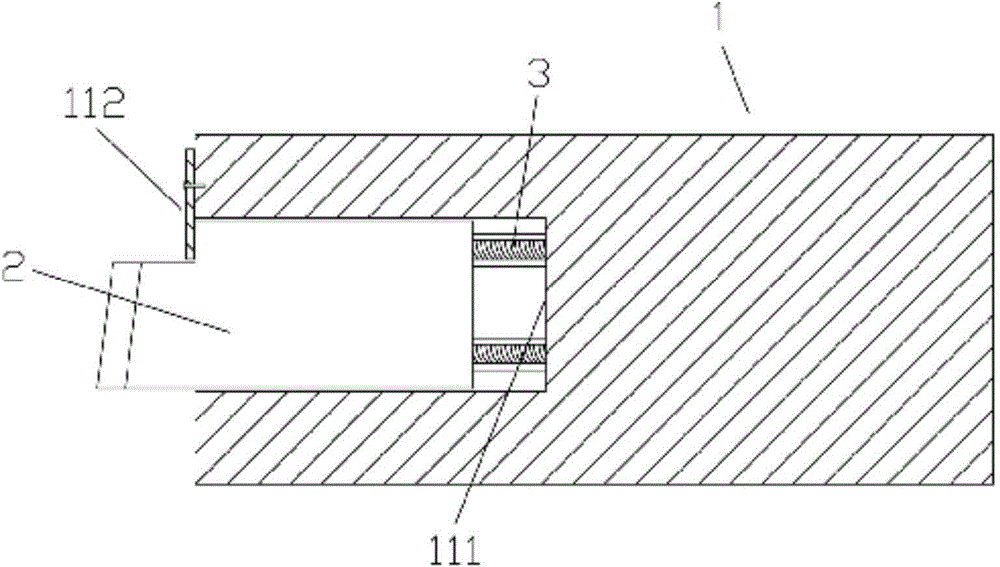

[0020] refer to Figure 1 to Figure 3 , The knife mold device includes a knife mold body 1 , a blade 2 , and an elastic member 3 .

[0021] There are several sipes 11 arranged side by side on the die die body 1, one end of the sipes 11 is a limiter 111, and a stopper 112 is also provided on the sipes 11; two kinds of sipes 11 are provided. In a preferred manner, when the sipes 11 are vertically penetratingly arranged on the die die body 1 , the limiting end 111 of the sipes 11 is a limit top plate fixed on the top surface of the die die body 1 ; When the knife groove 11 is arranged laterally on the knife mold body 1 , the limiting end 111 of the knife groove 11 is a closed end.

[0022] The blade 2 includes a blade body 21 and a knife edge 22 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com