Vertical box packing machine

A cartoning machine, vertical technology, used in packaging, packaging protection, transportation and packaging, etc., can solve problems affecting product quality, product container surface scratches, etc., achieve a high degree of automation, reduce labor costs, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

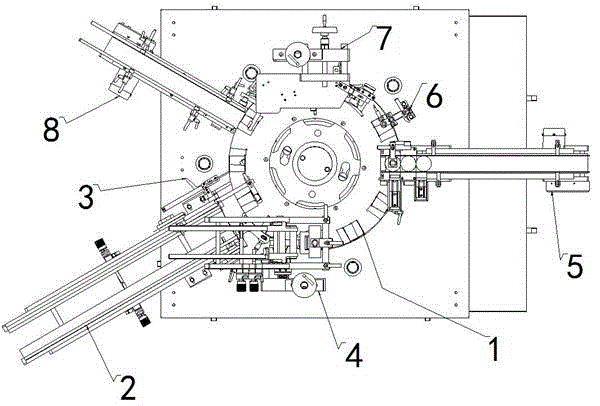

[0035] Such as figure 1 As shown, the vertical cartoning machine includes a rotary station 1 and a box feeding mechanism 2 arranged around the rotary station, a box opening mechanism 3, a paper insertion mechanism 4, a feeding mechanism 5, a pressing mechanism 6, and a closing mechanism. Box mechanism 7, finished product conveying mechanism 8, said station table 1 evenly distributes a number of stations, said box feeding mechanism 2, box opening mechanism 3, paper insertion mechanism 4, feeding mechanism 5, pressing mechanism 6, box closing The mechanism 7 and the finished product conveying mechanism 8 are set corresponding to the stations in turn.

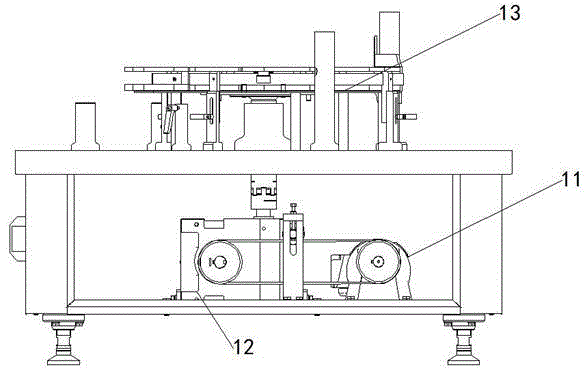

[0036] Such as figure 2 As shown, the rotary station includes a motor 11, a reducer, an angle encoder, a cam divider 12, and a station turntable 13, the motor 11 is connected to the reducer, and the re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap