Multifunctional and energy-saving heave compensation drawworks for ultra-deep floating drilling and its working method

A heave compensation, multi-functional technology, applied in hoisting device, mechanical equipment, spring mechanism, etc., can solve the problems of small transformation range, large volume, small flow, etc., to achieve heave compensation, save the Heave compensation system, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

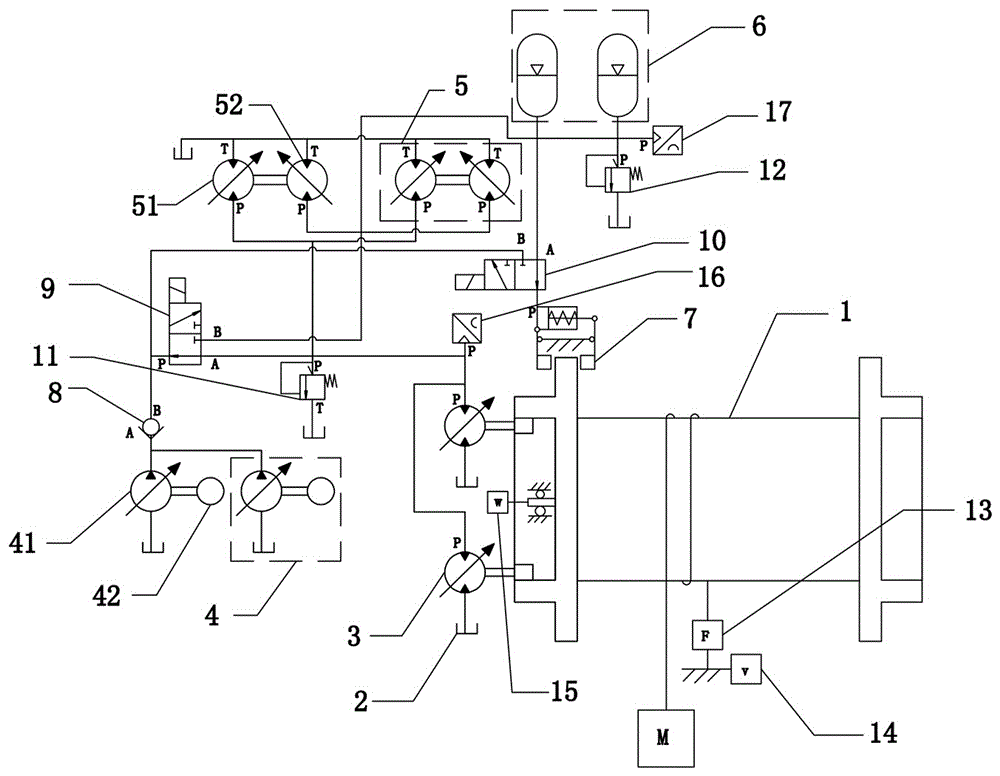

[0021] Such as figure 1 As shown, the winch of this embodiment includes a drum 1, two drum hydraulic motors 3, a speed reduction mechanism, two direct drive pump source mechanisms 4, two hydraulic transformers 5, an accumulator group 6, a hydraulic brake mechanism 7, Pump source safety valve 11, accumulator group safety valve 12, check valve 8, pump source reversing valve 9, brake reversing valve 10 and oil tank 2.

[0022] Wherein, a steel wire rope is wound on the drum 1, one end of the steel wire rope is hung with a suspended object, and the other end is a dead rope end fixedly connected with the platform, and the drum 1 rotates in different directions to realize the lifting of the suspended object. In this embodiment, an internal gear is provided on one side of the drum 1, and the output shafts of the two drum hydraulic motors 3 are connected to the input end of the deceleration mechanism, and the output gear of the deceleration mechanism meshes with the internal gear of t...

Embodiment 2

[0043] Such as image 3 As shown, in this embodiment, internal gears are provided on both sides of the drum 1 of the winch, and the winch is divided into symmetrical left and right sides with the drum 1 as the center, and the structure of each side is the same as that of Embodiment 1. , and the control systems on both sides jointly control the drum 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com