Ship crane heave compensation system, compensation method and operation method

A marine crane and heave compensation technology, which is applied in the direction of cranes, spring mechanisms, load suspension components, etc., can solve the problems of marine crane heave compensation lag, high cost, low compensation accuracy, etc., to achieve strong adaptability, The effect of low cost and accurate heave compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

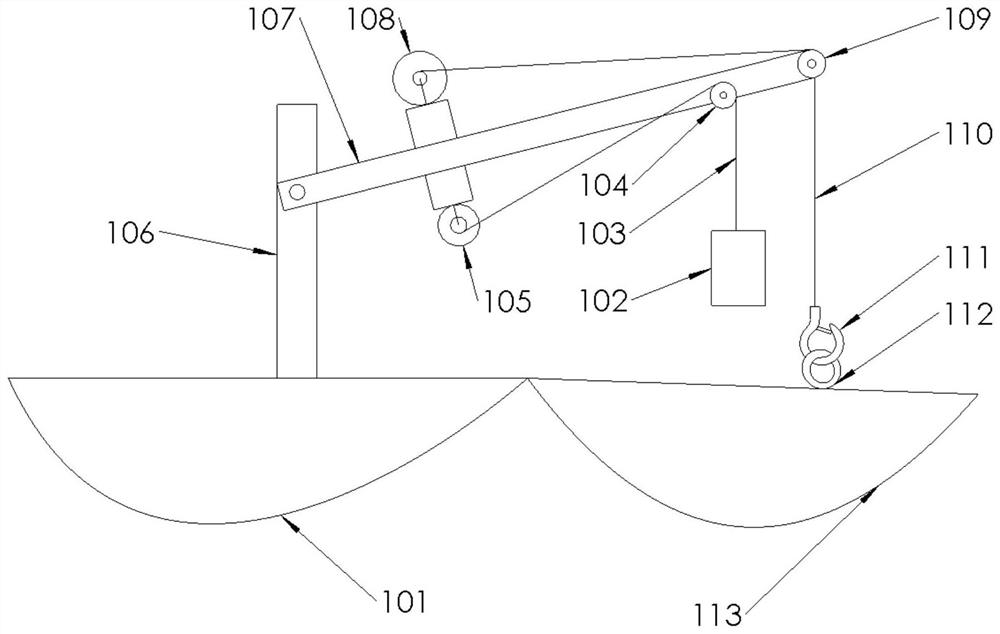

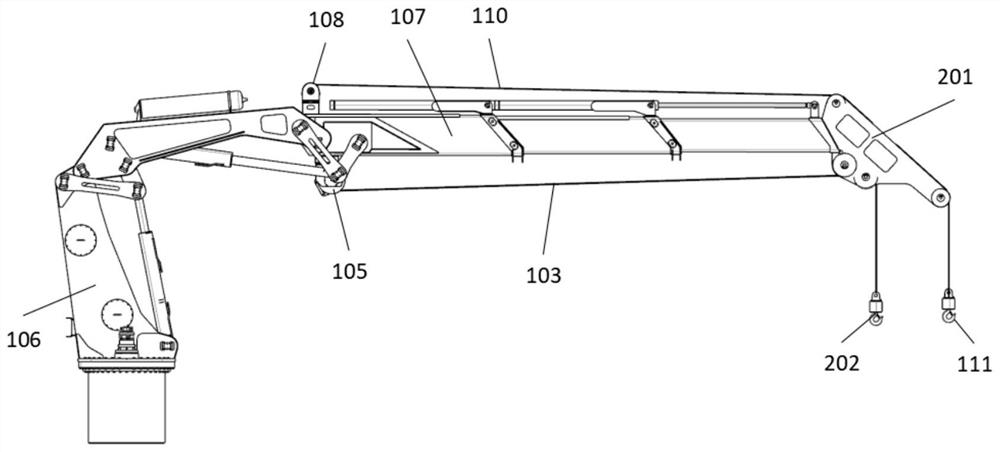

[0036] Such as Figure 1 to Figure 4 As shown, the present invention includes a supply ship 101 and a supplied ship 113. A crane base 106 is installed on the deck of the supply ship 101. The crane can realize a larger operating range, facilitate the completion of cargo replenishment between ships, and save the supply ship 101' of deck area. A boom 107 is installed on the base 106, and the boom 107 is rotatably connected with the base 106 by a hinge, and the other end of the boom 107 is equipped with a crane head 201, such as figure 2 As shown, the first guide wheel 104 and the second guide wheel 109 are installed on the crane head 201 .

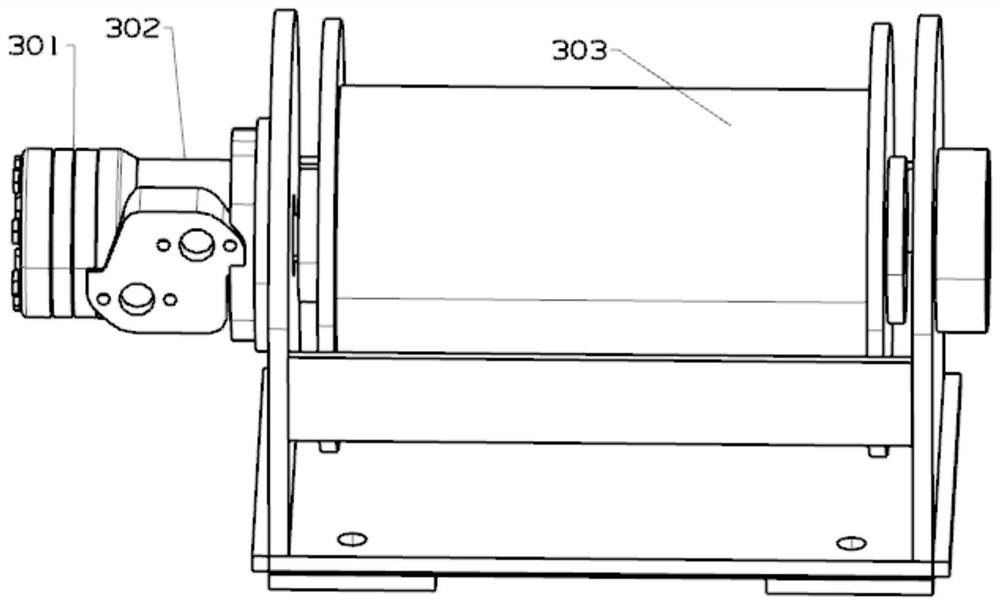

[0037] Such as figure 1 As shown, a measuring winch 108 is installed on one side of the boom 107, and a compensation winch 105 is installed on the other side, as image 3 As shown, the measuring winch 108 includes an encoder 301, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com