A heat-resistant sphere and its production process

A production process and technology for spheres, applied in the field of heat-resistant spheres and their production processes, can solve the problems of affecting service life and safety, large cold cracking tendency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

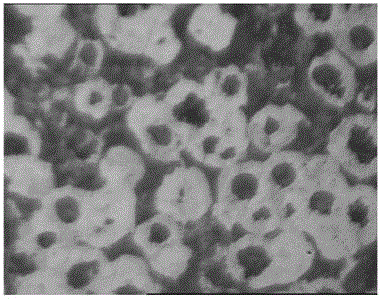

Image

Examples

Embodiment 1

[0042] A heat-resistant sphere, the components of the heat-resistant sphere are as follows in terms of mass percentage: C 3.00%, Si 1.8%, Mn 0.2%, Ni 2.0%, Mo 0.3%, P 0.07%, S 0.02%, remainder The main content is Fe. By adding Ni and a small amount of Mo alloy in the composition, we increase the toughness and high temperature resistance of the material, ensure the thermal fatigue resistance of the material, prevent the tendency of cracking, improve the safety factor and prolong the service life.

[0043] A process for producing the heat-resistant sphere as claimed in claim 1, comprising the following steps:

[0044] Step 1 charge: nodular pig iron Q10, nickel plate, ferromolybdenum, steel scrap, low S content in the molten iron is ensured in the charge, industrial soda ash is used to remove S in the bag, and the sulfur S content in the molten iron can be reduced by using this method to remove S Reduced to 0.02%, good nodularization.

[0045] Step 2 Feeding: Add the ingredient...

Embodiment 2

[0054]A heat-resistant sphere, the composition of the heat-resistant sphere is as follows in terms of mass percentage: C 4.20%, Si 3.0%, Mn 1.2%, Ni 4.0%, Mo 1.0%, P 0.06%, S 0.01%, remainder The main content is Fe. By adding Ni and a small amount of Mo alloy in the composition, we increase the toughness and high temperature resistance of the material, ensure the thermal fatigue resistance of the material, prevent the tendency of cracking, improve the safety factor and prolong the service life.

[0055] A process for producing the heat-resistant sphere as claimed in claim 1, comprising the following steps:

[0056] Step 1 charge: nodular pig iron Q10, nickel plate, ferromolybdenum, steel scrap, low S content in the molten iron is ensured in the charge, industrial soda ash is used to remove S in the bag, and the sulfur S content in the molten iron can be reduced by using this method to remove S Reduced to 0.01%, good spheroidization;

[0057] Step 2 Feeding: Add the ingredient...

Embodiment 3

[0066] A heat-resistant sphere, the composition of the heat-resistant sphere is as follows in terms of mass percentage: C 3.6%, Si 2.6%, Mn 0.6%, Ni 3.5%, Mo 0.5%, P 0.03%, S 0.01%, remainder The main content is Fe. By adding Ni and a small amount of Mo alloy in the composition, we increase the toughness and high temperature resistance of the material, ensure the thermal fatigue resistance of the material, prevent the tendency of cracking, improve the safety factor and prolong the service life.

[0067] A process for producing the heat-resistant sphere as claimed in claim 1, comprising the following steps:

[0068] Step 1 charge: nodular pig iron Q10, nickel plate, ferromolybdenum, steel scrap, low S content in the molten iron is ensured in the charge, industrial soda ash is used to remove S in the bag, and the sulfur S content in the molten iron can be reduced by using this method to remove S Reduced to 0.01%, good spheroidization;

[0069] Step 2 Feeding: Add the ingredient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com