Weir pond and pulp fluid box applying same

A headbox and weir pond technology, which is used in textiles and papermaking, papermaking machines, wet parts of paper machines, etc., can solve the problems of affecting the quality of paper products, containing stains in paper towels, and unable to remove the pulp immediately, so as to reduce pollution. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

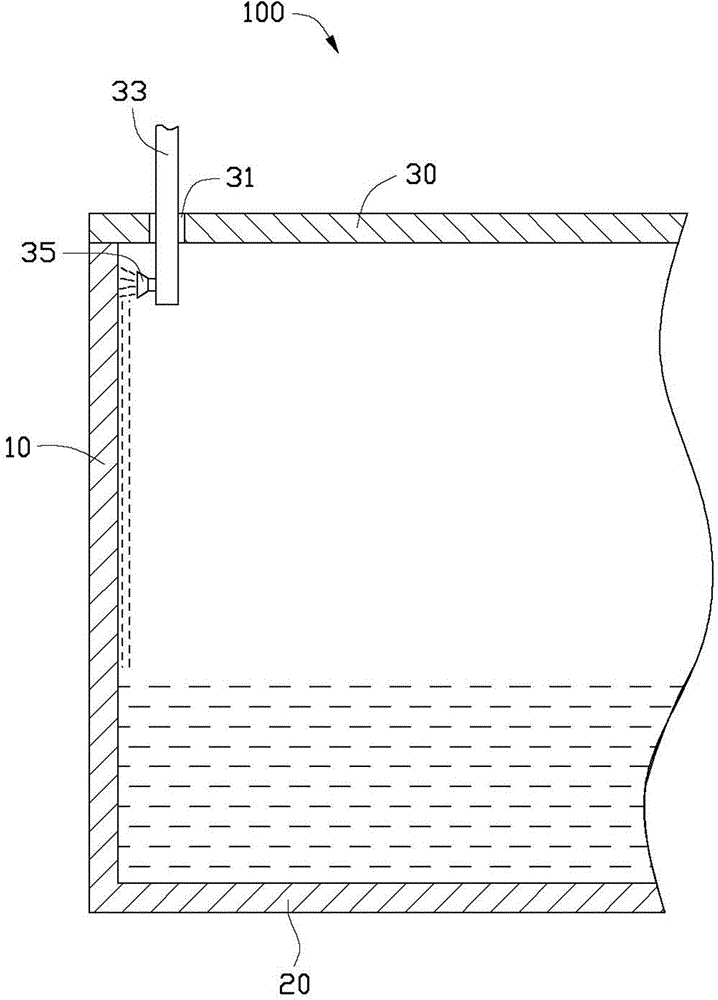

[0014] see figure 1 The weir tank 100 of the headbox in a preferred embodiment of the present invention includes a side wall 10 , a bottom plate 20 and a cover plate 30 , and the side wall 10 , the bottom plate 20 and the cover plate 30 form an accommodating space for accommodating slurry. In this embodiment, the weir tank 100 of the headbox has a plurality of side walls 10 .

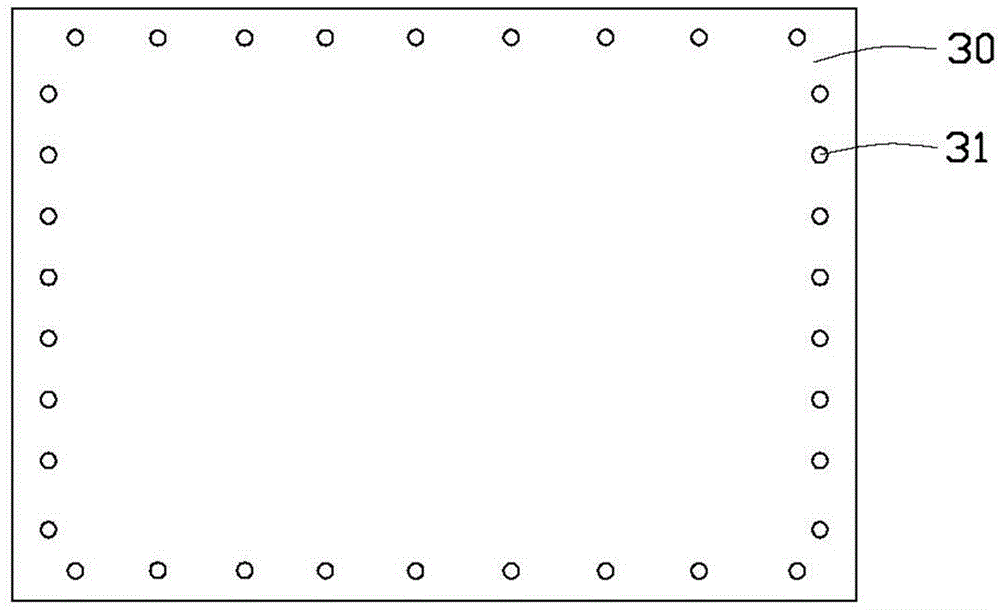

[0015] The cover plate 30 is provided with at least one through hole 31 , and each through hole 31 is pierced with a pipe 33 extending from the outside of the weir pond 100 to the inside of the weir pond 100 . The pipe 33 is connected with a liquid storage device (not shown) at the outer end of the weir pool 100 , and is connected with the nozzle 35 at the inner end of the weir pool 100 . The spray head 35 can spray liquid to the side wall 10 of the weir pool 100 to remove the slurry adhering to the side wall 10 .

[0016] The at least one through hole 31 can be disposed on an edge of the cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com