Chimney glass fiber reinforced plastic inner tube fast installation method

An installation method and glass fiber reinforced plastic technology, applied in building types, buildings, towers, etc., can solve the problems of inability to meet industrial needs, long operation time, and high transportation costs, and achieve the effect of convenient transportation management, reduced engineering time, and reduced installation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

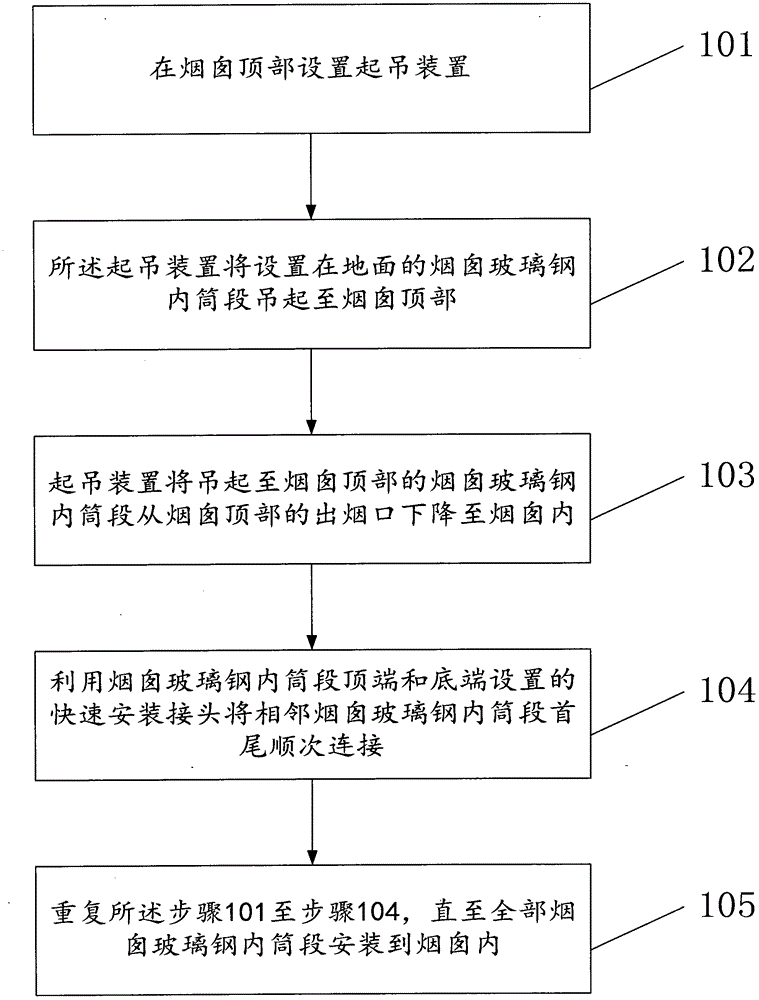

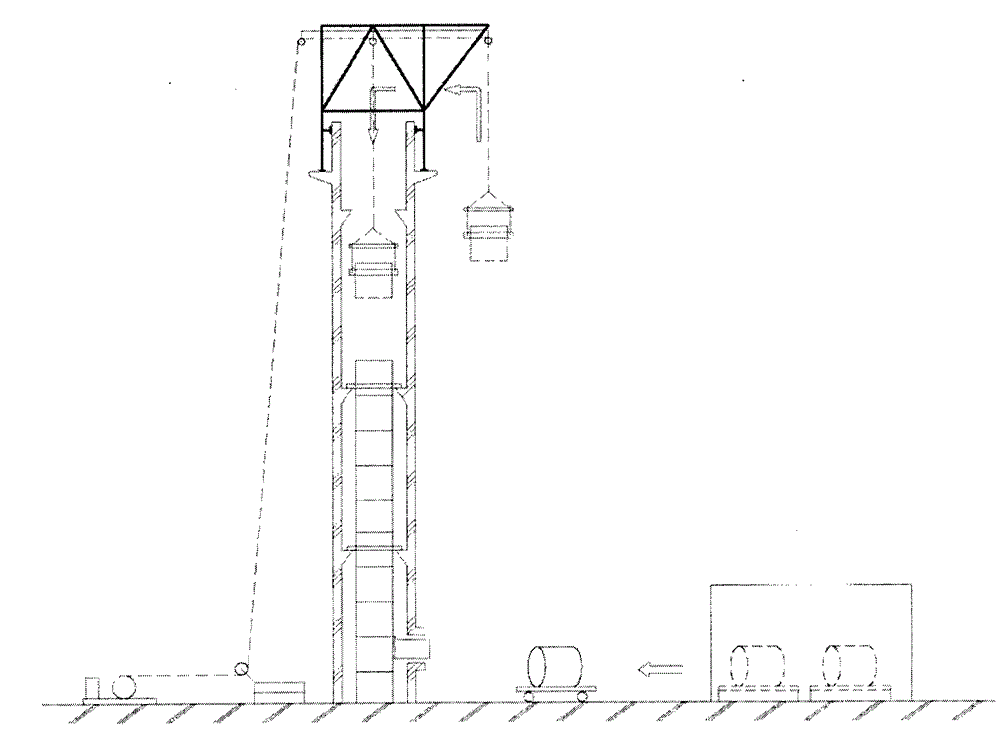

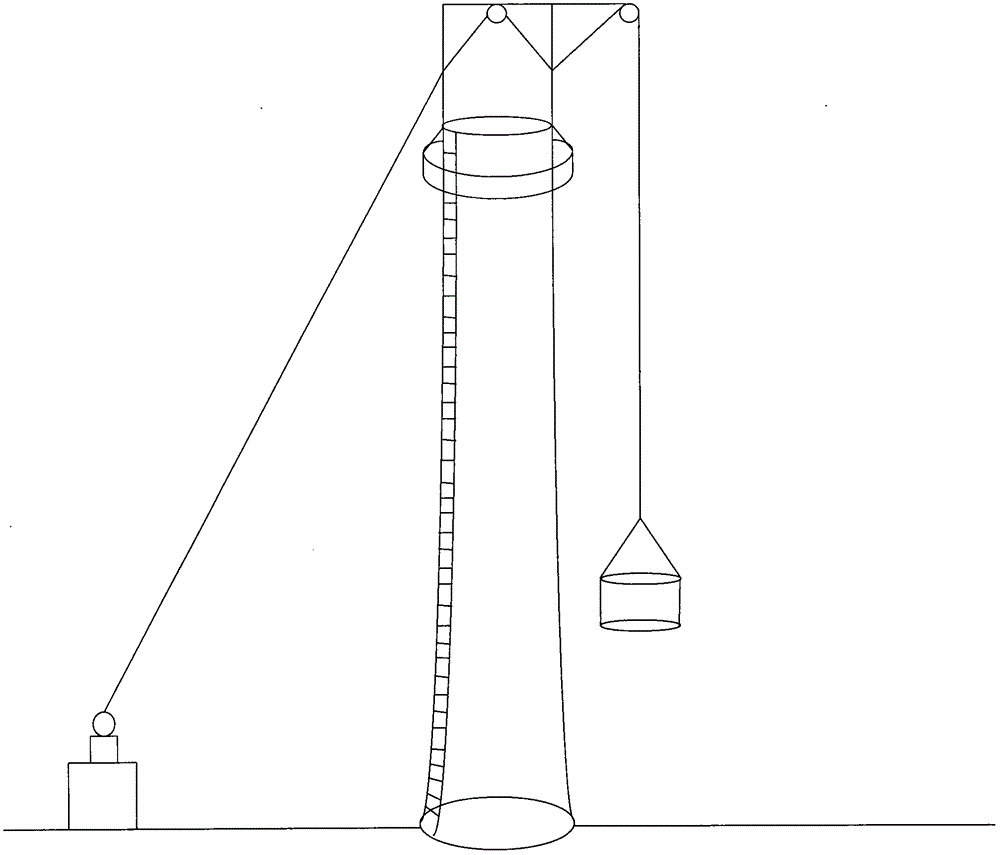

[0042] Such as figure 1 and figure 2 Shown, embodiment of the present invention chimney glass fiber reinforced plastics inner tube fast installation method, described method comprises:

[0043] Step 101: Set up a lifting device on the top of the chimney.

[0044] Step 102: The lifting device lifts the chimney fiberglass inner cylinder section set on the ground to the top of the chimney.

[0045] Step 103: The lifting device lowers the fiberglass inner cylinder section of the chimney lifted to the top of the chimney into the chimney from the smoke outlet at the top of the chimney.

[0046] Step 104: Using the quick installation joints provided at the top and bottom of the chimney glass fiber reinforced plastic inner tube section to connect the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com