Magnetic fluid modular mechanical gripper and working method thereof

A mechanical gripper, magnetic fluid technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problem that the rack and pinion mechanism occupies a large space, the worm gear and worm mechanism have low mechanical efficiency, and is not suitable for heavy-load mechanical work, etc. problems, to achieve the effect of easy disassembly and assembly, easy transportation management, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

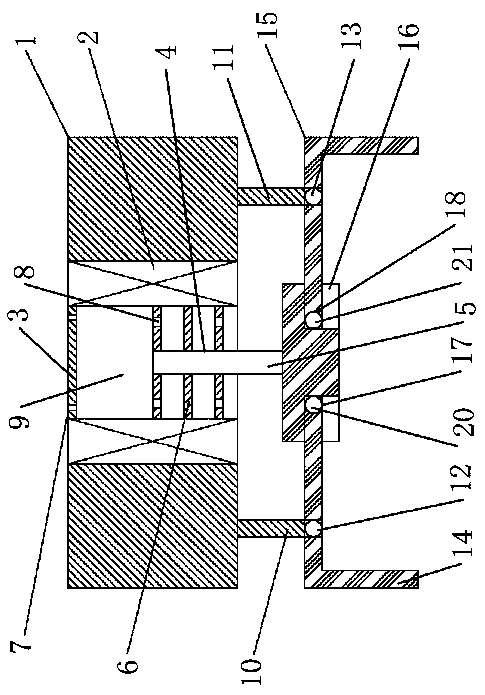

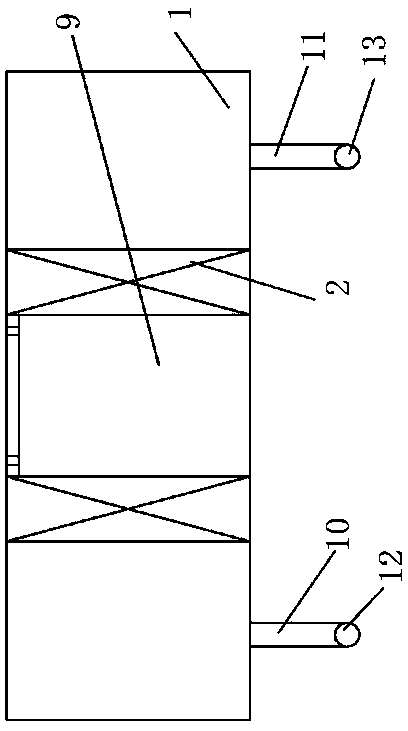

[0024] A magnetic fluid modular mechanical gripper, which consists of: a housing 1, the housing has a cylindrical cavity 9, a magnetic fluid is provided in the cylindrical cavity, and a top baffle is arranged in the cylindrical cavity 3 and a thin baffle plate 6, the thin baffle plate has a central hole 4, the central holes are connected by a vertical rod 5, and the top baffle plate has a group of ventilation holes 7 around the circumference. The thin baffle is provided with a group of liquid holes 8 around the circumference, and coils 2 are installed on both sides of the cylindrical cavity, and the coils are connected to the controller.

Embodiment 2

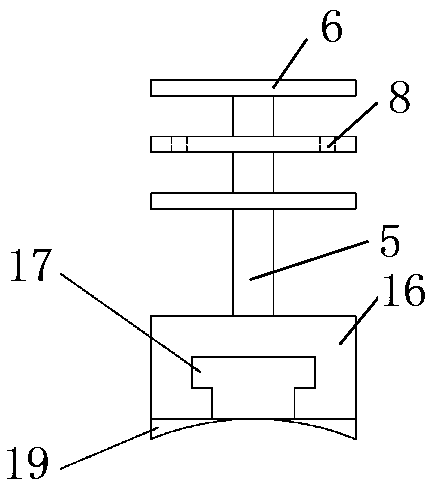

[0026] A magnetic fluid modular mechanical gripper described in Embodiment 1, the bottom of the housing is connected to the left straight rod 10 and the right straight rod 11, the left straight rod is connected to the left circular tube 12, and the right The straight rod is connected to the right circular pipe 13, the left circular pipe is hinged to the left actuator rod 14, the right circular pipe is hinged to the right actuator rod 15, and the left actuator rod and the right actuator rod are simultaneously Connect the lifting mechanism, the lifting mechanism includes the vertical bar, the vertical bar is connected to the rectangular block 16, the rectangular block has a left groove 17 and a right groove 18, the bottom of the rectangular block There is an arched surface 19, and the left groove and the right groove are connected to the arched surface.

Embodiment 3

[0028] In the magnetic fluid modular mechanical gripper described in Embodiment 2, the left actuator rod is connected to the left cylindrical bump 20, the right actuator rod is connected to the right cylindrical bump 21, and the left cylindrical bump 21 is connected to the left cylindrical bump. The block is installed in the left groove, and slides and rotates along the left groove, and the right cylindrical protrusion is installed in the right groove, and moves along the right groove Slide, rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com