Lithium battery inserting plate type management container automatic grading machine

An automatic grading and plug-in technology, which is applied in the field of grading machines, can solve the problems of loss of quality and sales in the application of battery packs, large human factors in grading quality and efficiency, and unsuitability for large-scale production needs, so as to reduce the number of operators, Less motors and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

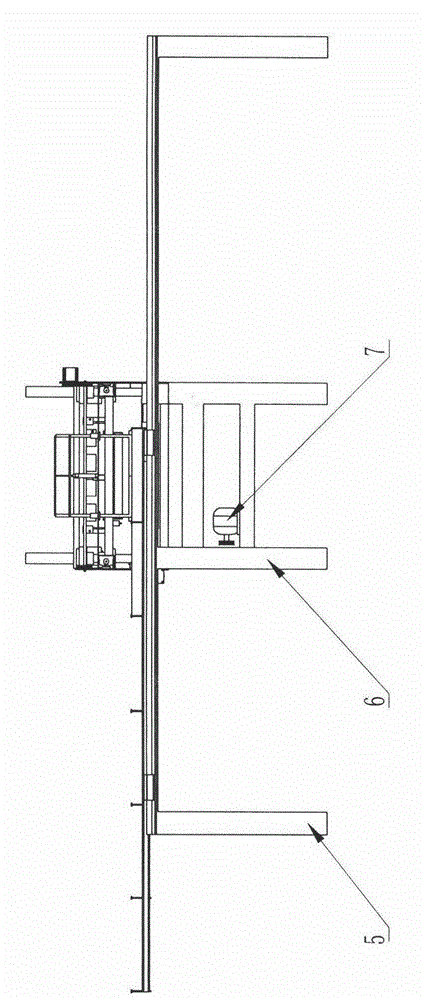

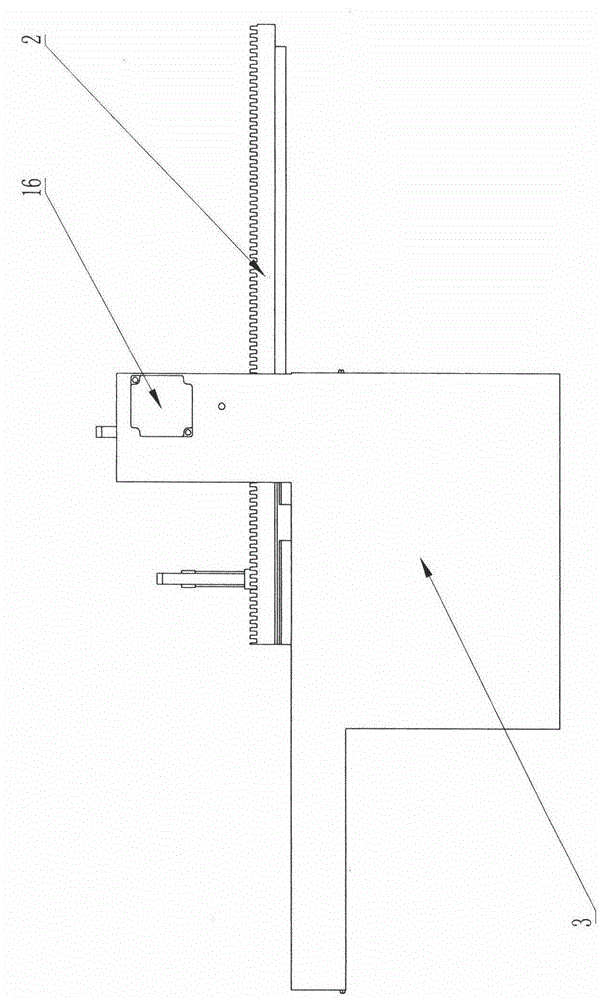

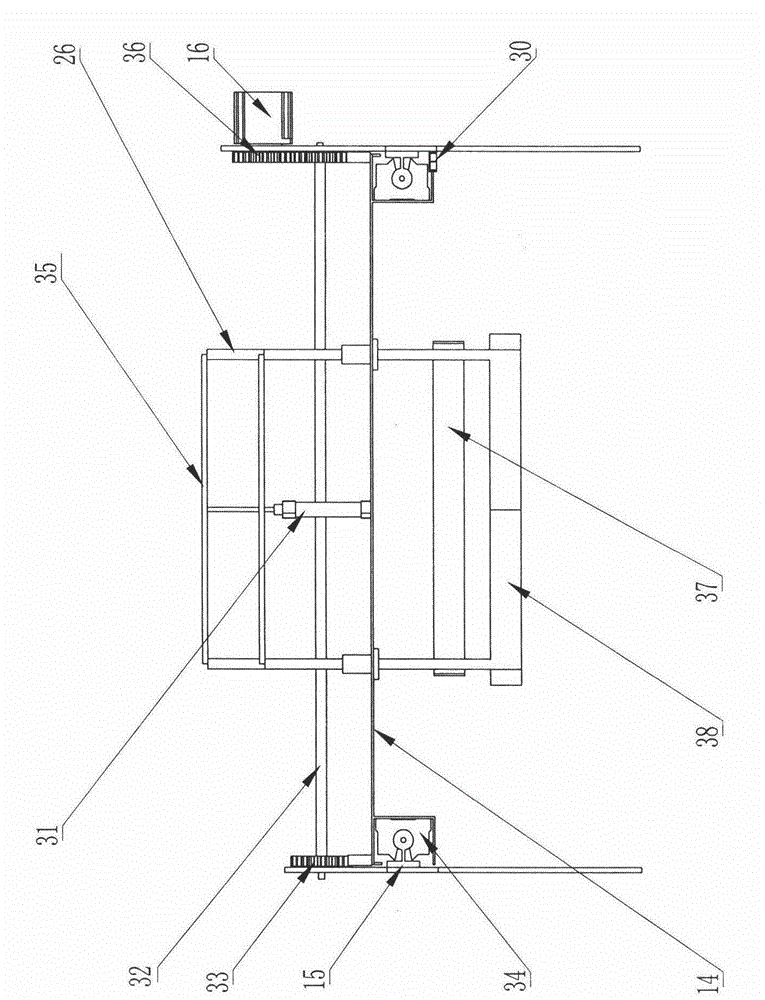

[0042] The present invention is an automatic classification machine for lithium battery plug-in management containers, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12.

[0043] The above N is 2.

[0044] The above-mentioned pulley 22 is a timing pulley.

[0045] The above-mentioned rotating actuator is a rotating electromagnet 10 .

[0046] The above-mentioned lithium battery plug-in type management container includes: a container body 58, a plug-in plate 59 and a pin 60; the container body 58 is a square body, and a point on the top surface of the square body is the coordinate, and the rectangular array has H columns. E, the spacing is C, the number of rows is F, and the spacing is D; on the top surface of the square body, K blocks are respectively raised near any two opposite sides; on the top surface of the square body, there are square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com