Computer control substrate with high-efficiency heat stratification

A technology for controlling substrates and computers, which is applied in the direction of using electric means for temperature control, etc., which can solve the problem that the substrate cannot quickly dissipate heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below by specific embodiment:

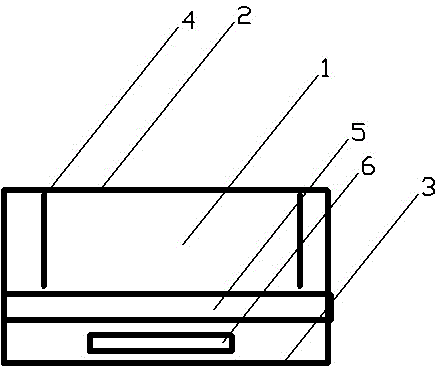

[0010] Such as figure 1 As shown, the thermal stratification high-efficiency computer control substrate includes a silicon material square plate 3 with a top end 1 and a bottom end 2 on the base, and the silicon material square plate 3 contains a metal probe 4 attached to the silicon material square plate 3 in order to construct a magnet. The energy is installed on the partition plate 5 of the silicon material square plate 3 , and an electronic temperature booster 6 is embedded inside the silicon material square plate 3 . The electronic warmer 6 is controlled by an external computer.

[0011] The working principle of the present invention is to confirm that the base has a silicon material square plate 3 with a top end 1 and a bottom end 2. The silicon material square plate 3 contains a metal probe 4 attached to the silicon material square plate 3 in order to construct magnetic energy. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com