Sulfamate water-reducing agent and preparation method thereof

A technology of sulfamic acid salt and sulfamic acid, which is applied in the field of concrete admixture and its preparation, and can solve problems such as easy explosion, hidden safety hazards, and large heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

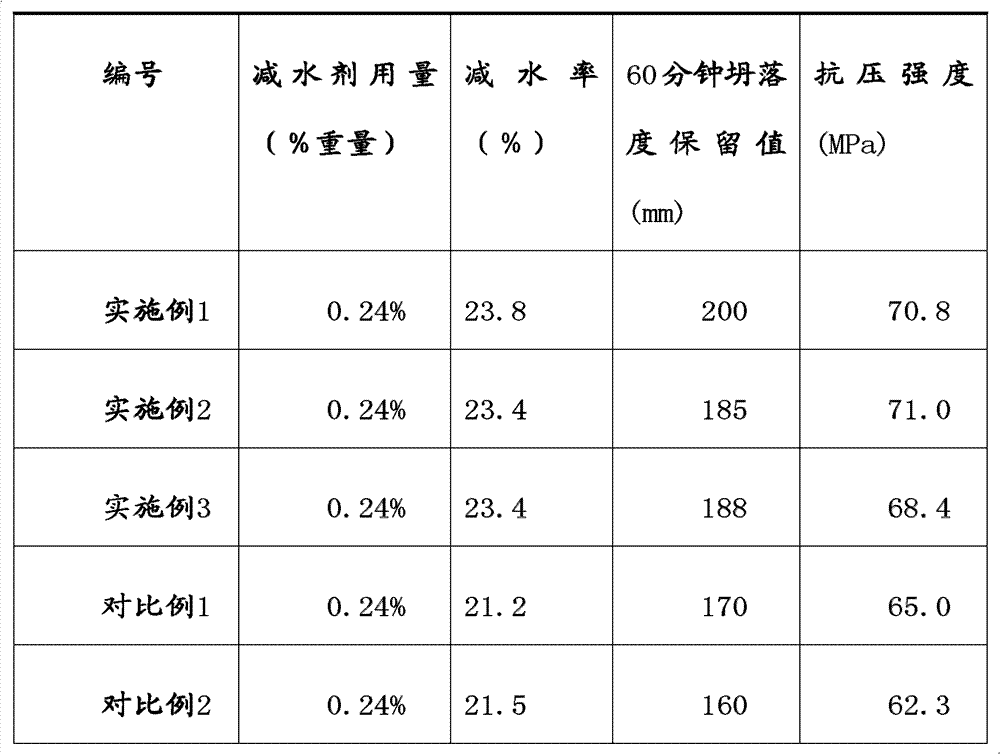

Examples

Embodiment 1

[0013] Add 3000kg of water and about 300Kg of sodium hydroxide into the reaction kettle, stir evenly, add 600Kg of phenol, then continue stirring evenly, add 1050Kg of sulfamic acid, stir for 40 minutes, add 300Kg of formaldehyde dropwise into the reaction system and react for about 1 hour , add 350Kg p-aminobenzenesulfonic acid, then drop 700Kg formaldehyde into the reaction system, continue to react for half an hour, and obtain a liquid product. There is no need to provide external heat during the reaction process, only the heat generated by the reaction is collected and returned to the reactor through the circulation pipeline. It is measured that the molecular weight of the obtained condensation product is about 6000.

Embodiment 2

[0015] Add 3000kg of water and about 300Kg of sodium hydroxide into the reaction kettle, stir evenly, add 600Kg of phenol, then continue stirring evenly, add 1000Kg of sulfamic acid, stir for 40 minutes, add 300Kg of formaldehyde dropwise into the reaction system and react for about 1 hour , add 450Kg p-aminobenzenesulfonic acid, then drop 700Kg formaldehyde into the reaction system, continue to react for half an hour, and obtain a liquid product. There is no need to provide external heat during the reaction process, only the heat generated by the reaction is collected and returned to the reactor through the circulation pipeline. After measurement, the molecular weight of the obtained condensation product is about 6200.

Embodiment 3

[0017] Add 3000kg of water and about 300Kg of sodium hydroxide into the reaction kettle, stir evenly, add 600Kg of phenol, then continue to stir evenly, add 1050Kg of sulfamic acid, stir for 40 minutes, add 350Kg of formaldehyde dropwise into the reaction system and react for about 1 hour , add 350Kg p-aminobenzenesulfonic acid, then drop 600Kg formaldehyde into the reaction system, continue to react for half an hour, and obtain a liquid product. There is no need to provide external heat during the reaction process, only the heat generated by the reaction is collected and returned to the reactor through the circulation pipeline. It is measured that the molecular weight of the obtained condensation product is about 6100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com