High-performance photoelectric composite cable

A photoelectric composite cable, high-performance technology, applied in the direction of insulating cables, communication cables, cables, etc., can solve the problems of poor shielding performance, simple cable structure, unsatisfactory, etc., and achieve the effect of strong shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

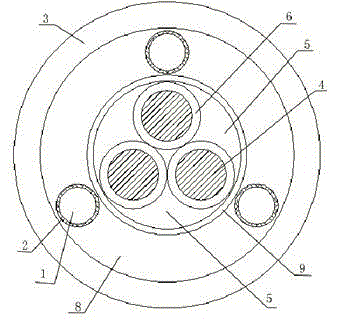

[0015] A high-performance photoelectric composite cable of the present invention is characterized in that it includes at least three conductors 4, all of which are wrapped with an insulating layer 6, and all conductors 4 wrapped with insulating layers 6 are wrapped by a shielding layer 9, and the shielding layer 9 and the insulating layer The gaps between 6 are filled with fillers 5, the shielding layer 9 wraps the inner sheath layer 8, and the inner sheath layer 8 is provided with at least 3 optical fibers 1, the optical fiber 1 is wrapped with non-woven fabric 2, and the inner sheath The layer 8 is wrapped with an outer sheath layer 3, and the shielding layer 9 is a three-layer structure, including copper foil, and both sides of the copper foil are provided with aluminum foil.

[0016] The filler material 7 is a fire-resistant water-blocking tape, which includes a mica layer, glass fiber grids are bonded to both sides of the mica layer, and a film made of water-blocking powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com