Multilayer shielding film and manufacturing method thereof

A multi-layer shielding and manufacturing method technology, applied in the fields of magnetic/electric field shielding, chemical instruments and methods, lamination, etc., can solve the problems of weak shielding ability, inability to completely prevent electromagnetic pollution, secondary pollution of space environment, etc., and achieve Good shielding and absorbing properties, prevention and control of electromagnetic radiation pollution, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

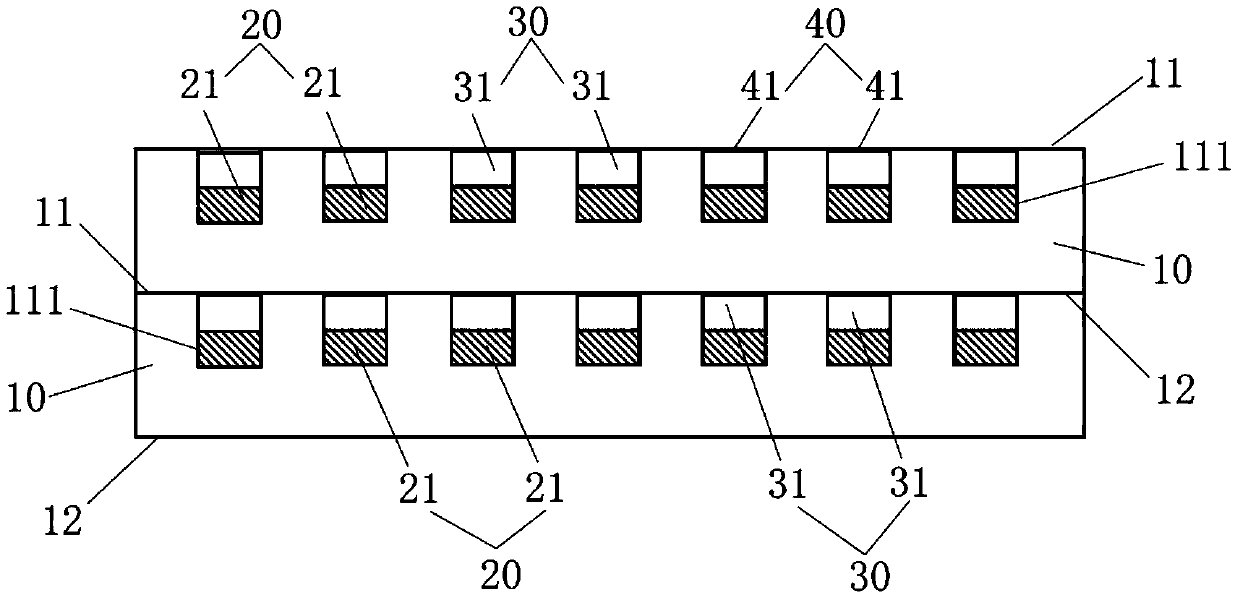

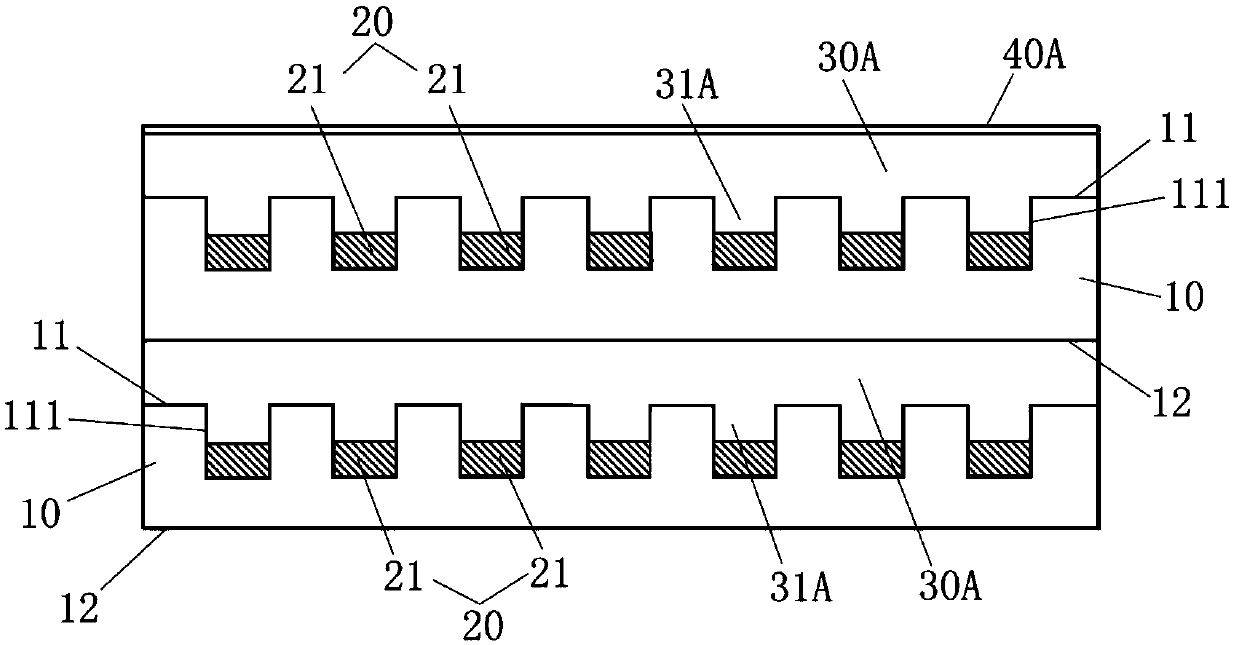

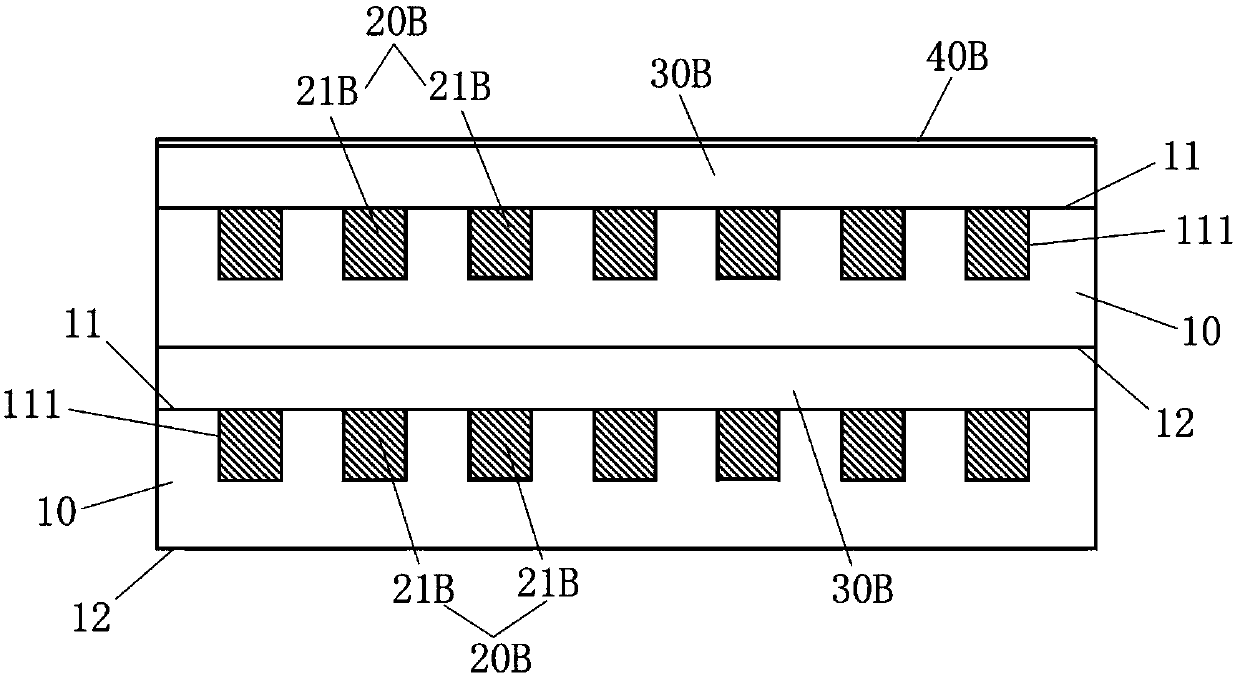

[0041] like figure 1 The first preferred embodiment of a multilayer shielding film of the present invention is shown, the shielding film includes two superimposed unit films, an adhesive layer is arranged between the two unit films, and the two unit films The films are connected by the adhesive layer. The unit film includes a substrate layer 10 , a shielding layer 20 and a wave-absorbing layer 30 . The substrate layer 10 has a first surface 11 and a second surface 12 opposite to each other. The first surface 11 has several grooves 111 uniformly distributed on the first surface 11 . The grooves 111 form interconnected grids on the first surface 11, and the grids may be periodic or aperiodic. figure 1 The cross-section of the groove 111 is rectangular, but it should be noted that the cross-section of the groove 111 can also be set as a square or trapezoid. The two unit films are respectively connected to the adhesive layer through the first surface 11 and the second surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Separation distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com