Threading pipe joint

A technology for threading pipes and pipe bodies, which is applied in the field of threading pipe joints, can solve the problems of easy looseness, weak fastening, complex structure, etc., and achieves the effects of good protection and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

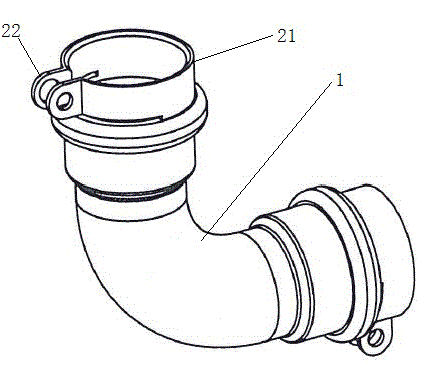

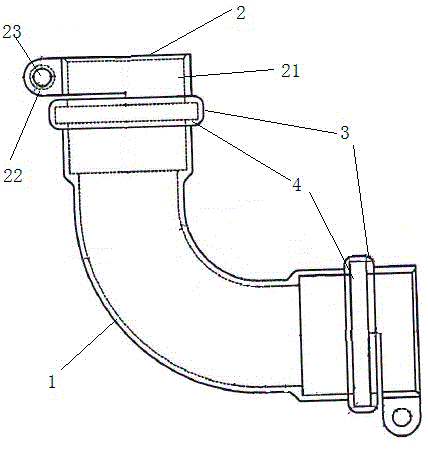

[0024] Such as Figure 1 to Figure 3 As shown, the threading pipe joint of the present invention includes a pipe body 1, and a fastening device 2 is provided on the outside of the two ports of the pipe body 1. The pipe body 1 is a hollow elbow, and the lumen of the pipe body 1 can accommodate the line pipe. etc. The fastening device 2 includes a fastening piece 21 and fixing pieces 22 arranged at both ends of the fastening piece 21. The fastening piece 21 is a sheet-like structure, and the fastening piece 21 is bent into an unclosed ring. The fastening piece 21 A sheet-shaped fixing piece 22 is provided at both ends, the annular diameter of the fastening piece 21 is greater than or equal to the inner diameter of the lumen of the tube body 1, and the part of the fastening piece 21 away from the fixing piece 22 is connected to the port of the tube body 1, that is, fastened The two ends of the sheet 21 are separated from the port of the pipe body 1, so that the fastening device ...

Embodiment 2

[0030] Such as Figure 4 , Figure 5 As shown, the present embodiment improves the pipe body 1 on the basis of embodiment 1, making the bent pipe body 1 into a straight pipe body to adapt to different installation conditions, and the rest of the structure is the same as that of embodiment 1, here The description is not repeated.

Embodiment 3

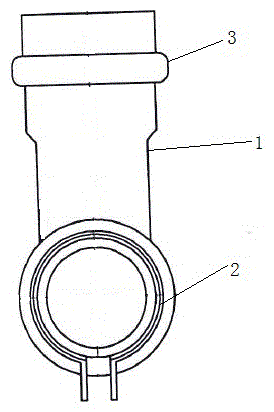

[0032] Such as Image 6 , Figure 7 As shown, this embodiment improves the pipe body 1 again on the basis of embodiment 2, only a fastening device 2 is provided at one port of the pipe body 1, and the other port of the pipe body 1 is set as a threaded pipe mouth, in order to adapt to different installation conditions.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap