A continuous oil pouring fried poached egg frying machine formed by mold

A technology of mold forming and poached eggs, which is applied in the direction of oil/fat baking, etc., can solve the problems of oil waste, high temperature oil safety hazards, and poor working environment for personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

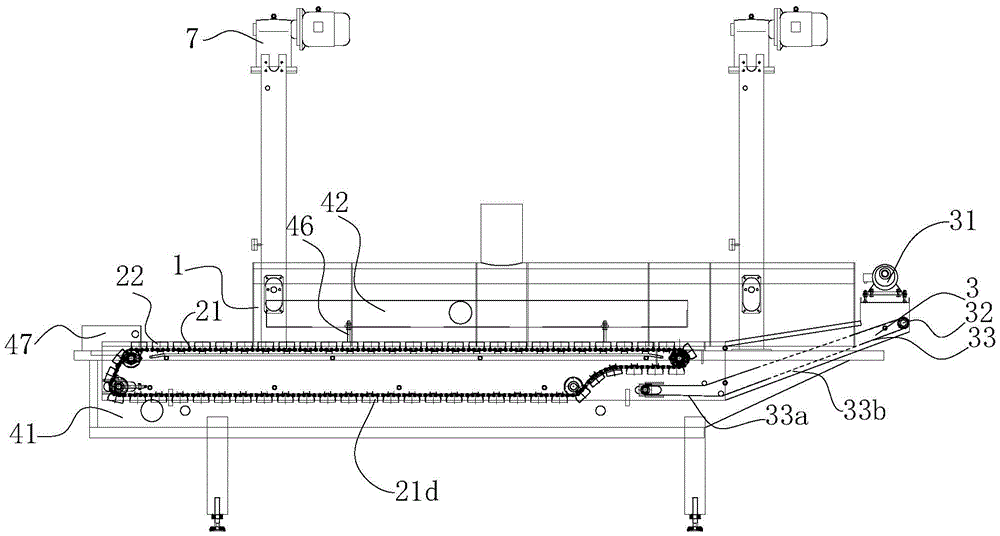

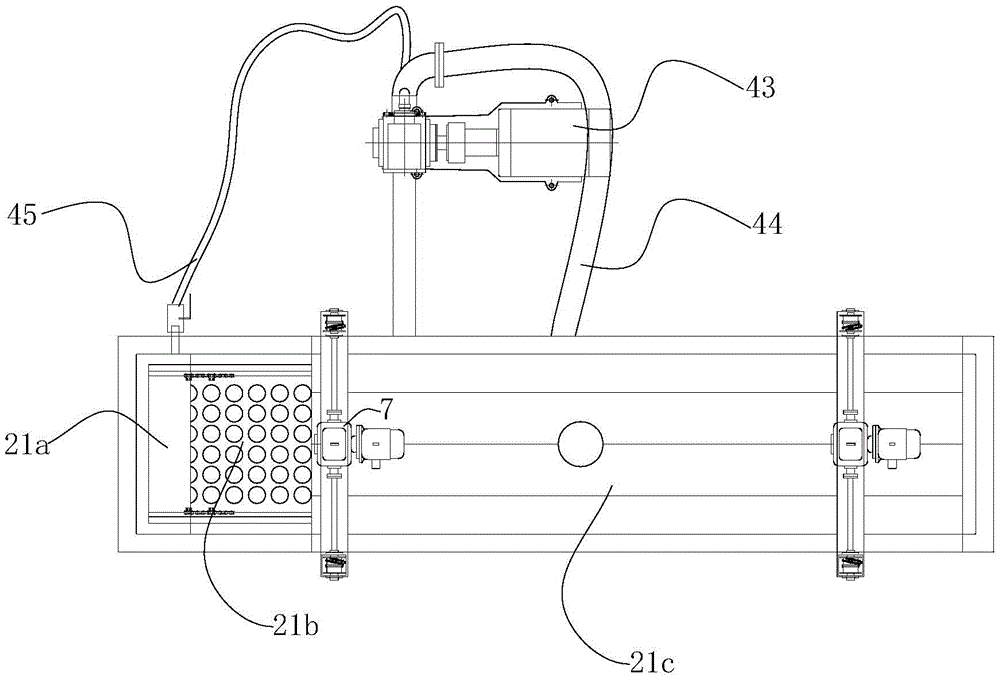

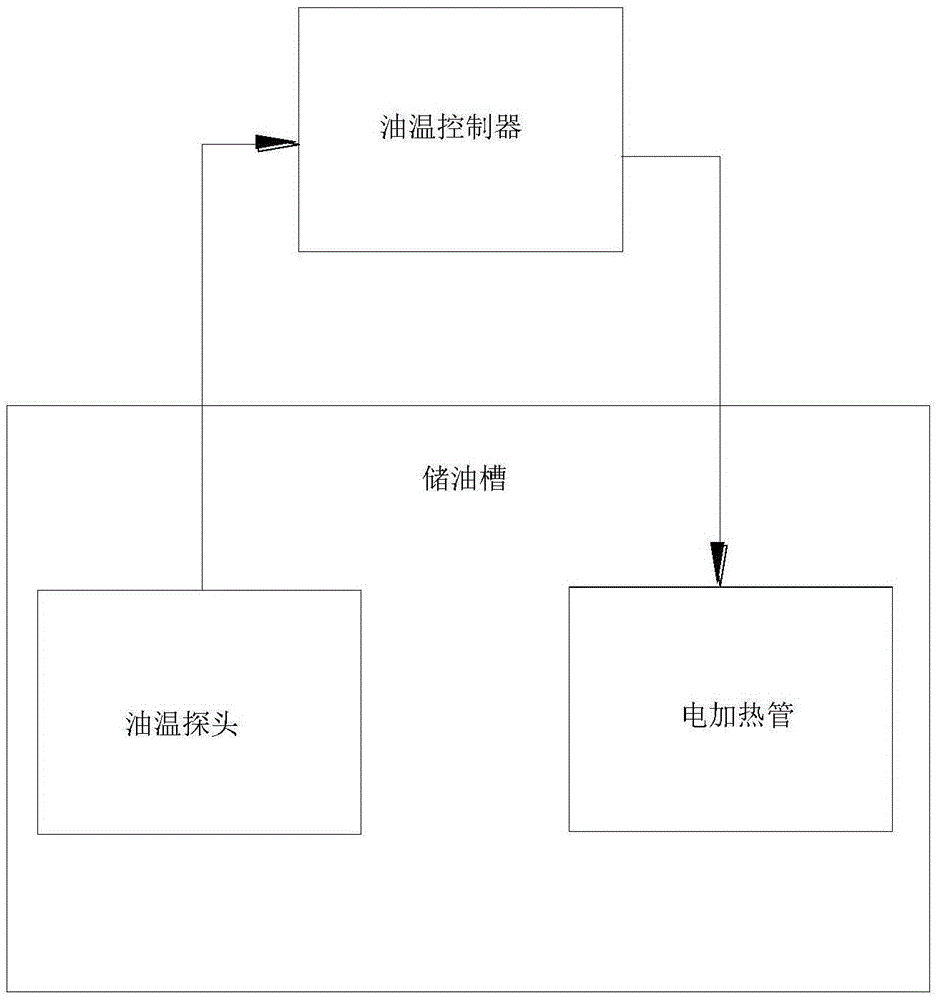

[0020] Embodiment 1: as figure 1 , figure 2 and image 3 Shown is a continuous oiling type frying poached egg frying machine formed by moulds. The poached egg frying machine includes a chassis 1, a frying mechanism for batch frying poached eggs, a poached egg delivery device 3 and an edible oil recycling system. Wherein, the frying mechanism for frying poached eggs in batches and the poached egg delivery device 3 are both installed on the cabinet 1, and the position of the poached egg delivery device 3 corresponds to the output end of the frying mechanism.

[0021] Above-mentioned deep-frying mechanism comprises the conveying device 21 that is installed on the cabinet 1 and a plurality of poached egg molds 22 that are used for frying poached eggs, and a plurality of poached egg molds 22 are all fixed on the conveying device 21, by arranging a certain number of poached egg molds 22 can To realize batch frying of poached eggs, a plurality of poached egg molds 22 can be arrang...

Embodiment 2

[0032] Embodiment 2: The above-mentioned conveying device 21 is a circular conveyor belt structure, and the rest of the structures are repeated in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com