A heating reboiler

A reboiler and preheating chamber technology, applied in the field of alcohol distillation, can solve the problems of short service life and inability to make full use of heat energy, and achieve the effects of long service life, full use of energy, and accelerated vaporization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

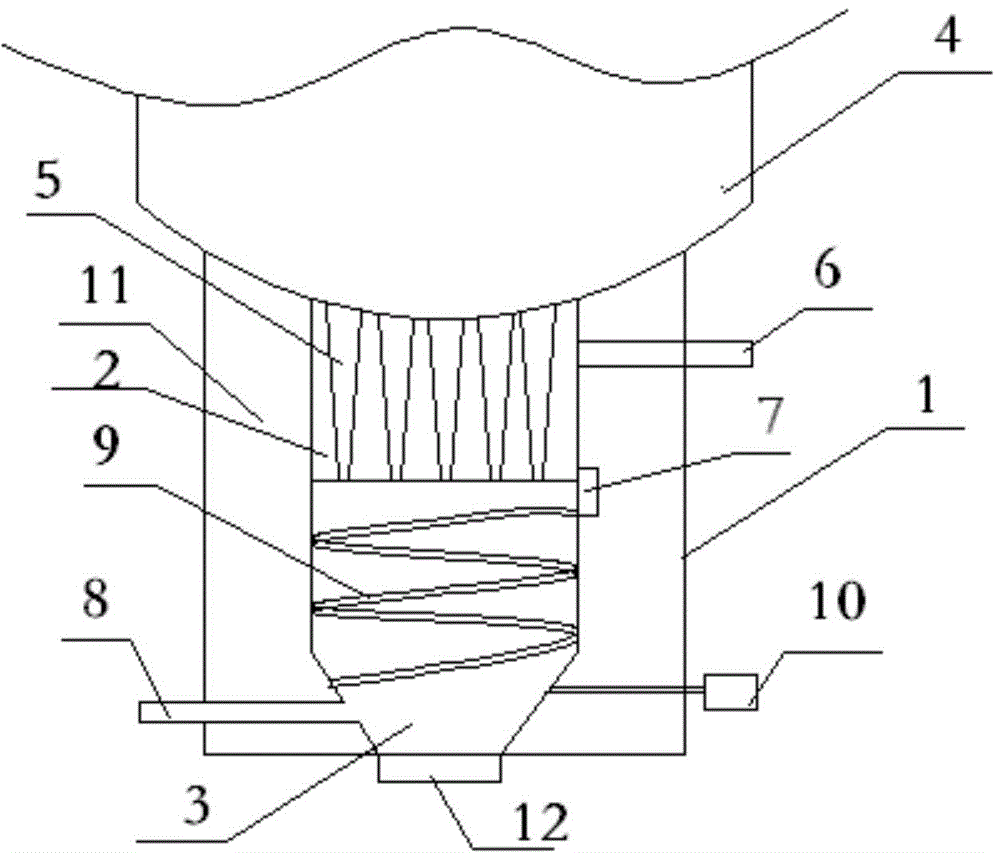

[0017] like figure 1 As shown, a heating reboiler of the present invention includes a reboiler body 1, and the interior of the reboiler body 1 is divided into a reboiler chamber 2 and a preheating chamber 3, and the reboiler chamber 2 is connected to the bottom of a rectification tower 4 , the preheating chamber 3 is connected to the lower part of the reboiling chamber 2;

[0018] There are several funnel-shaped pipes 5 inside the reboiler chamber 2 , the large mouth end of the funnel-shaped pipe 5 is connected to the bottom of the rectification tower 4 , the small mouth end is connected to the preheating chamber 3 , and the upper part of the reboiler chamber 2 It has a hot steam inlet 6, and the lower part has a hot steam outlet 7;

[0019] The top of the preheating chamber 3 has several small holes, which are respectively connected to the small mouth ends of the funnel-shaped pipeline 5, the bottom of the preheating chamber 3 has a material inlet 8, and the outside of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com