Spray gun

A spray gun and blocking part technology, which is applied to spray devices, liquid spray devices, etc., can solve the problems of difficult switching of operating parts, large water pressure area, large switching force, etc., and achieves light switching force, low internal pressure, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

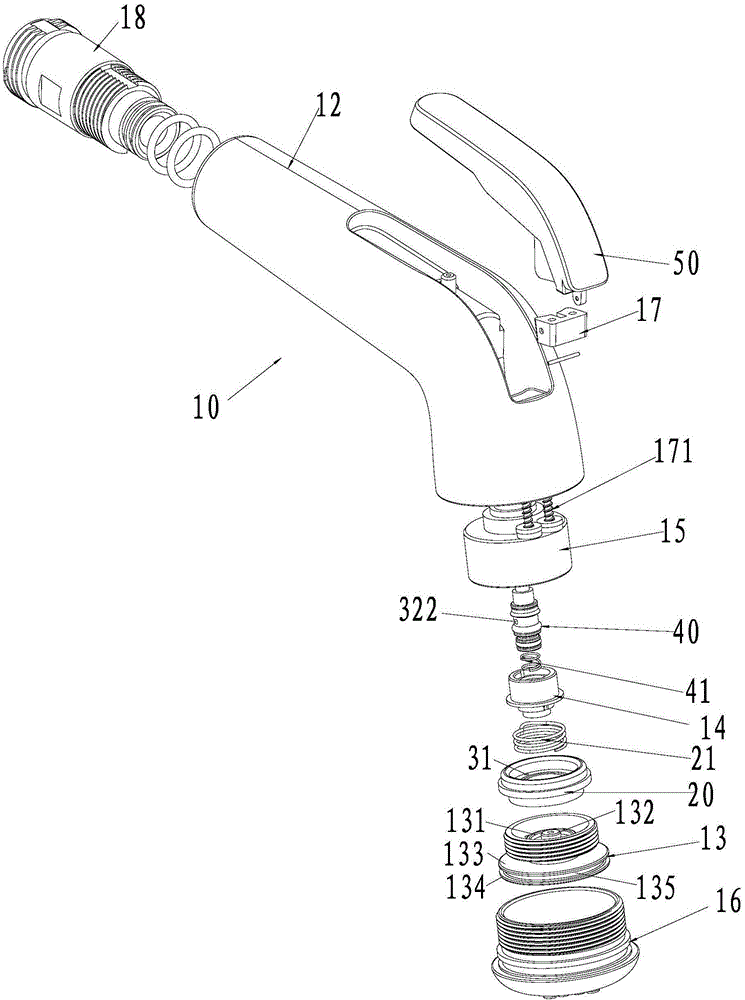

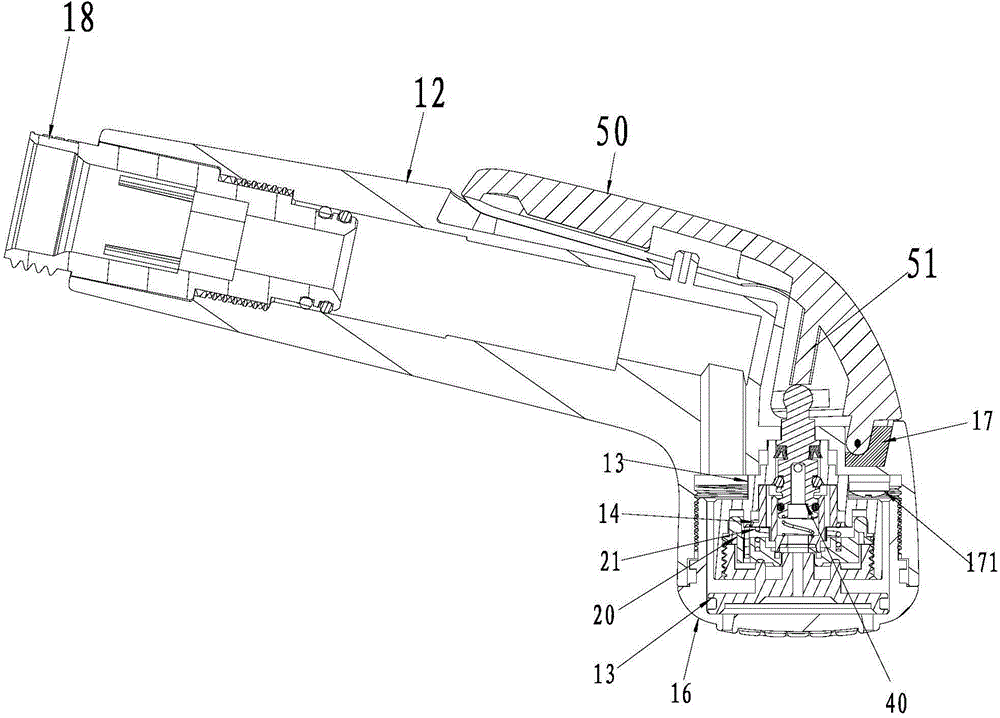

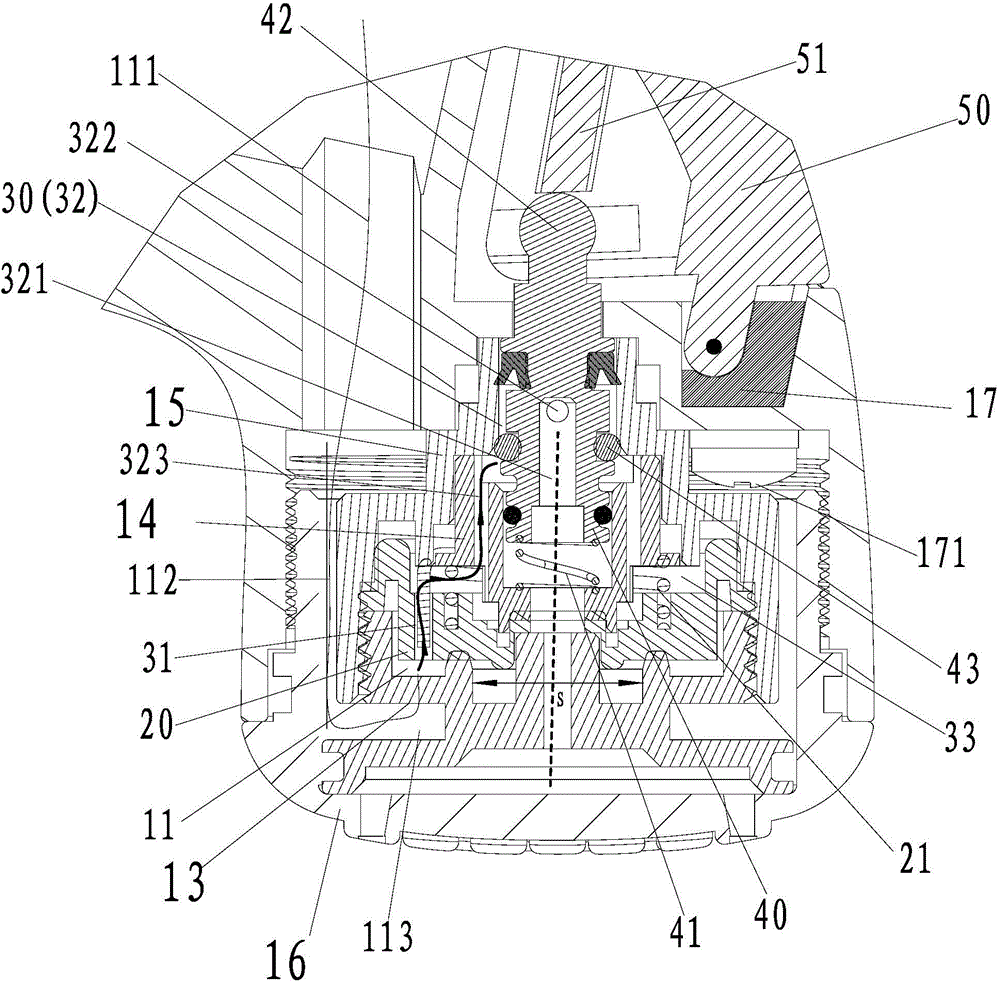

[0033] Please check Figures 1 to 7 , which shows a schematic structural view of the spray gun, including a fixed part 10 , a blocking part 20 , a bypass waterway 30 , a valve seat 40 and an operating part 50 .

[0034] This fixed part 10 is provided with a main waterway 11 . In a specific structure, the fixing part 10 includes a main body 12 , a water diversion body 13 , a water diversion seat 14 , a fixing seat 15 and a cover 16 . The outer peripheral edge of the cover 16 extends along the direction vertical to the cover 16 to form a first peripheral wall, and the first peripheral wall is sealed and fixed in the end port of the body 12 , such as threaded. The water diversion body 13 leans against the surface cover 16 and is located in the first peripheral wall, the fixing seat 15 is located in the first peripheral wall and the top supports the body 12, and the water diversion body 13 is fixed with a second Peripheral wall 136, the outer peripheral edge of the fixing seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com