Compression/recovery valve sheet cutting device for automobile inflatable shock absorber

A shock absorber and recovery valve technology, applied in metal processing and other directions, can solve the problems of many workers, low efficiency, and difficulty in accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

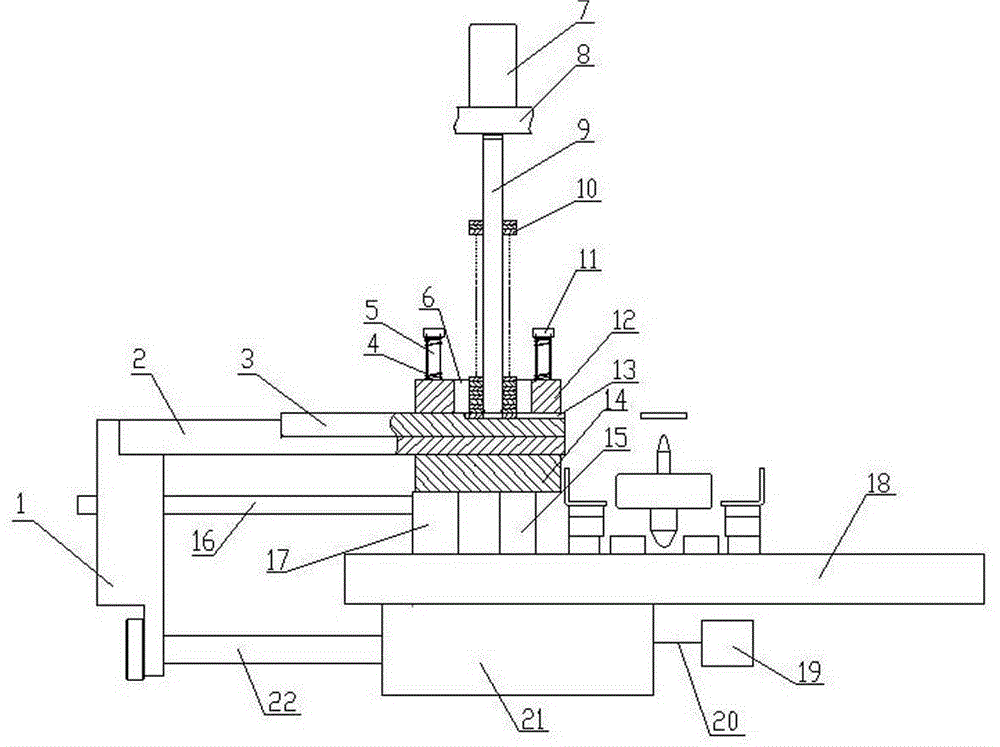

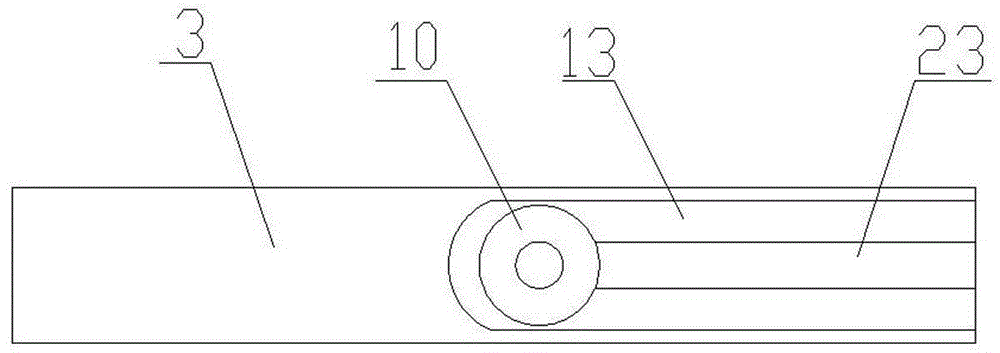

[0014] like figure 1 and figure 2 As shown, the cutting-out device for the compression / recovery valve plate of the automobile pneumatic shock absorber of the present invention includes a base plate 18 and a controller 19 . A lower positioning block 14 is arranged on the base plate 18 , and the lower positioning block is fixed on the base plate 18 by means of a support plate 17 and a column 15 . The upper positioning block 12 is arranged on the lower positioning block 14, and the edge of the lower positioning block 14 is processed with four vertical screw holes, and the edge of the upper positioning block 12 is processed with four vertical through holes. The number of vertical through holes on the hole and the upper positioning block 12 is equal and corresponding, and a first guide rod 5 is arranged between the corresponding vertical through holes and the vertical screw holes, and the lower end of the first guide rod 5 is processed with threads and Screw in the vertical scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com