Material cutting and feeding device of cap making machine

A technology of feeding device and cutting knife, which is applied in the field of packaging machinery, can solve the problems that the feeding and discharging modules cannot realize fast and accurate feeding, and achieve the effect of convenient assembly and maintenance, simple structure, fast and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

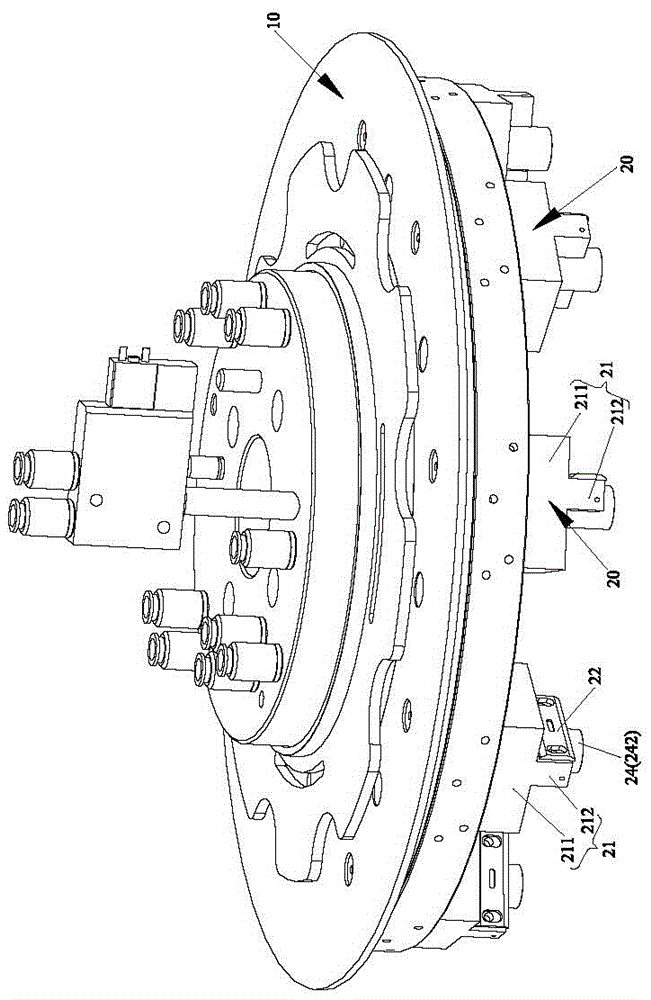

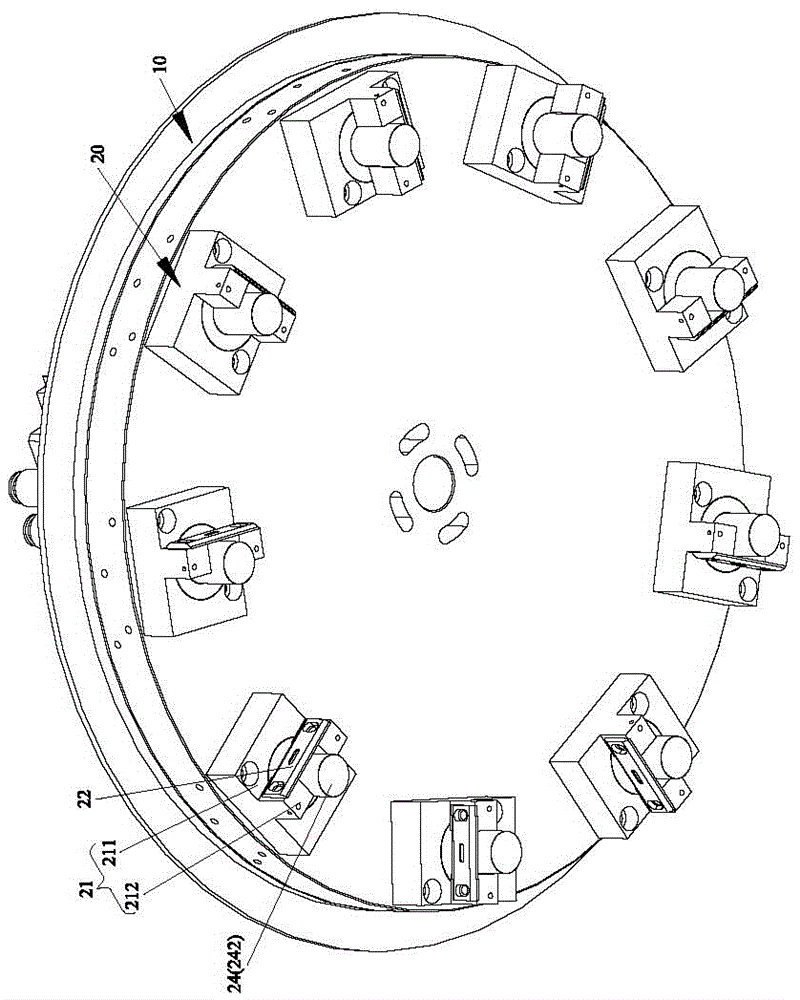

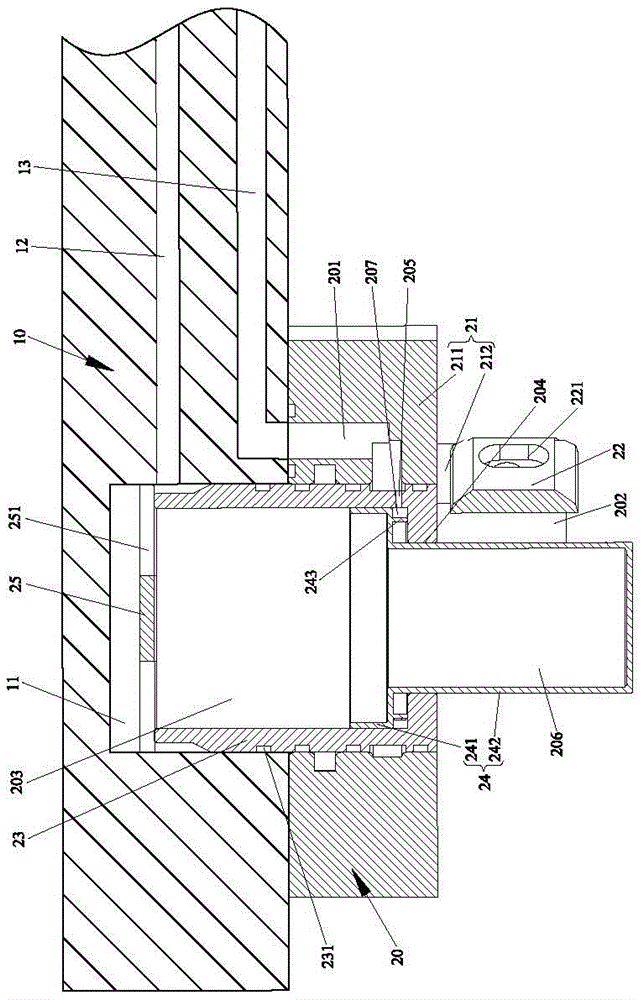

[0034] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a turntable 10 and a plurality of cutting and feeding modules 20 .

[0035] The periphery of the bottom surface of the turntable 10 is concavely provided with a plurality of accommodating cavities 11, and for each accommodating cavity 11, a first air passage 12 and a second air passage 13 are arranged in the turntable 10, and the first air passage 12 communicates with and accommodates Inside the upper end of cavity 11.

[0036] The plurality of cutting and feeding modules 20 are evenly spaced on the bottom periphery of the turntable 10 , and each cutting and feeding module 20 includes a fixing seat 21 , a cutting knife 22 , a fixing casing 23 and a pressing column casing 24 .

[0037] The fixing base 21 includes a base 211 and two columns 212, the base 211 is provided with a third air channel 201, the third air channel 201 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com