Method for producing an endless transport belt

A technology of endless transmission and transmission belt, which is applied in the direction of belt fasteners, conveyors, mechanical equipment, etc., can solve the problems of small ink concentration, reduce the quality of printing samples, etc., and achieve the effect of reducing grinding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

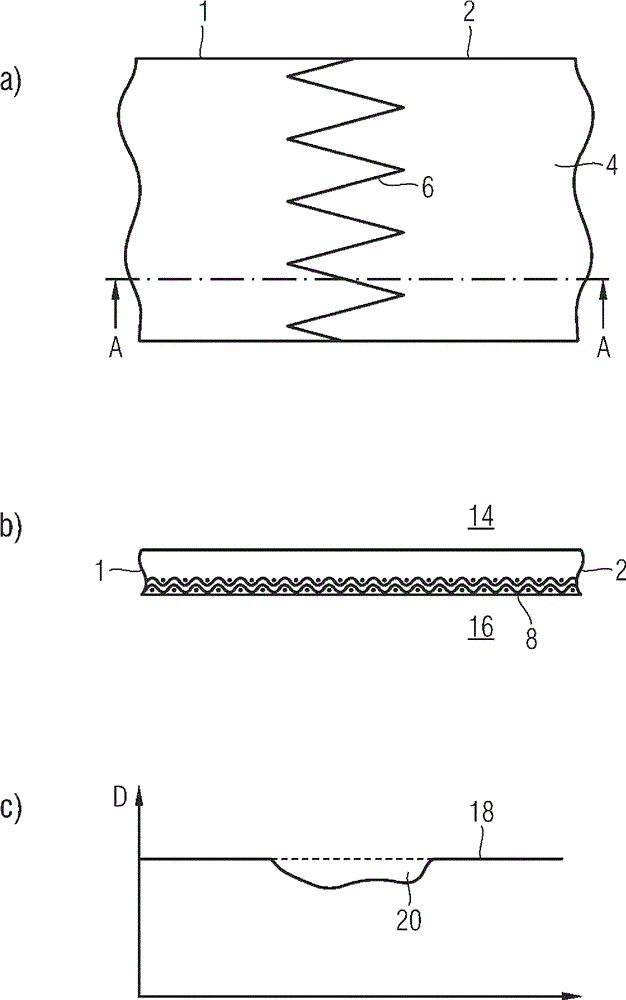

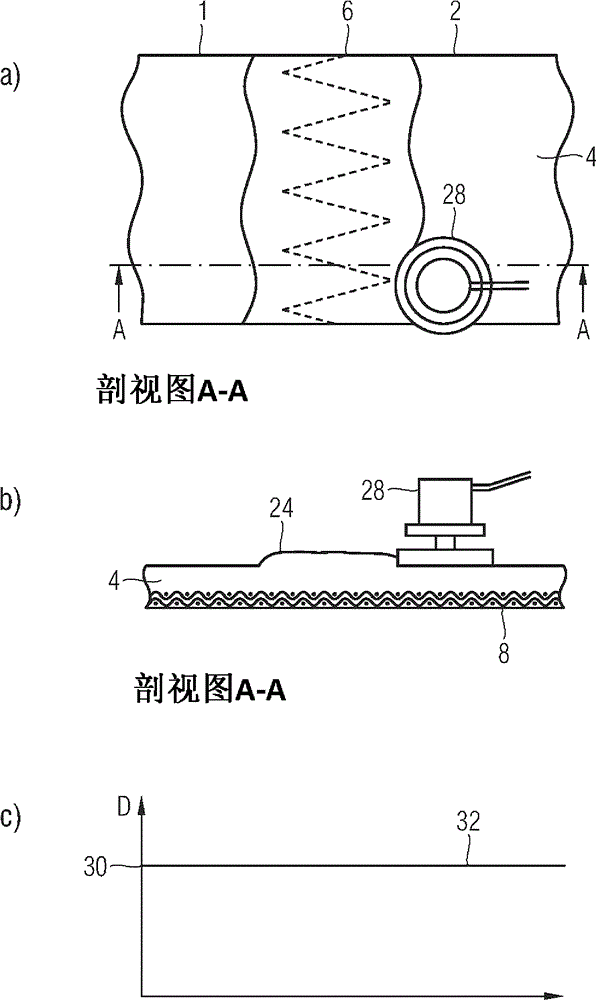

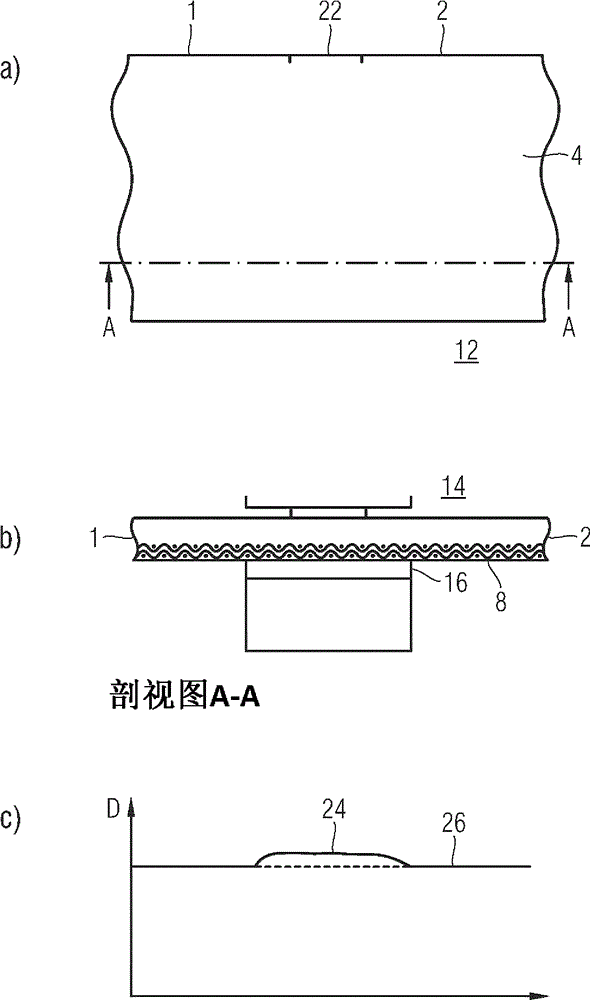

[0023] in accordance with figure 1 In the examples, the welding process without additional material addition is described. The ends 1 , 2 of the conveyor belt 4 are designed in a wedge-tooth shape and engage with each other at the seam 6 . figure 1 In b, a cross section through the conveyor belt 4 in the region of the weld seam, ie the seam 6 , is shown during the welding process. The structure of the conveyor belt 4 can be seen more clearly in cross section. It consists of a textile fabric layer 8 and a cover layer 10 which is coated with an adhesive. The welding process is carried out by means of a heat press 12 comprising an upper heating plate 14 and a lower heating plate 16 with which temperatures of approximately 160° C. can be achieved. The two ends 1 , 2 of the conveyor belt 4 are connected to one another in a materially bonded manner by means of the heating plate. If according to figure 1 The thickness sectional view 18 of c shows that the groove 20 is formed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com