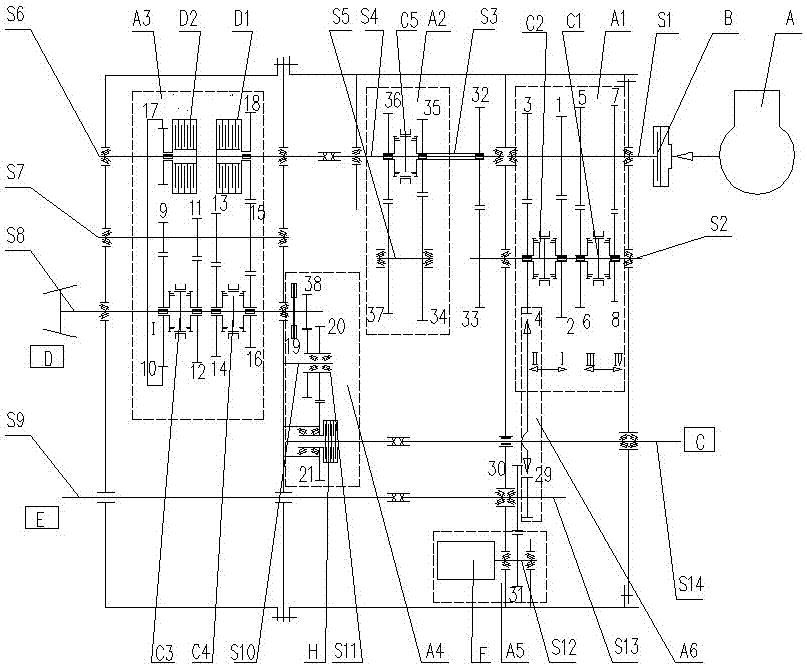

Power reversing tractor drive train with primary clutch between primary and secondary transmissions

A technology of main clutch and transmission device, which is applied in the field of tractors, can solve the problems of only using the meshing sleeve for shifting, increased moment of inertia, and long shifting time, etc., and achieves the effects of high operating efficiency, compact and reasonable structure, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings.

[0013] The power reversing tractor transmission system of the main clutch between the main and auxiliary transmissions includes: main transmission A1, crawler transmission A2, auxiliary transmission A3, transfer case A4, oil pump drive A5, power output device A6, and Meshing driving gear 33, constant meshing driven gear 32, power output shaft rear shaft S9, power output front shaft S13, oil pump driving driving gear 30, torsion shock absorber B, front output shaft S14; characterized by: main transmission device A1 and The crawler gear device A2 is meshed and connected by the normally meshed driving gear 33 and the normally meshed passive gear 32, the crawler gear device A2 and the auxiliary transmission device A3 are connected by a spline sleeve, and the auxiliary transmission output shaft S8 in the auxiliary transmission device A3 is divided into A4. The first-stage driving gear of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap