Method for processing novel anti-dazzle glass

A processing method and anti-glare technology, applied in the field of glass, can solve the problems of unsuitable OGS glass, uneven haze, insufficient adhesion, etc., and achieve the effect of good film adhesion, good adhesion, and guaranteed cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

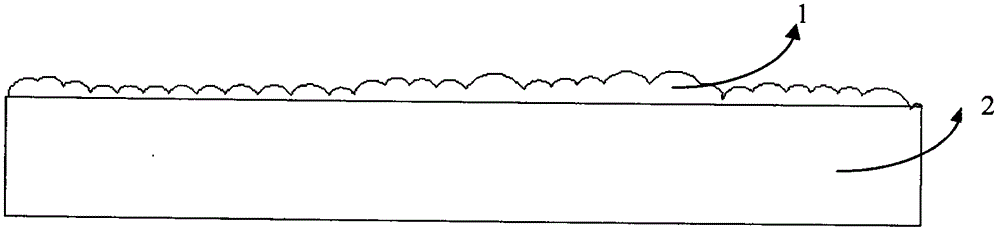

[0017] The present invention is applied to the processing of anti-glare glass, such as figure 1 As shown, the anti-glare glass includes a glass substrate 1, on which is a silicone resin anti-glare coating layer 2 that has undergone the above steps, and the silicone resin film layer is a rough film layer.

[0018] The processing method of the anti-glare glass comprises the following steps:

[0019] Step S1, providing silicone resin potion and glass substrate 1;

[0020] Step S2, using an ion electric gun to clean the surface of the glass substrate 1;

[0021] Step S3 uses an IR tunnel furnace to preheat the glass substrate 1 (heating temperature 120°C-150°C);

[0022] Step S4, using a high-pressure atomizing spray gun to spray the silicone resin syrup on the surface of the glass substrate 1 to form a rough silicone resin film layer 2;

[0023]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com