Integrated paraffin granulating device

A granulation device and paraffin technology, which are applied in the petroleum industry, wax physical treatment, hydrocarbon oil treatment, etc., can solve the problems of not being suitable for small-scale and experimental production, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

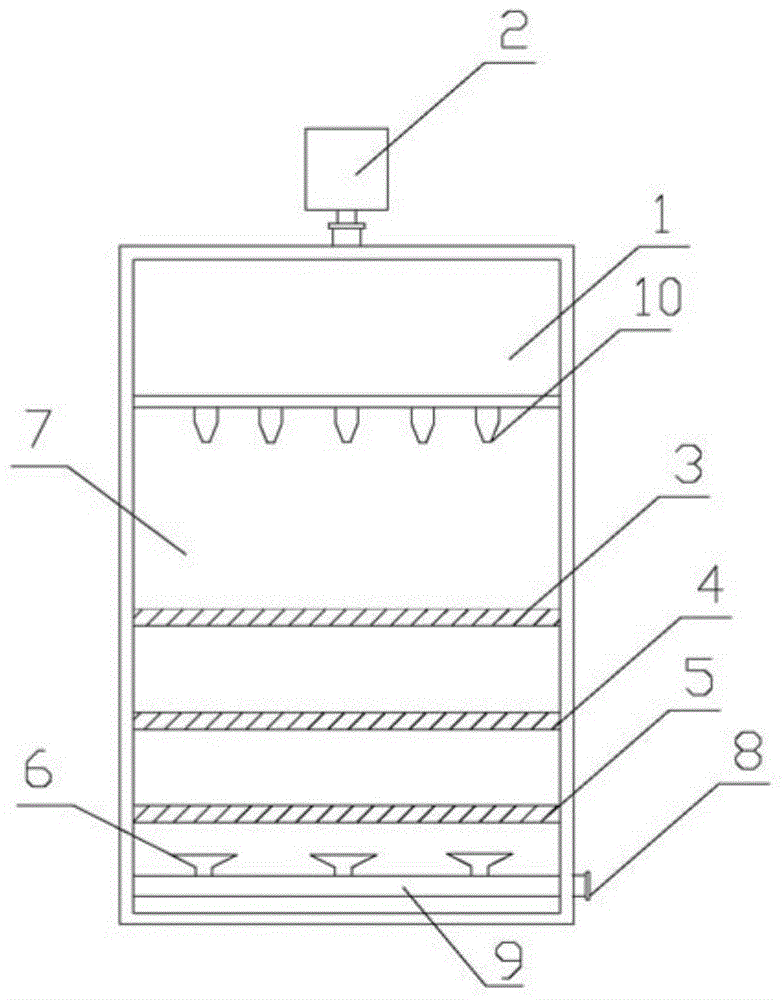

[0012] An integrated paraffin wax granulation device, the device includes a liquid wax storage chamber 1 and a granulation chamber 7; the granulation chamber 7 is provided with three partitions, wherein the uppermost partition is the first sieve plate 3, the middle layer The dividing plate is the second sieve plate 4, and the pore diameter of the first sieve plate 3 is larger than the pore diameter of the second sieve plate 4, and the bottom layer is a receiving plate 5, and the receiving plate 5 is provided with holes for ventilation. The diameter is 20% of the average diameter of the paraffin wax particles; the bottom of the granulation chamber 7 is provided with a spray nozzle 6, and the spray nozzle communicates with the spray main pipe 9; the liquid wax storage chamber 1 is located at the top of the granulation device, and its top An air compressor 2 is provided, and a controllable flow nozzle 10 is provided at the bottom thereof. The top of the liquid wax storage chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com