Self-circulating brown gas electrolysis module

A Brownian gas and electrolyte technology, applied in the field of electrochemistry, can solve the problems of complex assembly of electrolysis modules, low current utilization rate, and low gas production efficiency, and achieve improved electrolysis gas production efficiency, high current utilization rate, and improved production efficiency. The effect of gas efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

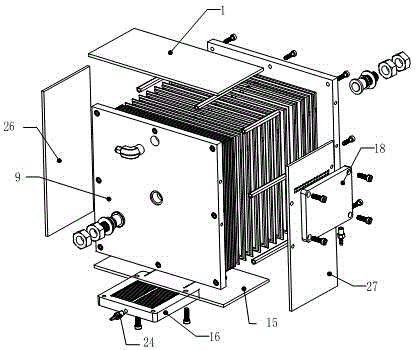

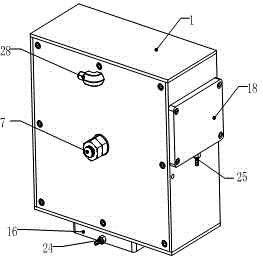

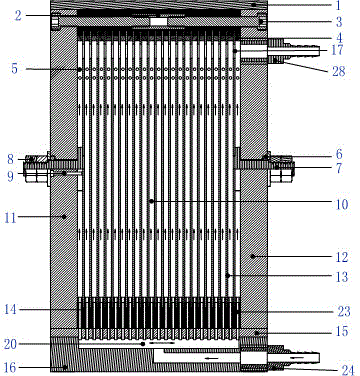

[0025] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Including a shell, the shell is spliced by the front end plate 11, the rear end plate 12, the left side plate 26, the right side plate 27, the bottom plate 15 and the top plate 1. The tightening screw is tightened back and forth together with the electrode plate and fixed, the end face area of the front and rear end plates is larger than the end face area of the electrode plate, and the left and right side plates and the bottom and top plates are covered to form a space around the back, and the tightening screw is along the front 1. The surrounding space of the rear end plate is arranged through the interval space, and the tension screw rod is composed of the middle screw sleeve 2 and two bolts 3. At the same time, the casting resin sealing layer 14 is filled in the surrounding interval space to form a resin casting type splicing se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com