pneumatic pile driver

A pile driver and gas circuit technology, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of easy deflection, low efficiency, and potential safety hazards of driven piles, and achieve rapid and smooth exhaust and air intake The effect of rapidity and shortened cycle process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] gas The dynamic pile driver is a mechanized hand tool that uses compressed air as the power source to generate mechanical impact and strike the workpiece object. It is suitable for hammering steel drill piles and other similar piles to the ground on the construction site. It is a building frame and It is an ideal piling tool for electric ground piles and other industries. It can replace traditional manual sledgehammer strikes. It has large striking force, fast striking speed, high efficiency, convenient operation and low labor intensity.

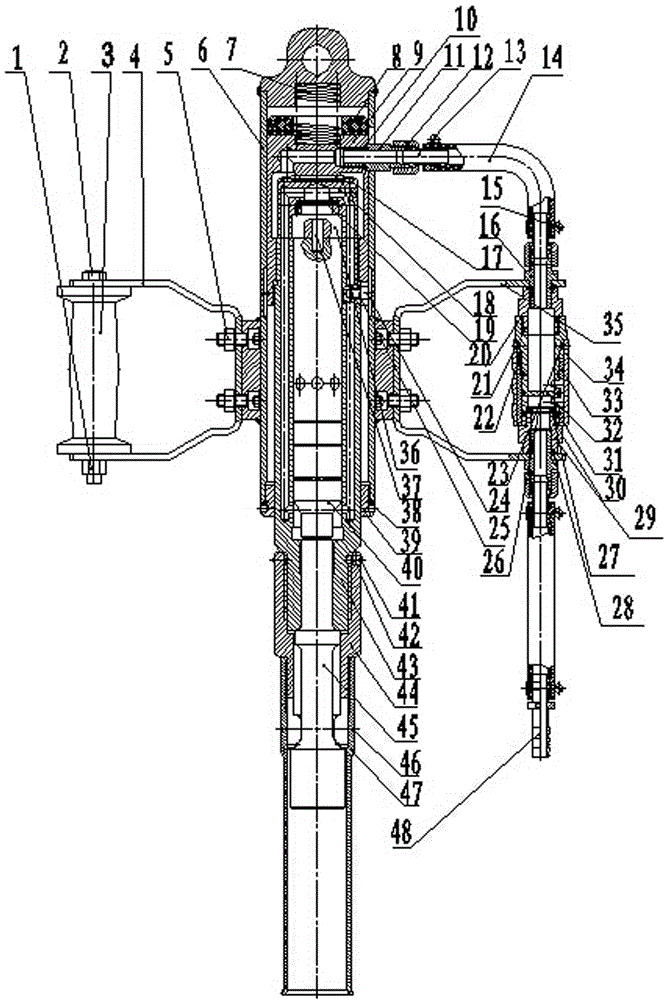

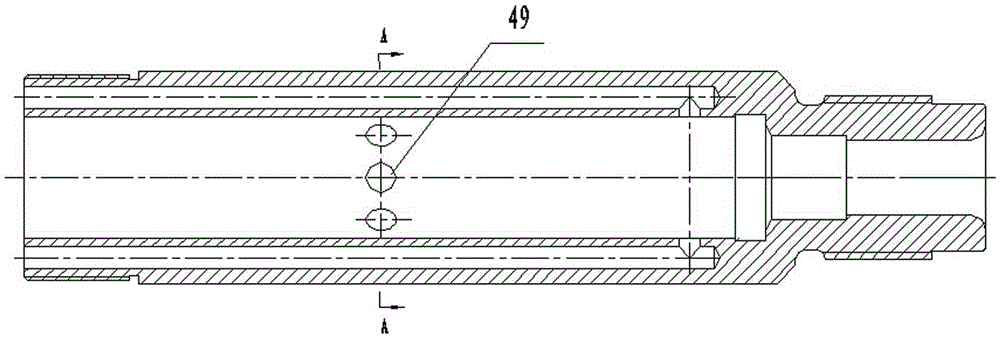

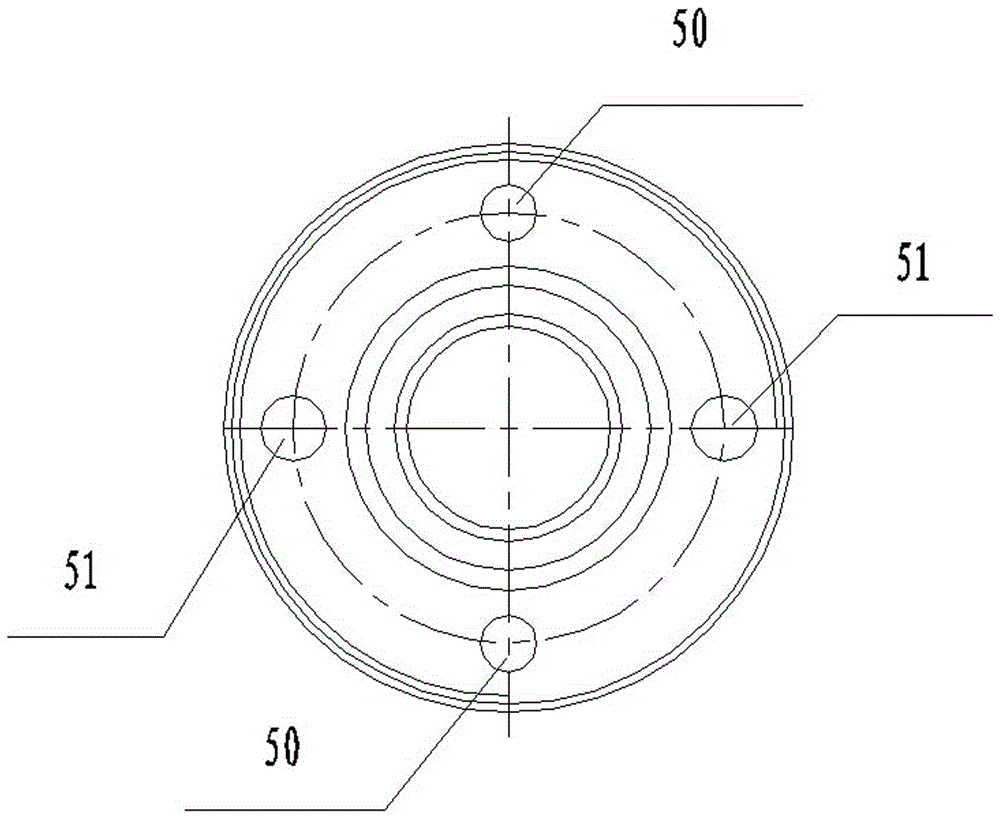

[0022] Concrete structure of the present invention sees figure 1 As shown, it includes a casing 6, a cylinder body 43, a valve cabinet 18, a valve plate 19, a valve cover 36, a coupling sleeve 9, an impact rod 45, and a hammer body 40. The coupling sleeve 9 is placed on the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com