An assembled tailings water siphon return device

A siphon device, tailings water technology, applied in water supply devices, waterway systems, water conservancy projects, etc., can solve the problem of not considering the impact of flood control and structure of the tailings pond flood discharge system, exceeding the treatment scale of sewage treatment pools, and unable to achieve tailings. Zero discharge of mineral water, etc., to solve the problems of inconvenient construction, convenient maintenance, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

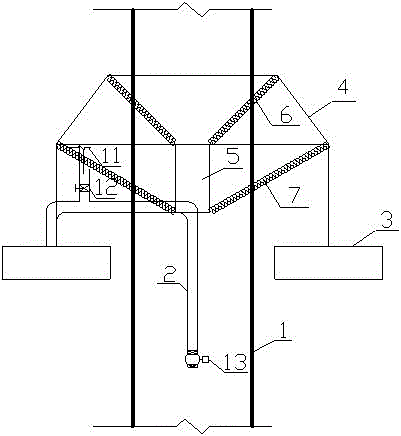

[0043] This embodiment includes a drainage well protection device and a siphon device fixed on the drainage well protection device.

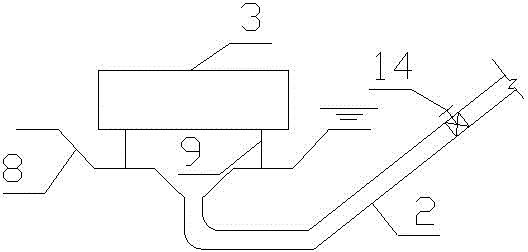

[0044] The drainage well protection device includes a central ring 5 and a steel frame 4, the central ring 5 is connected to the steel frame 4 through a suspension cable; the bottom of the steel frame 4 is equipped with a buoy 3 and a Hall anchor 10, and the buoy 3 is connected to the bottom of the steel frame 4 , Hall anchor 10 is connected with buoy 3 .

[0045] The steel skeleton 4 is composed of four single steel skeletons 4-1, each single steel skeleton 4-1 is provided with a connecting plate between adjacent ones, and each connecting plate is connected by bolts to form a tailings surrounding The backwater steel skeleton of the storage frame type reinforced concrete drainage well 1.

[0046]Described suspension cable comprises upper floor suspension cable 6 and lower floor suspension cable 7, and one end of upper floor suspension cable 6 i...

Embodiment 2

[0074] The difference between this embodiment and Embodiment 1 is that the outlet butterfly valve is an outlet manual butterfly valve 15, and the outlet manual butterfly valve 15 is provided with a gear, which is connected with the operating gear 17 arranged on the top of the siphon pipe 2 through a chain 16 to realize the outlet manual butterfly valve 15. opening and closing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com