Armored integrated wall and its construction method

A construction method and wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of single decorative plate, easy accumulation of dust, rough surface, etc., and achieve the effect of firm connection, avoiding potential safety hazards and improving earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]A construction method for an integrated wall, characterized in that the steps include:

[0054] The first step: install the open steel structure on the building frame;

[0055] Step 2: hang panels on the open steel structure;

[0056] Step 3: Preset the pipeline;

[0057] Step 4: Install interior wall panels on the open steel structure;

[0058] Step 5: Support formwork outside the inner wall panel;

[0059] The sixth step: pouring between the armored panel 3 and the inner wall panel;

[0060] Part Seven: Demoulding.

[0061] Using this method, the integrated structure of the wall and the armored panel 3 of the outer wall can be realized, and the armored panel 3 can be selected from different decorative materials according to actual needs, so that the wall realizes the concept of integration in the true sense. The wall can be put into application directly without adding other external structures or components, which avoids safety hazards of the external wall due to ...

Embodiment 2

[0063] A construction method for an integrated wall, characterized in that the steps include:

[0064] The first step: install the open steel structure on the building frame;

[0065] The first step of installing the open steel structure is specifically to install the open steel structure on the building frame after the building frame is built. The open steel structure includes multiple sets of columns, and each set of columns includes outer columns 5, inner columns 6. The column connecting plate 7 and the horizontal connecting angle steel 1 connecting the column, the outer column 5 is connected with the outer side of the beam plate of the building frame through the embedded steel parts, and the inner column 6 is respectively connected and fixed with the upper and lower beam plates of the building frame by expansion screws.

[0066] In the first step, the corresponding outer columns 5 and inner columns 6 are connected to each other through the column connecting plates 7, and t...

Embodiment 3

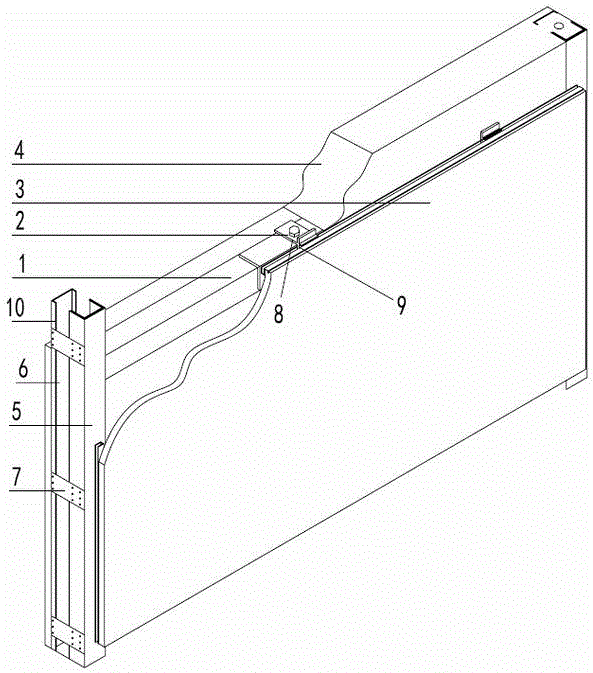

[0093] An armored integrated wall body includes at least two steel structure columns 10, and a transverse connecting angle steel 1 is arranged horizontally between two adjacent columns, and a connecting pendant 2 is arranged on the transverse connecting angle steel 1, and a connecting pendant 2 is arranged on the connecting pendant 2. An armored panel 3 is installed, and the two ends of the armored panel 3 are covered on the adjacent steel structure column 10, and the two adjacent columns and the armored panel 3 form a concave structure, and the concave structure is filled with It is a pouring material that meets the requirements of thermal insulation, fire protection and structural strength at the same time. The requirements for thermal insulation, fire protection and structural strength mentioned here refer to pouring materials that meet the national standards in terms of thermal insulation, fire protection and structural strength at the same time. By adopting the above stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com