Microcomputer intelligent grouting system and operation method thereof

An operation method and microcomputer technology, applied in the direction of mixing operation control, chemical instruments and methods, mixing plants, etc., can solve the problems of rapid loss of fluidity, easy segregation and stratification, and easy deviation of the proportion, so as to achieve full and dense grouting, Uniform slurry distribution and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

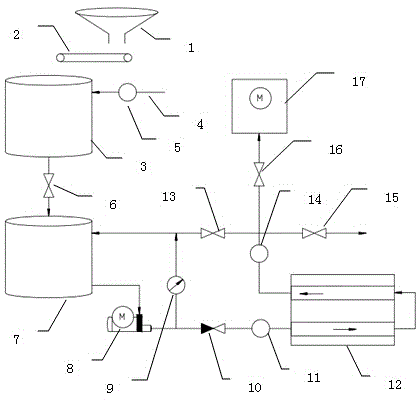

[0048] see figure 1 and 2, a microcomputer intelligent grouting system, comprising a silo 1, a belt weighing scale 2 positioned at the bottom of the silo 1, a high-speed mixing tank 3 located below the belt weighing scale 2, and a pulp storage tank 7 below the high-speed mixing tank 3 1. Connect the grouting pump 8 of the slurry storage barrel 7 through a rubber tube and the vacuum pump 17 connected to the grouting pump 8 through a tunnel 12, and connect the rubber tube between the high-speed mixing barrel 3 and the slurry storage barrel 7 There is a grouting valve 6 on it; a grouting stop valve 10 and a grouting pressure gauge 11 are arranged on the rubber tube connecting the grouting pump 8 and the tunnel 12; a rubber tube connecting the grouting pump 8 and the vacuum pump 17 There is a slurry return pressure gauge 14 and a vacuum valve 16;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com