Prefabricated evacuation platform for shield interval tunnel

A technology for evacuation platforms and interval tunnels, used in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of easy corrosion and durability, easy connection loosening, low installation accuracy, etc., to improve the quality and durability, and the connection is reliable. , Easy and fast installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

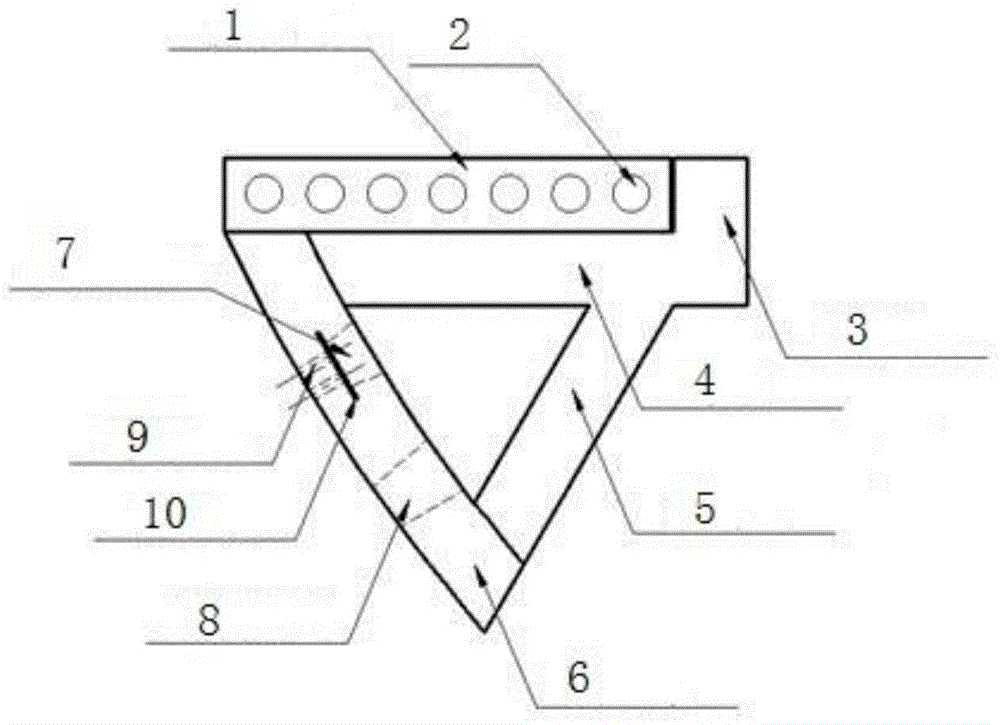

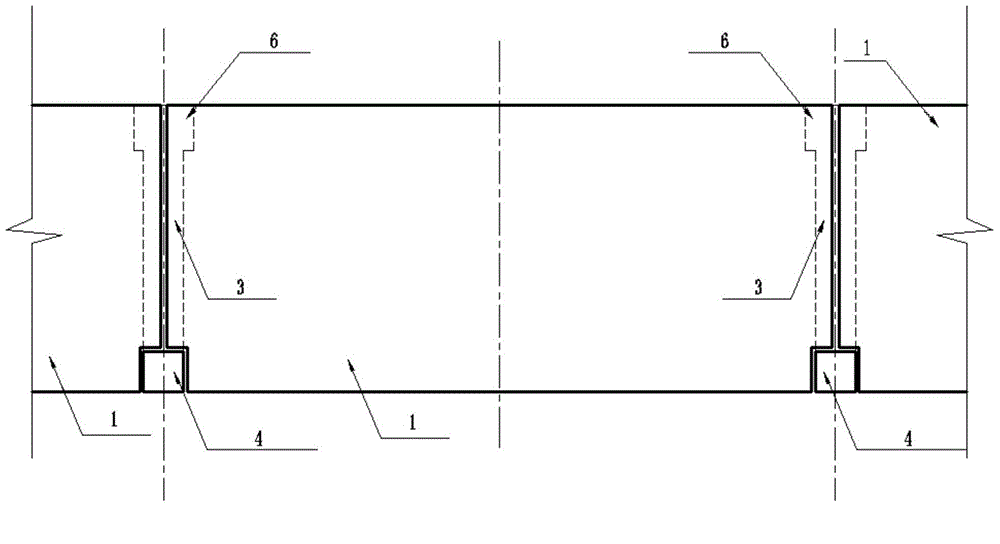

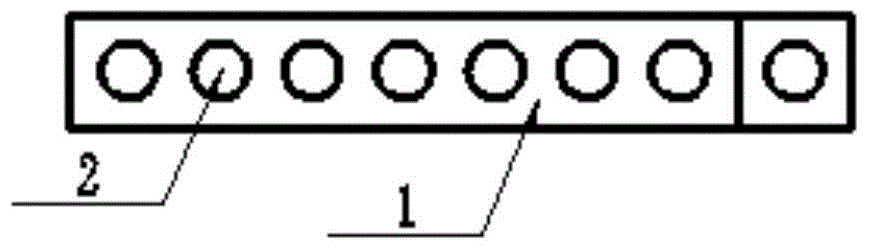

[0031] Such as figure 1 As shown, the prefabricated evacuation platform of the tunnel in the shield section is composed of the prefabricated evacuation platform bracket and the prefabricated platform plate 1 . The prefabricated platform slab 1 is provided with a reserved hole 2. The prefabricated hollow prestressed slab is used for industrial production in the factory. The hollow design is light in weight and high in strength, and by designing a reasonable length, it can adapt to different tunnel curve radii. The prefabricated platform slab 1 directly Erected in the middle of the prefabricated evacuation platform support, no other connection is required, and the installation and construction are convenient and quick. The prefabricated evacuation platform bracket is composed of beams 4, supporting inclined beams 5, arc-shaped bottom beams 6, and reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com