Measuring system and method for stacking alignment of containers

A measurement method and container technology, which is applied in the direction of measuring devices, measuring instruments, surveying and navigation, etc., can solve the problems of container stacking site difficulties, poor ambient light conditions, etc., and achieve the effect of eliminating interference and avoiding touching the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

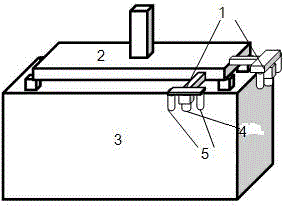

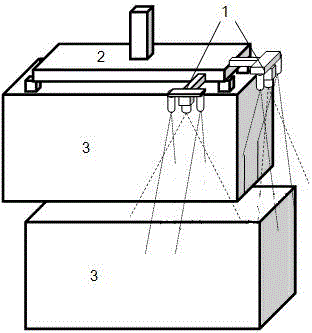

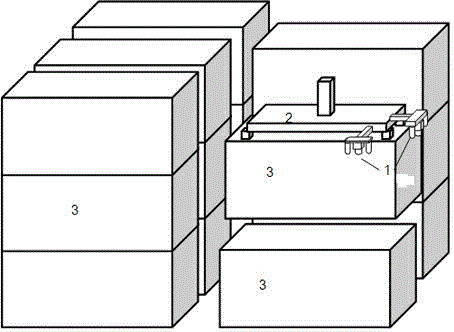

[0024] like figure 1 As shown, the container stacking and alignment measurement system of the present invention consists of two or more sets of line laser vision systems (two sets are taken here and below as examples), and each set of line laser vision systems includes several line lasers and a camera ( Two line lasers are used as an example here and below), and the laser lines projected by the line lasers are parallel. The line laser vision system is fixedly installed on the two adjacent sides of the spreader and protrudes slightly to the outside of the spreader. The exit port of the line laser and the camera lens are both vertically downward, and the laser line projected by the line laser is perpendicular to the edge of the container. , and can be projected onto the upper surface of the placed container, and the field of view of the camera can cover the position where the laser line is projected.

[0025] The camera can be configured with a filter matching the laser band to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com