Compressor fan over-temperature protection tester

A compressor and temperature protection technology, applied in thermometer testing/calibration, instruments, thermometers, etc., can solve the problems of not being able to ensure that the over-temperature protection function of the compressor is working normally, difficulties in over-temperature protection tests, cumbersome and difficult tests of protection tests, etc. , to achieve the effect of reducing test downtime, saving capital investment, and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

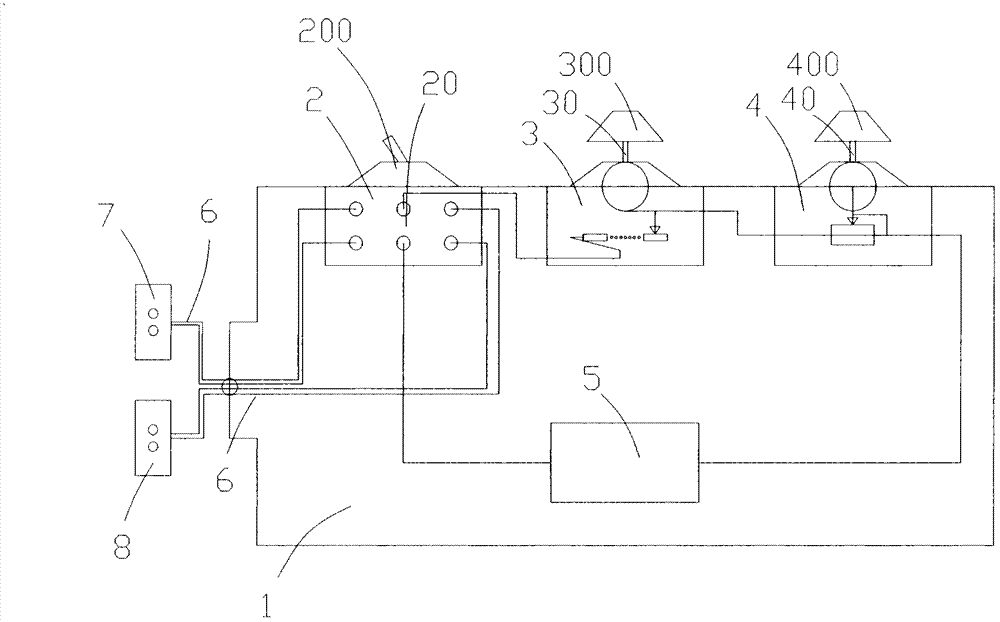

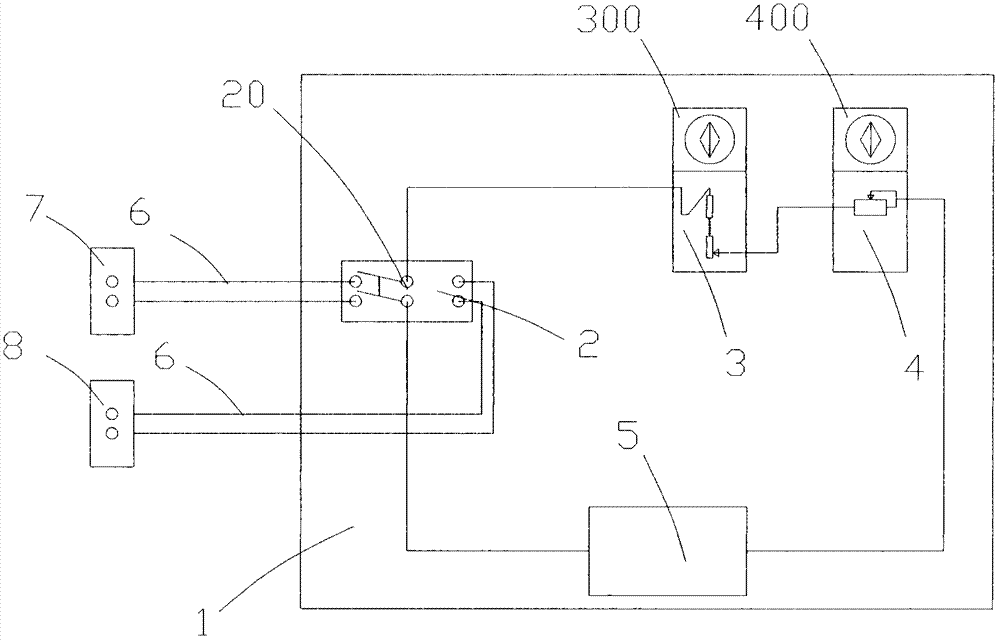

[0026] Get the pressure blower overtemperature protection tester of the present invention to the controller place on the pressure blower body, and prepare; this moment, the pressure blower controller collection temperature is 25 ℃ (stop state); the overtemperature protection will be overheated by the protection test quick plug The tester is directly connected to the controller of the compressor body; after the connection is completed, turn the button switch to the protection test position, and the test temperature can be raised by adjusting the knob, and it has risen to 103°C at this time; continue to adjust to make the test temperature When it rises to the alarm value, the alarm red light in the upper right corner of the control panel on the compressor body is on; at this time, it can be seen that the gas temperature is too high alarm appears on the control panel of the compressor body, and the alarm light is always on; at this time, the operation background computer Also rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com