High-efficiency energy-saving glass health pot

A high-efficiency, energy-saving, health-keeping pot technology, applied in the direction of boiling water utensils, special materials for cooking utensils, etc., can solve the problems of difficult application and promotion, increase production costs, low thermal efficiency, etc., achieve good anti-scalding and support, and speed up heating. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

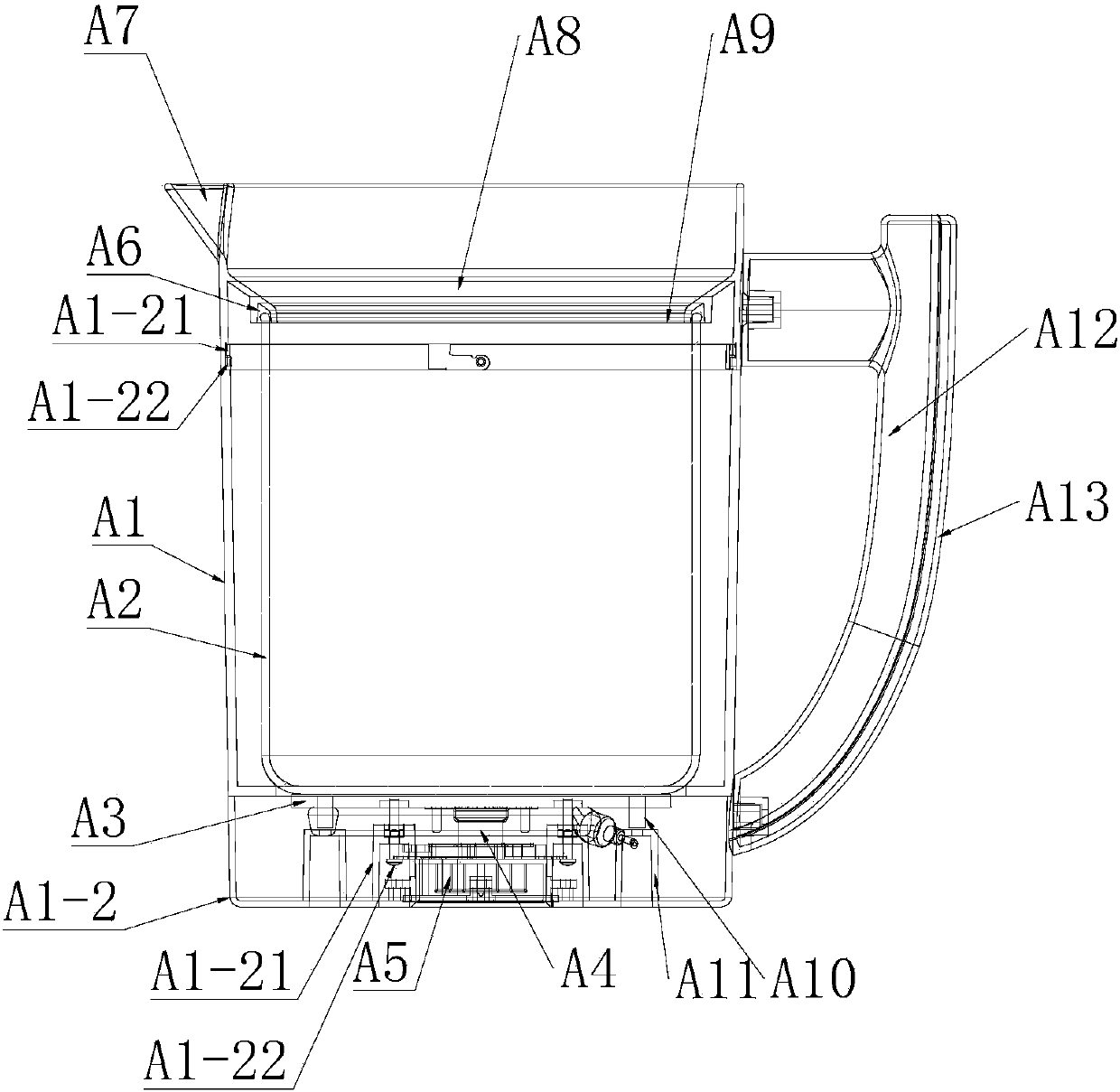

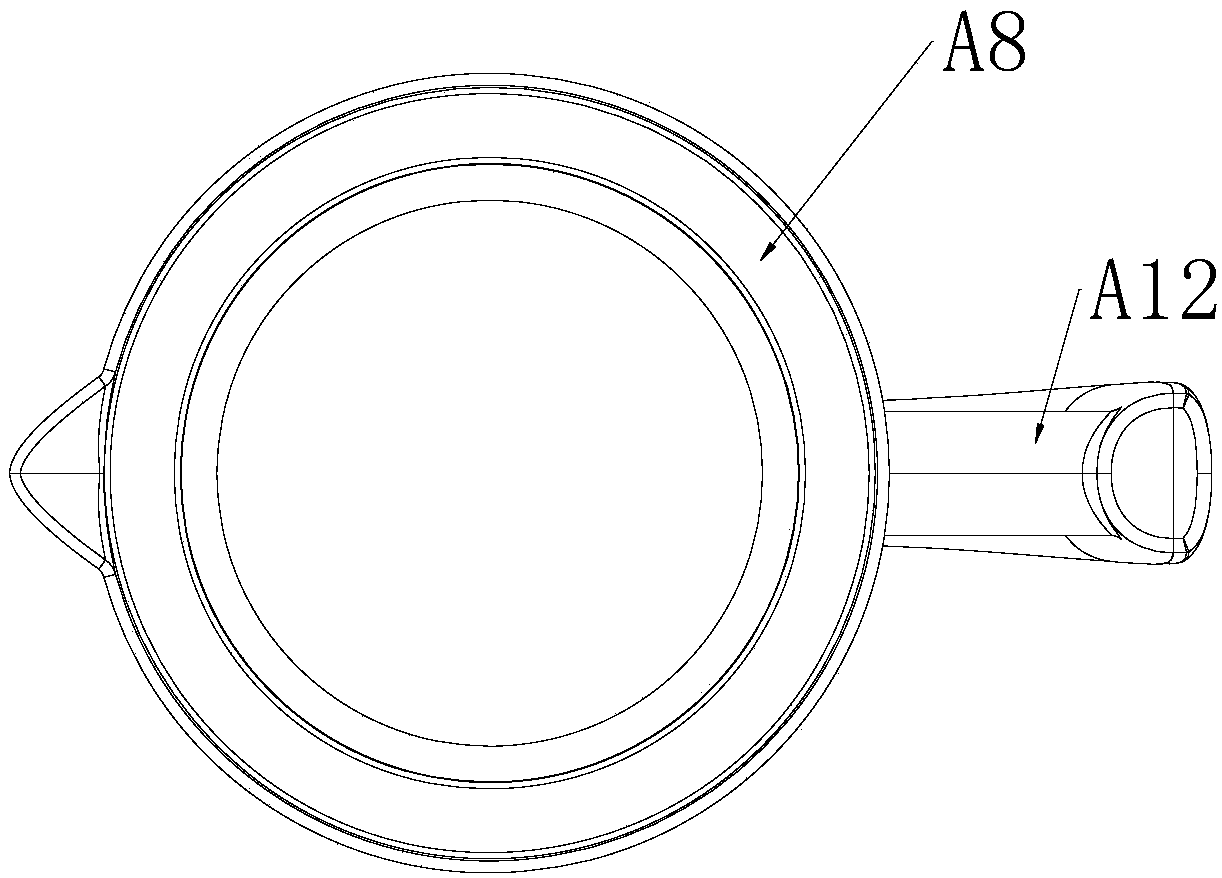

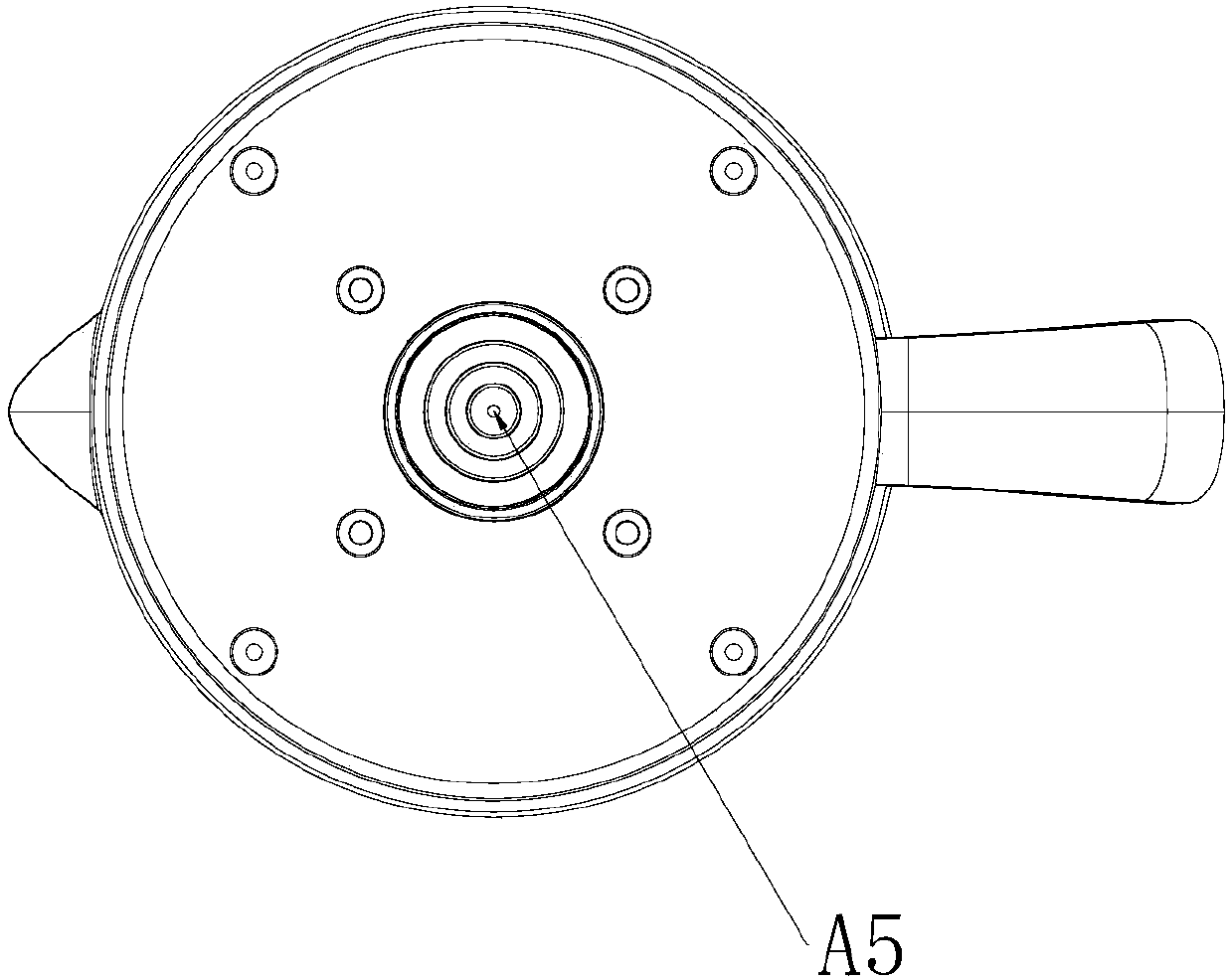

[0038] like Figure 1-Figure 5 As shown, the present invention is a high-efficiency energy-saving glass health pot, including a shell A1 and a glass liner A2 with a sealed bottom, a heating plate A3, a thermostat A4 and a connector A5. The thermostat A4 is set on Between heating plate A3 and connector A5. Wherein, the glass liner is a flat-bottomed glass liner, and the heating plate is closely attached to the flat bottom surface of the glass liner. The casing A1 includes a cylinder-A1-1 sleeved outside the glass liner and a bottom box A1-2 connected and assembled at the bottom of the cylinder-body. The heating plate, temperature controller and connector are arranged between the bottom box and the glass liner. Between them, the side of the connector A5 is provided with an ear piece A5-1, and the ear piece is provided with a screw hole A5-2, and is fixed to the middle of the bottom box by the screw in the screw hole. A pressing support mechanism is provided below the heating p...

Embodiment 2

[0043] like Figure 6-Figure 10 As shown, in this embodiment, the high-efficiency and energy-saving glass health pot includes a shell B1 and a glass liner B2 with a sealed bottom, a heating plate B3, a temperature controller B4 and a connector B5. The heating plate is arranged under the glass liner, and the bottom of the heating plate is provided with a top pressure support mechanism, which drives the heating plate to be in close contact with the bottom of the glass liner to speed up the heating speed. Among them, the shell B1 includes a cylinder body B1-1 and a pressure sleeve B1-2 that is movably connected to the upper part of the cylinder body II. elastic components and / or adjustable fasteners up and down. In this embodiment, the bottom support includes a second support B6 with a built-in cavity arranged at the bottom of the cylinder second. As the power source for providing the upper and lower pressing force, the pressing support mechanism adopts the form of locking part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com