A kind of preparation method of the nano germanium particle of surface passivation

A technology of nano-germanium and particles, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as hindering electron transport between particles, reducing the electrical properties of particles, and unfavorable particle applications. The effect of optimizing the preparation process and flow, reducing the number of defect states, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

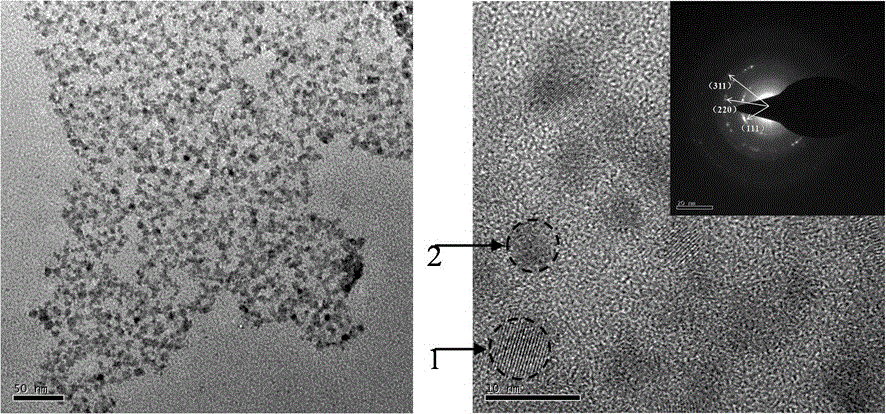

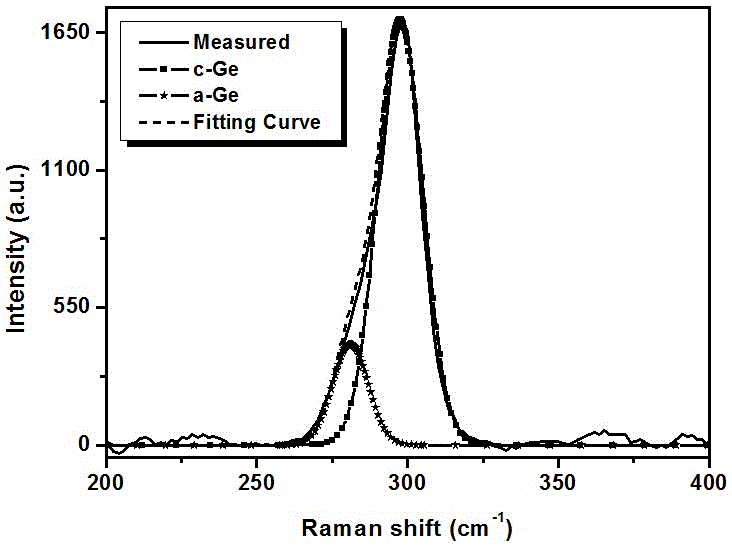

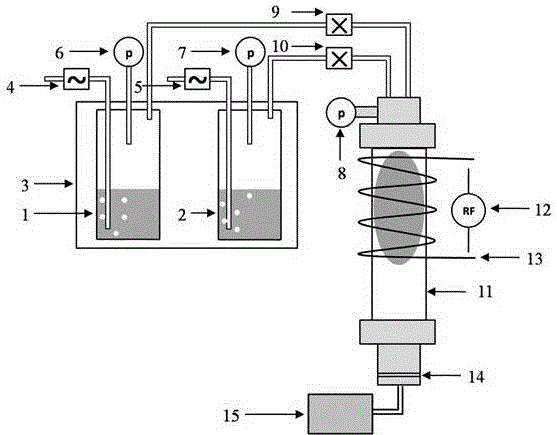

[0014] Such as figure 1 The schematic diagram of the one-step method for synthesizing surface-passivated nano-germanium particles, the bubbler (1) and the bubbler (2) are respectively filled with liquid germanium tetrachloride and water, and placed in a constant temperature water tank (3) , the water temperature is maintained at 50°C; argon gas is passed into the bubbler (1), and the flow meter (4) is adjusted to maintain the flow rate of argon gas at 20 sccm; the hand valve (9) is opened and the opening size is adjusted so that the pressure gauge (6 ) at 200kPa; argon carries germanium tetrachloride gas molecules into the quartz glass tube (11), and adjusts the pumping speed of the mechanical pump (15) to maintain the pressure gauge (8) at 200Pa; turn on the radio frequency power supply (12), and set the power Set at 60W, the induction coil (13) generates a high-frequency electromagnetic field to ionize germanium tetrachloride to form plasma; after the glow is stabilized, arg...

Embodiment 2

[0018] Such as figure 1 The schematic diagram of the one-step method for synthesizing surface-passivated nano-germanium particles is shown. The bubbler (1) and the bubbler (2) are respectively filled with liquid germanium tetrabromide and water, and placed in a constant temperature water tank (3). , the water temperature is maintained at 70°C; argon gas is passed into the bubbler (1), and the flow meter (4) is adjusted to maintain the flow rate of argon gas at 20 sccm; the hand valve (9) is opened and the opening size is adjusted so that the pressure gauge (6 ) at 200kPa; argon carries germanium tetrabromide gas molecules into the quartz glass tube (11), and adjusts the pumping speed of the mechanical pump (15) to maintain the pressure gauge (8) at 200Pa; turn on the radio frequency power supply (12), and set the power Set at 70W, the induction coil (13) generates a high-frequency electromagnetic field to ionize germanium tetrabromide to form plasma; after the glow is stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com