Method for reducing steel slag adhesion in ultra-low carbon steel smelting process

A technology of ultra-low carbon steel and smelting process, applied in the field of molten steel refining, which can solve problems such as the impact of molten steel quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

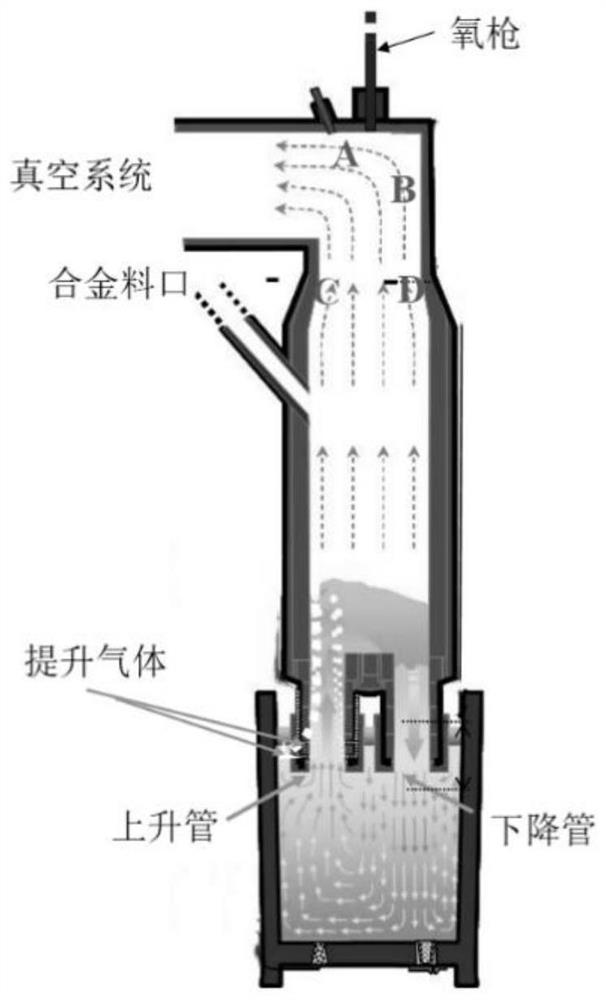

Method used

Image

Examples

Embodiment 1

[0034] The composition requirements of ultra-low carbon steel used in this embodiment are as shown in Table 1:

[0035] Table 1 Ultra-low carbon steel composition requirements

[0036]

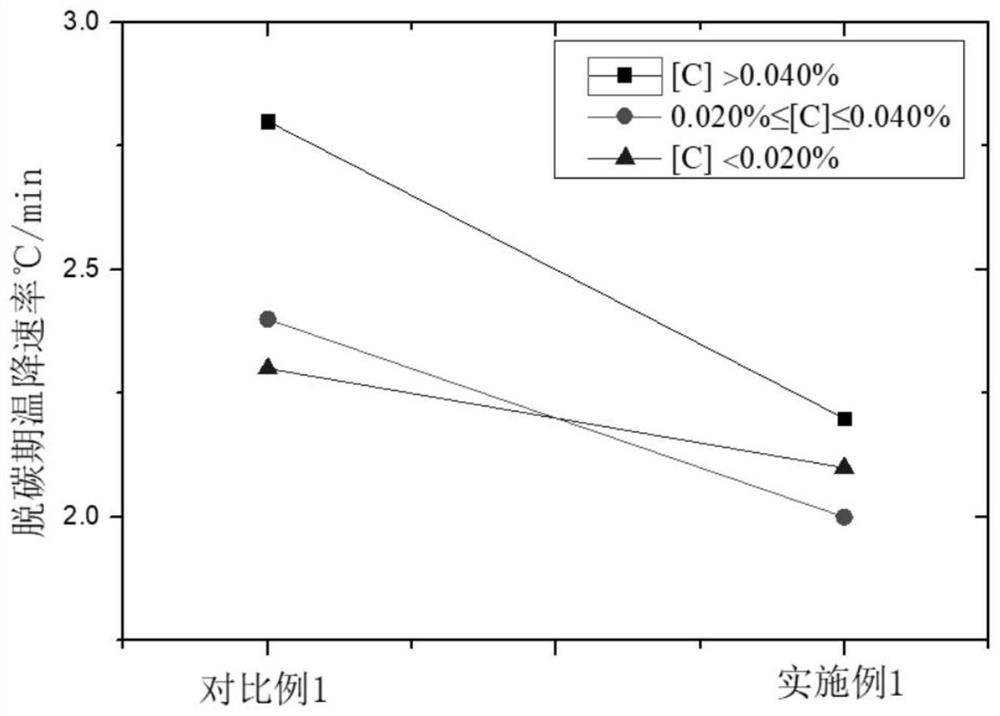

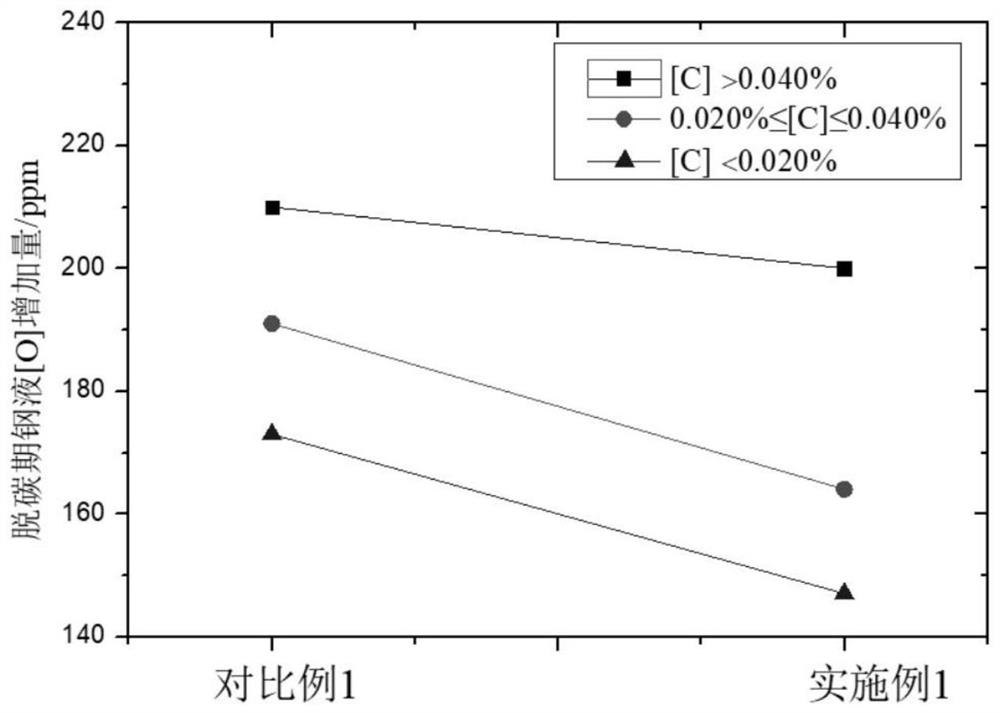

[0037] In the production of ultra-low carbon steel in a 110t steel ladle, according to the specific carbon content in the ultra-low carbon steel, different oxygen lance control parameters are used during the decarburization period to perform oxygen blowing operation, see Table 2 for details:

[0038] Table 2 Oxygen lance control parameters

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com