Unconfined compression test sample preparation device

A compression test and confinement technology, applied in the preparation of test samples, etc., can solve the problems of low yield, pores and cracks, uneven filling, etc., and achieve the effect of simple production, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

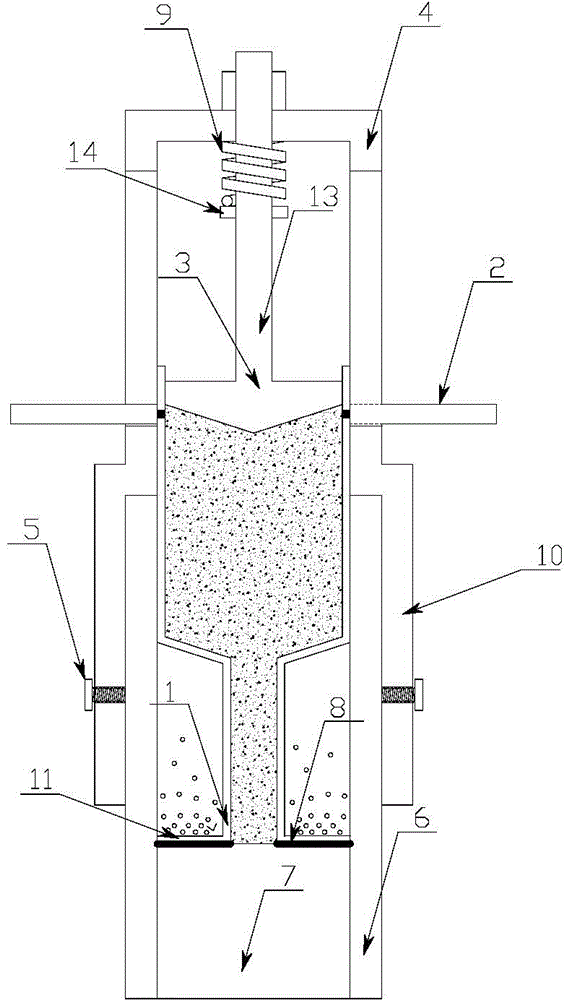

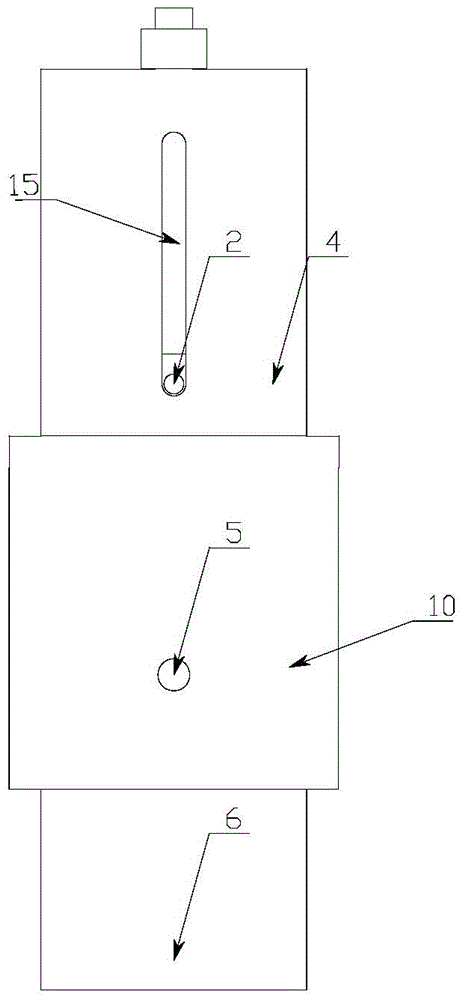

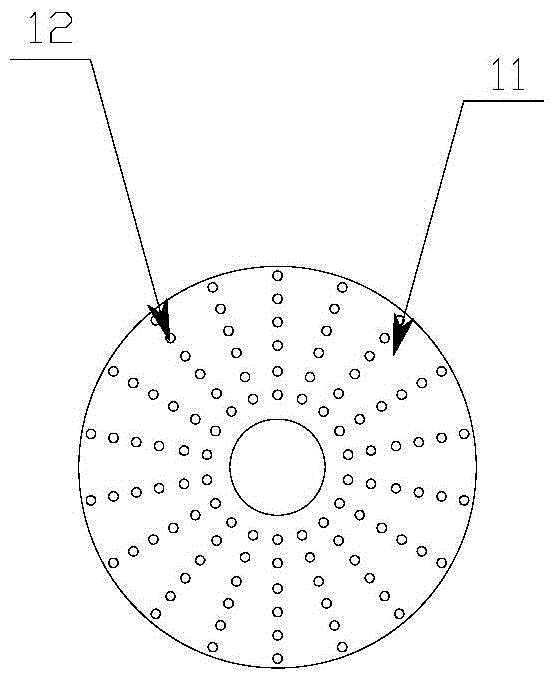

[0016] See Figure 1 ~ Figure 4 , an unconfined compression test sample preparation device, including a cylinder mold 6, the cylinder mold 6 is provided with an internal bottom support 7 and an internal pressure head 16, and a goblet-shaped funnel is inserted in the cylinder mold 6 1. The upper part of the funnel 1 is a cylindrical storage part with a larger diameter, and a cylindrical export part with a smaller diameter is provided below the storage part 1, and an export port and an outlet along the Radially extending ventilating ring plate 11 turned outwards is provided with a plurality of evenly distributed venting holes 12 on the venting ring plate 11, filter paper 8 is arranged on the lower surface of the venting ring plate 11, and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com