Clamp for electrified stretching

A clamp and clamp body technology, used in the field of tensile testing, can solve the problems of limited sample size, low versatility, low tensile strength, etc., and achieve the effects of high tensile strength, expanded use range, and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

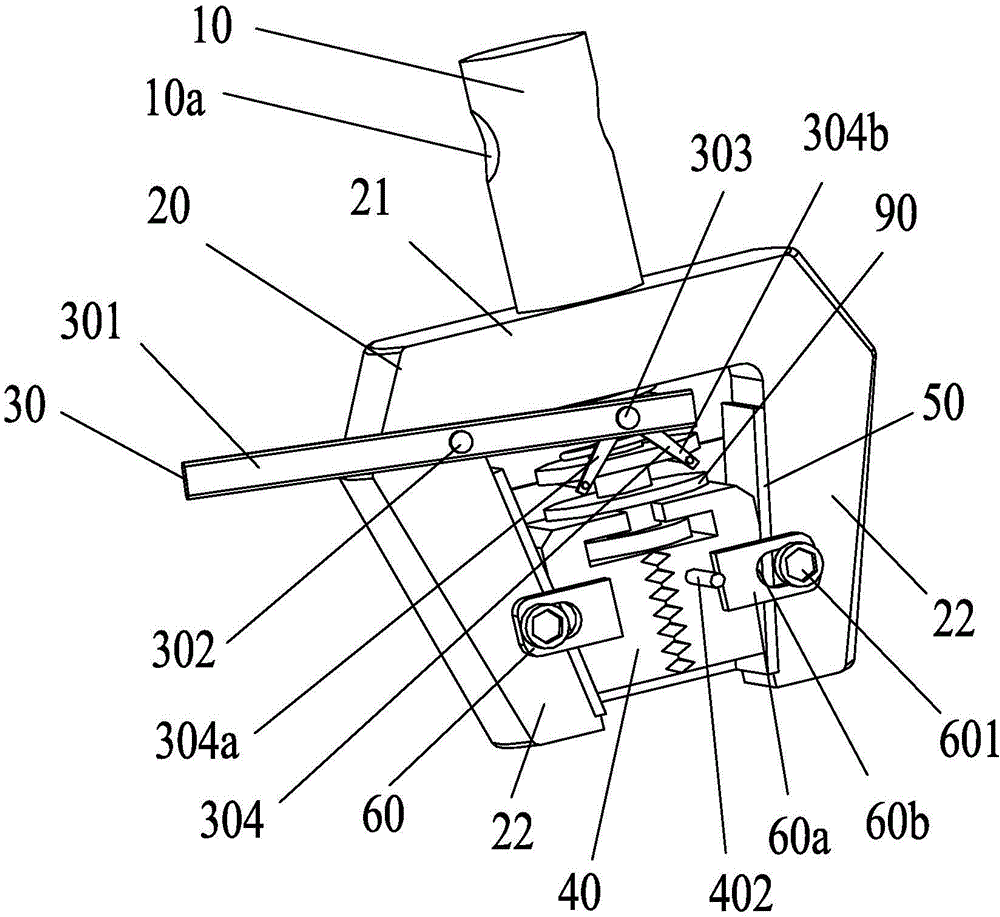

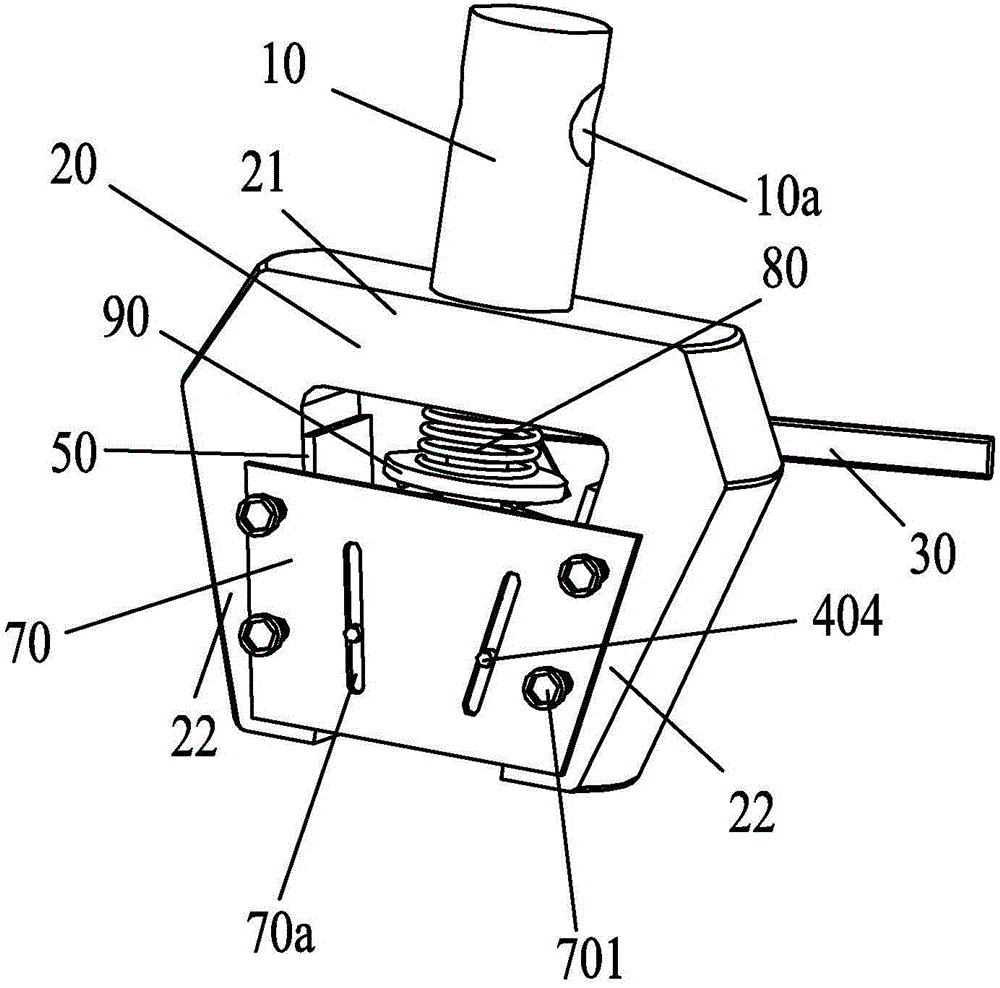

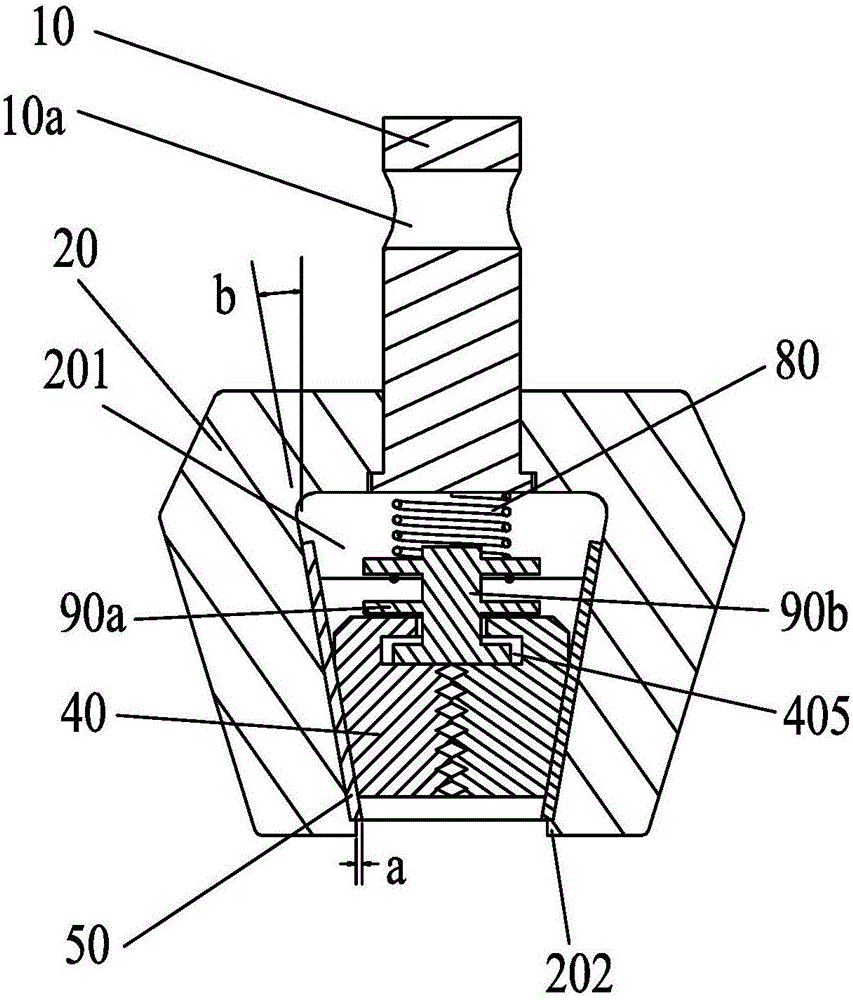

[0033] An embodiment of the present invention provides a clamp for electrified stretching, which is suitable for connection with a tensile testing machine, see Figure 1-6 , the clamp includes: a clamp handle 10, a clamp body 20, a release device 30, two clamping blocks 40, two insulating partitions 50, an insulating limiter 60, an insulating barrier 70, a spring 80 and an insulating pretensioning block 90 .

[0034] The clip body 20 includes a bottom 21 and two side arms 22 disposed at two ends of the bottom 21 , an opening 201 is formed between the bottom 21 and the two side arms 22 . One end of the clamp handle 10 is connected to the bottom 21 , the other end of the clamp handle 10 is connected to the tensile testing machine, and the side arm 22 and the clamp handle 10 extend from the bottom 21 in opposite directions.

[0035] The opening 201 includes a base defined by the bottom 21 and side walls defined by the side arms 22 , the width of the opening 201 (ie the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com