Steel pipe pressure test device and its test method

A technology of pressure resistance detection and steel pipe, applied in the direction of applying stable tension/pressure to test the strength of materials, transportation and packaging, conveyor objects, etc., can solve the problems of instability, low work efficiency, detection failure, etc., to achieve the overall structure Reasonable and ingenious design, high work efficiency, and powerful detection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

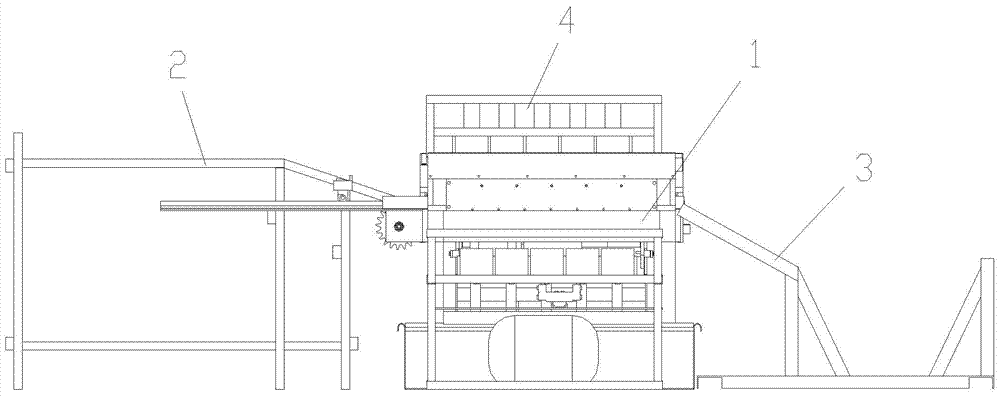

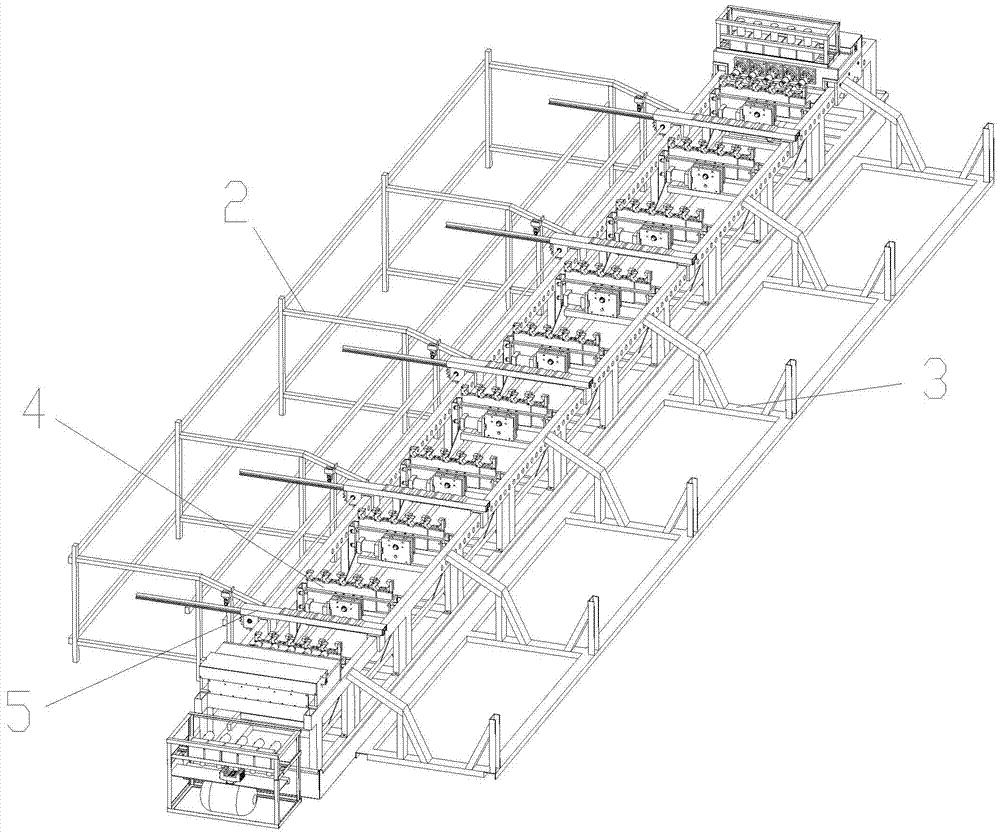

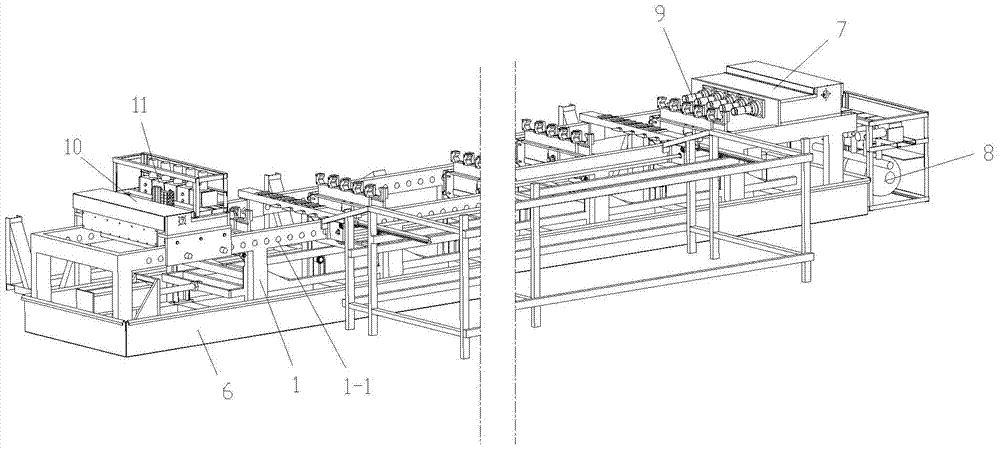

[0038] Referring to the accompanying drawings: the steel pipe pressure test device in this embodiment includes a support frame 1, the front and rear sides of the support frame 1 are respectively connected with a loading frame 2 and a blanking frame 3, and a positioning fixture 4 is installed on the support frame 1, and the positioning fixture 4 and the feeding frame 2 are installed with a feeding translation frame 5, a water tank 6 is installed at the bottom of the support frame 1, a fixed water pressure head 7 is installed at the left end of the support frame 1, and the fixed water pressure head 7 is connected with a water inlet pressure accumulator 8 and the sealing head 9, the right end of the support frame 1 is equipped with a movable hydraulic head 10, and the movable hydraulic head 10 is equipped with a drainage system 11 and a sealing head 9;

[0039]The loading rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com