Electric wire extrusion molding process parameter optimization method for vehicles based on chaotic wavelet neural network

A wavelet neural network and optimization method technology, applied in neural learning methods, biological neural network models, etc., can solve the problem that the wire diameter and surface finish cannot be accurately controlled, and it is difficult to determine the production extrusion of low-smoke halogen-free refractory wires for vehicles. Plastic process parameters and other issues to achieve the effect of avoiding falling into a local minimum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

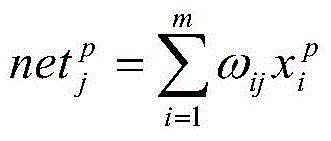

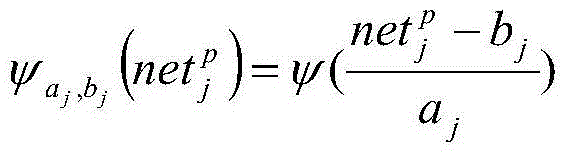

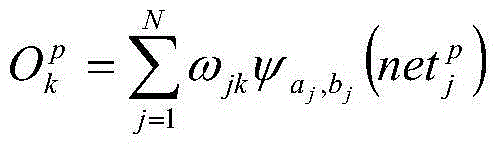

Method used

Image

Examples

Embodiment Construction

[0069] The technical solution of the present invention will be further described in detail below in conjunction with examples.

[0070] The present invention introduces the CWNN algorithm into the automotive low-smoke halogen-free refractory wire extrusion system, and establishes a predictive model of output (wire diameter, surface finish) based on statistics and analysis of real data in the production process; chaos theory is used Optimize the initial values of the network parameters of the prediction model, and add nonlinear self-feedback items in the adjustment process of the network parameters, and then learn and train the prediction model to obtain a stable prediction model; on the basis of the trained wavelet neural network prediction model The parameter optimization strategy based on chaos algorithm is established on the above, the object to be optimized in the extrusion system is proposed, and the optimized value is determined according to the optimized optimal performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com